Ok. Mini pots and roller knobs.

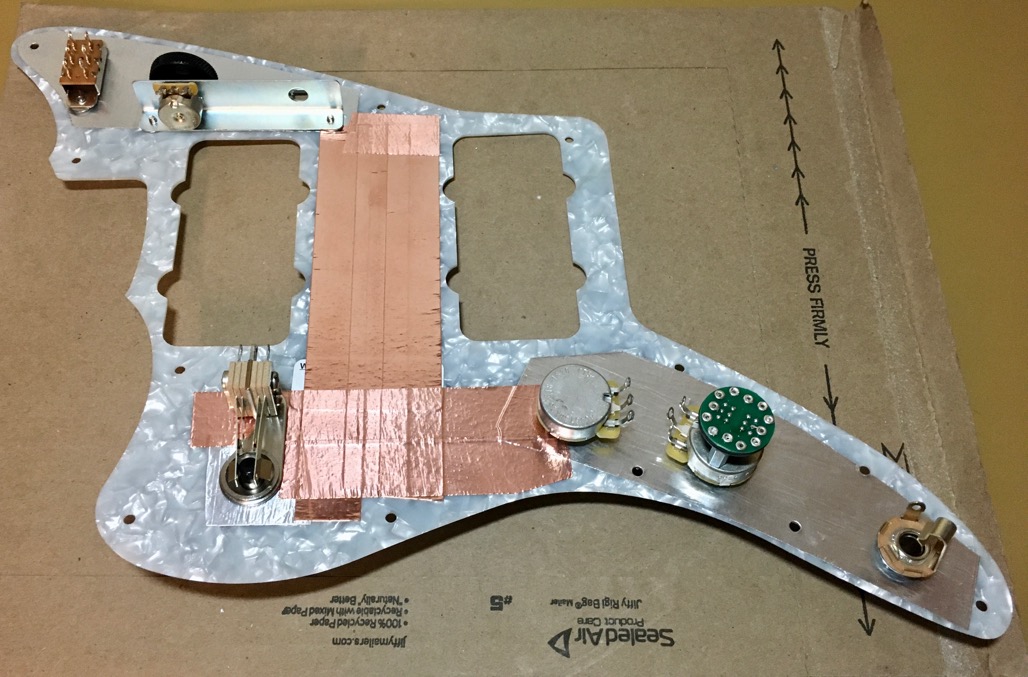

This is the standard USA spec Jazzmaster hardware:

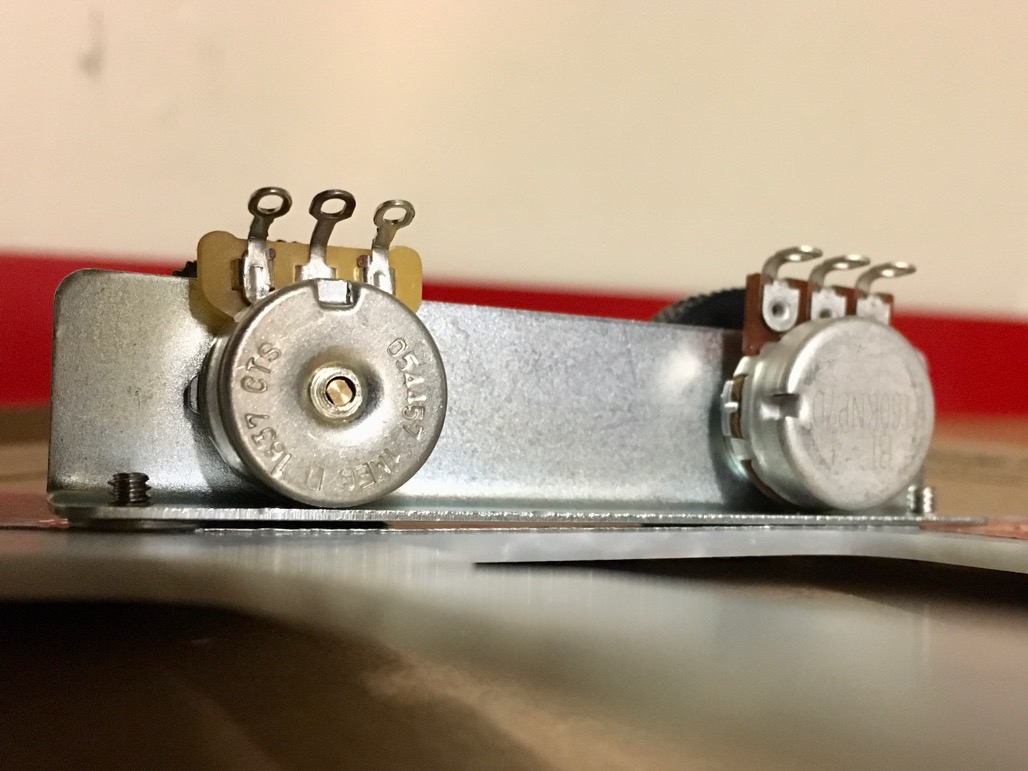

The pot shaft is 4mm, which is pretty darn tiny. Trying to find 4mm shaft pots in values other than 1Meg linear and 50k linear (the standard rhythm circuit compliment) is futile. I tried. Like the ROUS's, I don't believe they exist.

However Japanese Jazzmasters use a pot with a larger 6mm shaft. So the Japanese spec roller knobs open up a lot more possibilities. It still took some pretty heavy digging through the Mouser inventory to find something that would also fit in the Jazzmaster control route, and I ordered more than one that was a failure, but I eventually had success!

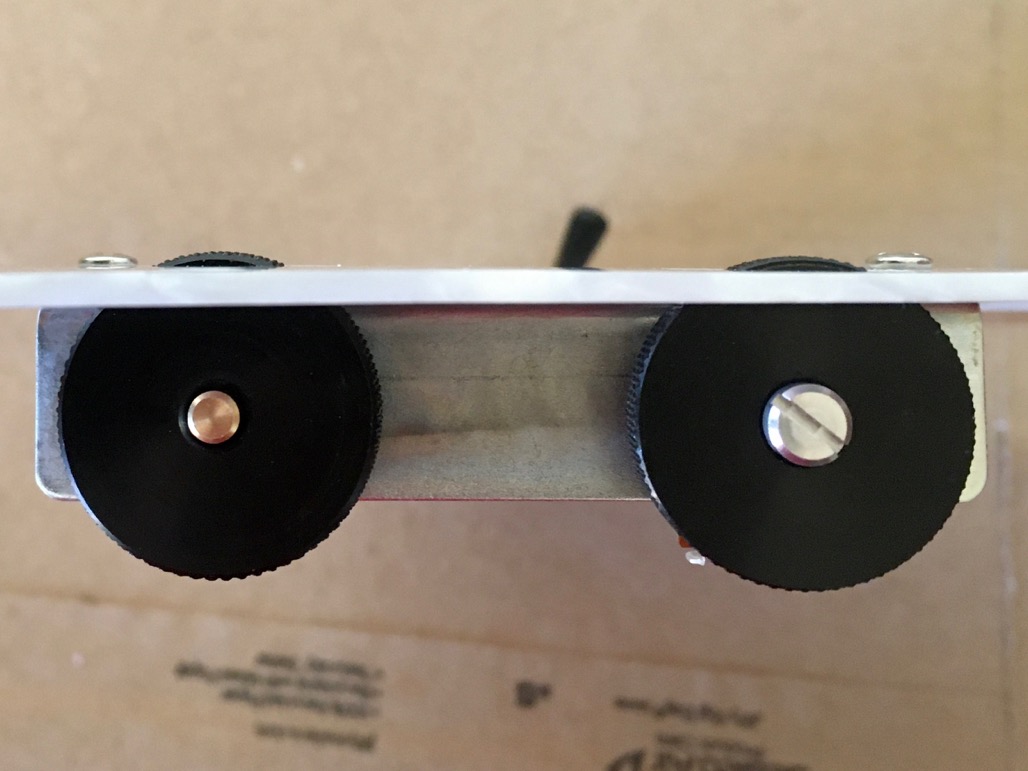

Japanese Spec Roller Knob, Fender P/N 0264227000

(I ordered them from Darren Riley, but they no longer show in his inventory.....?)

<Note to readers from The Future: the pots linked below ended up being wrong after all. See update on 5/25/2020 for info and links to the actual correct pots......>

Compatible 250k audio taper pot, Mouser P/N 858-P160KNP0EC15A250

https://www.mouser.com/ProductDetail/tt-electronics/p160knp-0ec15a250k/?qs=56eeD6vBg8hhR%252bJRCDE9aA%3D%3D&countrycode=US¤cycode=USD

Compatible 500k audio taper pot (this is the one I am using), Mouser P/N 858-P160KNPC15A500K

https://www.mouser.com/ProductDetail/tt-electronics/p160knp-0ec15a500k/?qs=mJjUQczmFniyDjTw9iQXgA%3D%3D&countrycode=US¤cycode=USD

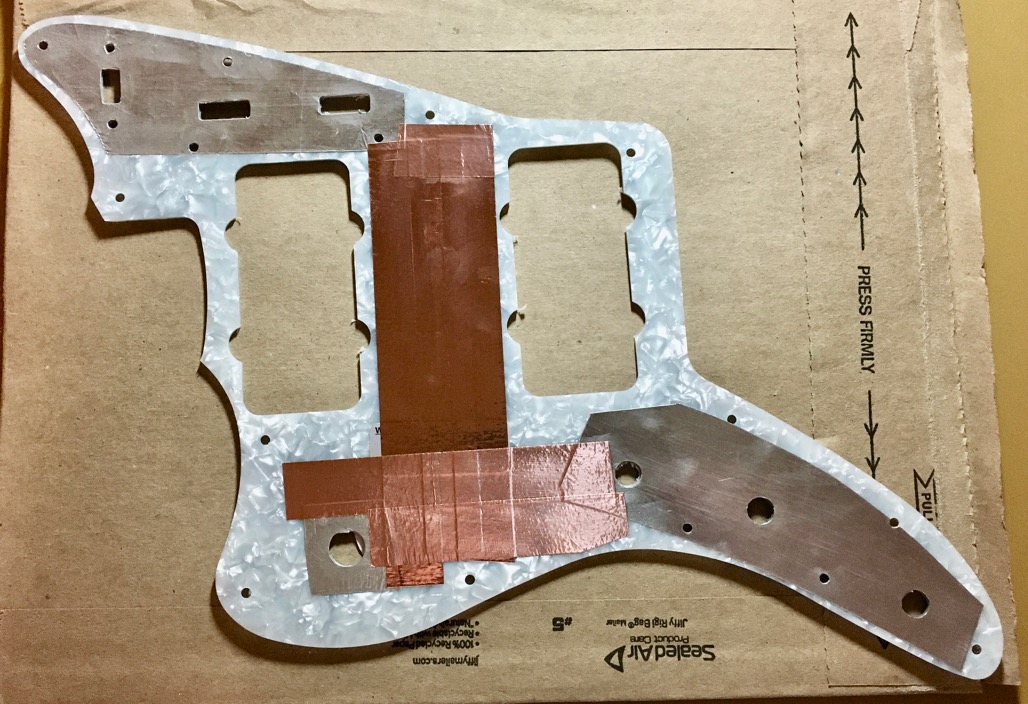

And I am using this bracket from All Parts:

https://www.allparts.com/products/ap-0652-pot-bracket-for-jazzmaster-pickguards

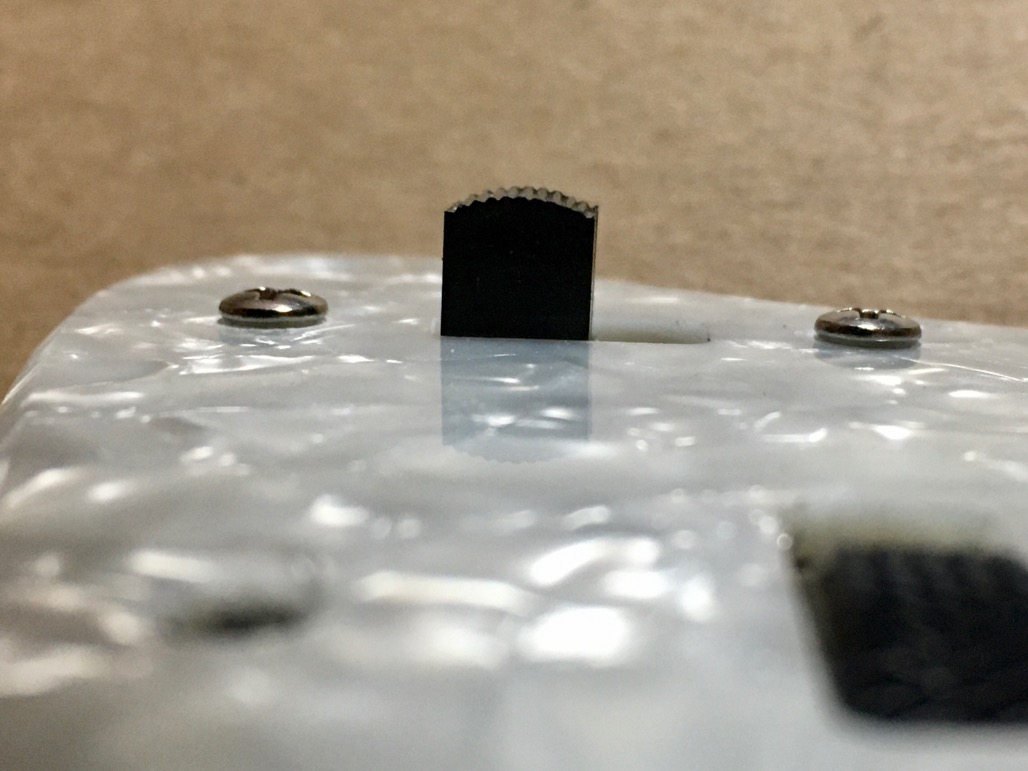

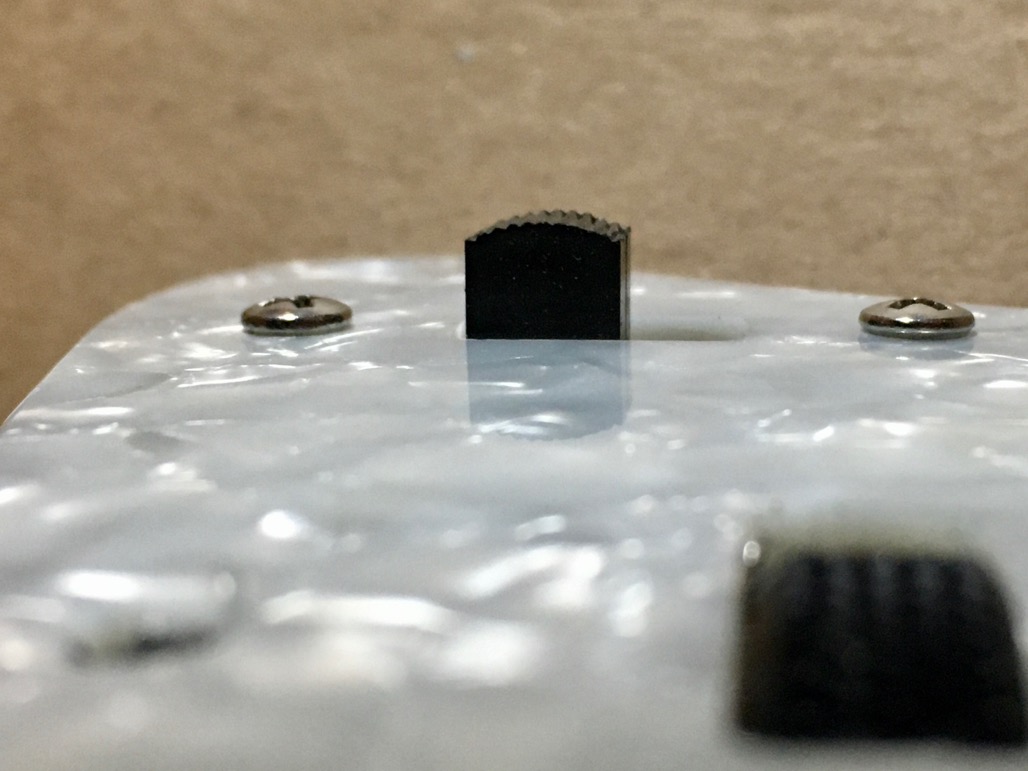

It fits in the bracket with no modification, and a single M7 washer got it sitting properly. The shaft still sets a little higher than the standard pot; hopefully that will not cause any conflict with the route. A can use another washer to drop it further, but that puts the bottom of the pot right on the edge of the pickup cavity. We will see what happens when the body arrives.

The dimensions of the Japanese knob are ever so slightly different from the USA spec knob. The diameter is slightly smaller and it is also a bit thinner. Centering it in the window makes the thickness difference pretty un-noticeable. Slipping a #4 washer on the bracket mounting screw on the volume pot side, but NO washer on the tone pot side, compensates for the diameter difference and puts both knobs protruding equally through the pickguard.

So, there's one hurdle jumped :headbang1: