Patrick B

Newbie

- Messages

- 8

Hello guitarlings

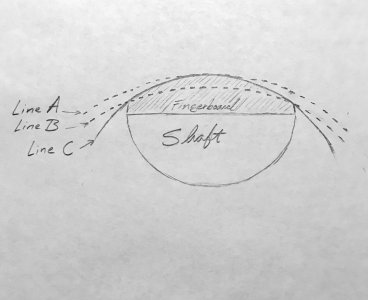

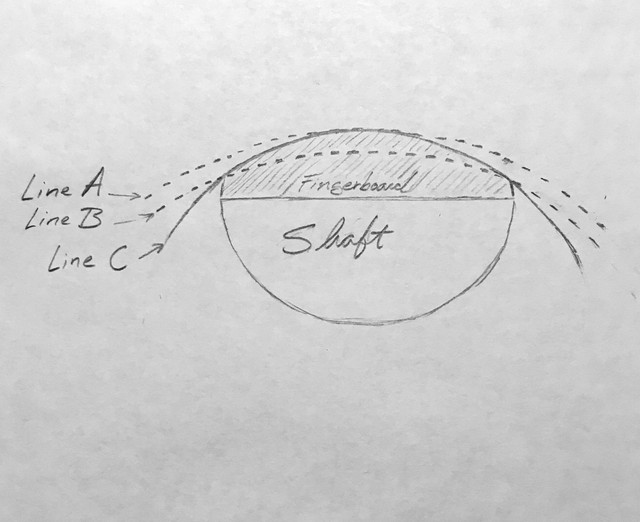

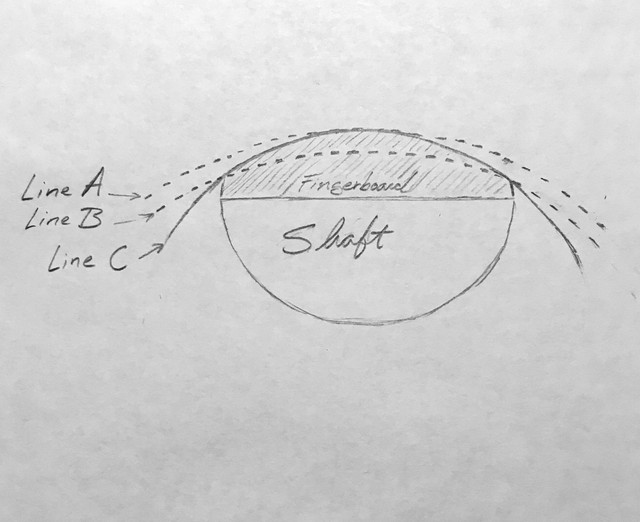

I've got a question about how Warmoth cuts its fingerboard radius. My question is best summed up with this picture:

If solid line C represents a given low radius neck and dotted lines A & B represent a given large radius neck, does Warmoth cut the fingerboards like line A or like line B?

Asked in another way, for any two given radius sizes, is the center of the fingerboard held constant while the sides vary, or are the sides held constant while the center thickness varies?

The reason I ask: if Warmoth cuts like lines A and C (as opposed to B and C), then small radius necks will definitely make the shoulders feel thinner.

Forgive the fixation on a small detail. I've just been going around measuring different necks trying to figure out why I like the ones I like.

I've got a question about how Warmoth cuts its fingerboard radius. My question is best summed up with this picture:

If solid line C represents a given low radius neck and dotted lines A & B represent a given large radius neck, does Warmoth cut the fingerboards like line A or like line B?

Asked in another way, for any two given radius sizes, is the center of the fingerboard held constant while the sides vary, or are the sides held constant while the center thickness varies?

The reason I ask: if Warmoth cuts like lines A and C (as opposed to B and C), then small radius necks will definitely make the shoulders feel thinner.

Forgive the fixation on a small detail. I've just been going around measuring different necks trying to figure out why I like the ones I like.