Ddbltrbl

Hero Member

- Messages

- 755

So...

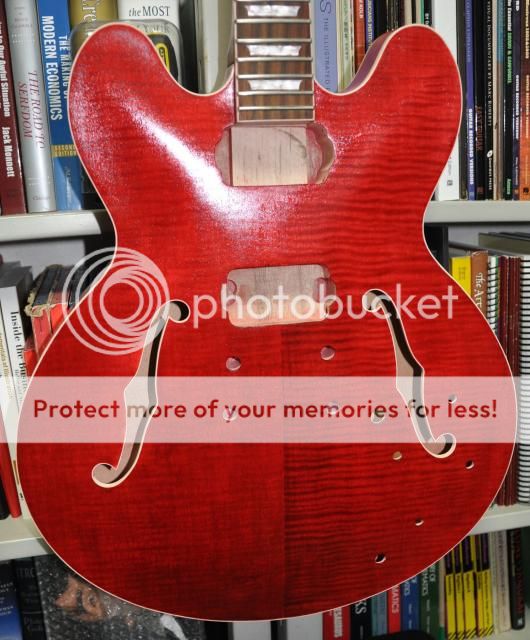

After seeing Magicbisket's posts here GFS 335 Kit, here Just Out of the Box, and here Work in Progress I determined I really needed a 335 and that I should try this for myself. :dontknow:

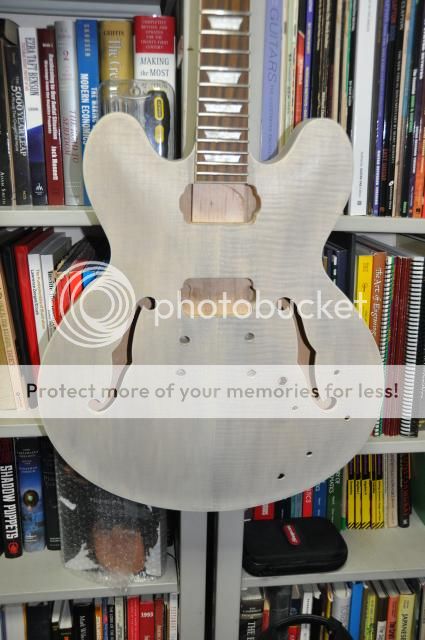

I got the kit last August and really haven't found any time to put towards it until this week. The kit was complete and arrived in Yokohama in good condition. When I opened it I found several little issues, but I was generally happy so far. The biggest concerns I noticed immediately were:

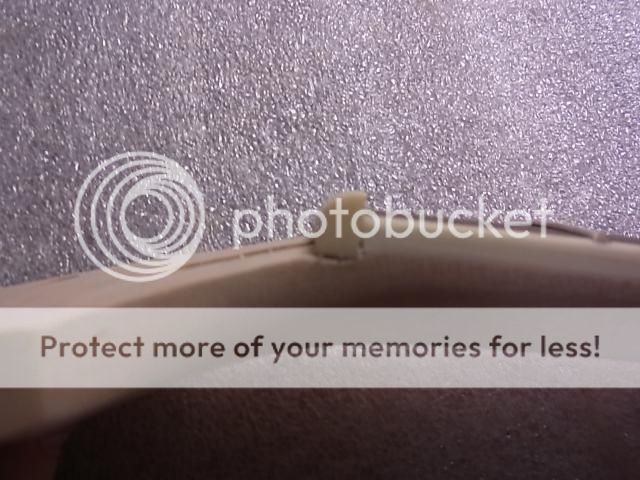

1. Horrid nut installation:

Sorry I didn't get a clearer picture. I really wanted to replace the nut anyway, but the original nut is installed so deep and uneven that it will take some work. Plus the headstock was done so that it undercuts the nut by about 1/3rd. You can't really see it in the picture.

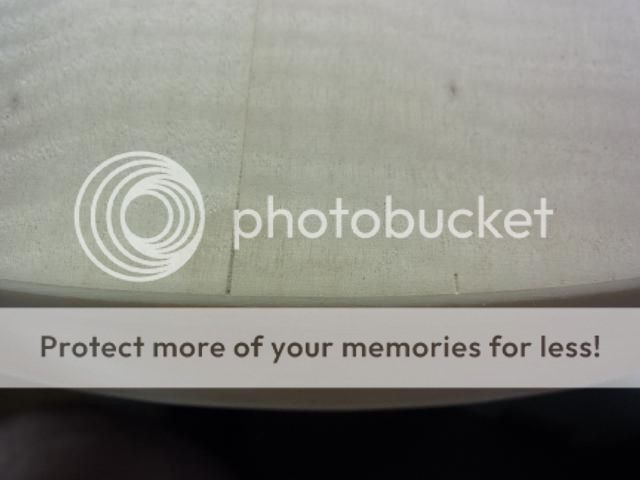

2. Rough neck pocket:

I'll fix that so it's not noticeable, but makes you wonder about the setup.

3. Various scratches and gouges, and similar glue issues to what Magicbisket ran into with his.

Fortunately I have the benefit of his experience and knew to check first. Bottom line; if you're going to do one of these kits, expect to do a lot of prep work before it goes together.

The hardware is pretty cheap (to be expected in a $200 kit) so I plan to replace a lot of it. Particularly the pickups, jack and 3-way switch. I also noticed that the bridge is non-standard. The posts are larger and the thread size different than the standard Gibson, so I maybe stuck with it. It's not too bad, but I will probably at least replace the saddles. And, I think I will replace the tuners with mini Schallers.

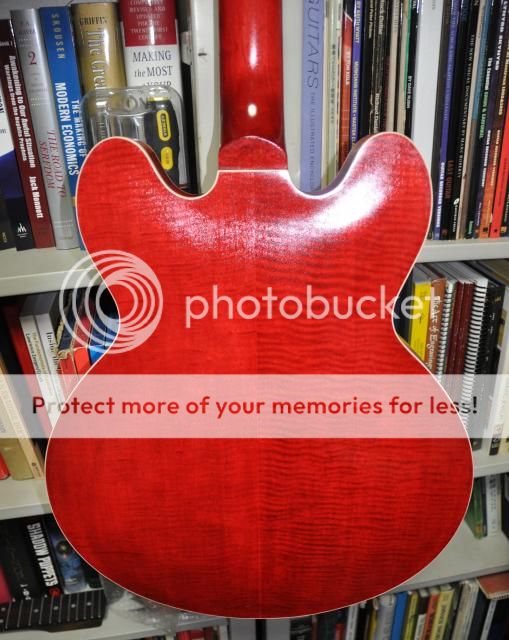

I spent 3 evenings sanding out all the problems with the body and getting all the surface prep the way I like it. Besides the scratches and glue, I found a number of areas were the binding or the channel was uneven in thickness. But, I think I've finally got it all ready to go.

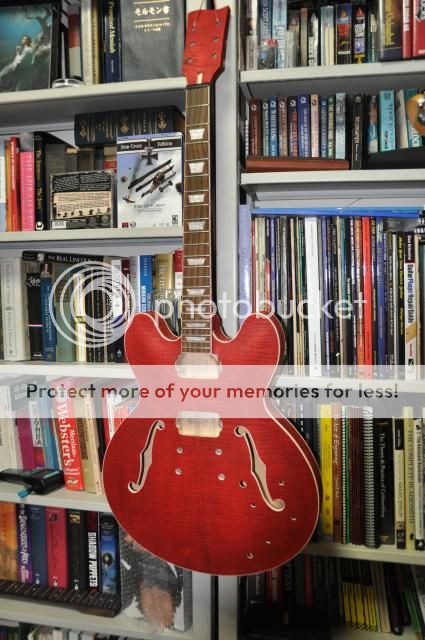

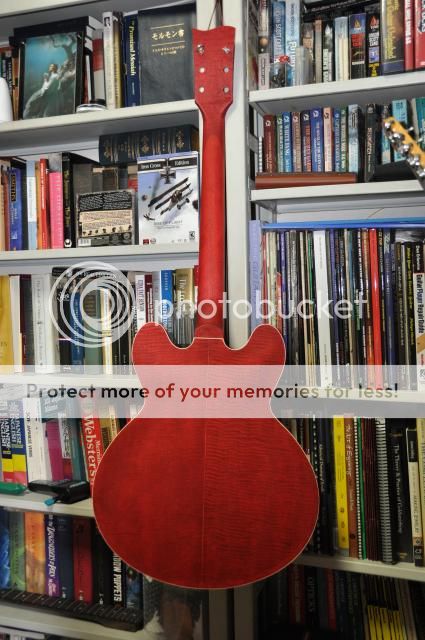

I plan to do the whole guitar in a red dye, so I think I will glue in the neck before I start the finish. Anyway, I didn't care for the headstock as it came, so I did a little modification. Here is the orginal, followed by my mod.

As you can see, I installed a Earvana nut. I had to put quite a thick shim under it to make it work. You can also see the poor shape of the right side of the headstock that I still have to clean up.

I also discovered that it is 12 3/8" from the nut to the 12 fret, but closer to 12 3/4" from the 12th fret to the center of the bridge. Will check tomorrow whether I can move the neck 3/8" closer to the bridge without causing problems for the neck pickup. I also just noticed on GFS's site that the current kits don't have the bridge holes pre-drilled, so this wouldn't be a problem. Nor would replacing the bridge.

:dontknow:

Anyway, I don't think I would recommend this kit to anyone without at least some experience! :sad1:

After seeing Magicbisket's posts here GFS 335 Kit, here Just Out of the Box, and here Work in Progress I determined I really needed a 335 and that I should try this for myself. :dontknow:

I got the kit last August and really haven't found any time to put towards it until this week. The kit was complete and arrived in Yokohama in good condition. When I opened it I found several little issues, but I was generally happy so far. The biggest concerns I noticed immediately were:

1. Horrid nut installation:

Sorry I didn't get a clearer picture. I really wanted to replace the nut anyway, but the original nut is installed so deep and uneven that it will take some work. Plus the headstock was done so that it undercuts the nut by about 1/3rd. You can't really see it in the picture.

2. Rough neck pocket:

I'll fix that so it's not noticeable, but makes you wonder about the setup.

3. Various scratches and gouges, and similar glue issues to what Magicbisket ran into with his.

Fortunately I have the benefit of his experience and knew to check first. Bottom line; if you're going to do one of these kits, expect to do a lot of prep work before it goes together.

The hardware is pretty cheap (to be expected in a $200 kit) so I plan to replace a lot of it. Particularly the pickups, jack and 3-way switch. I also noticed that the bridge is non-standard. The posts are larger and the thread size different than the standard Gibson, so I maybe stuck with it. It's not too bad, but I will probably at least replace the saddles. And, I think I will replace the tuners with mini Schallers.

I spent 3 evenings sanding out all the problems with the body and getting all the surface prep the way I like it. Besides the scratches and glue, I found a number of areas were the binding or the channel was uneven in thickness. But, I think I've finally got it all ready to go.

I plan to do the whole guitar in a red dye, so I think I will glue in the neck before I start the finish. Anyway, I didn't care for the headstock as it came, so I did a little modification. Here is the orginal, followed by my mod.

As you can see, I installed a Earvana nut. I had to put quite a thick shim under it to make it work. You can also see the poor shape of the right side of the headstock that I still have to clean up.

I also discovered that it is 12 3/8" from the nut to the 12 fret, but closer to 12 3/4" from the 12th fret to the center of the bridge. Will check tomorrow whether I can move the neck 3/8" closer to the bridge without causing problems for the neck pickup. I also just noticed on GFS's site that the current kits don't have the bridge holes pre-drilled, so this wouldn't be a problem. Nor would replacing the bridge.

:dontknow:

Anyway, I don't think I would recommend this kit to anyone without at least some experience! :sad1: