Cagey

Mythical Status

- Messages

- 24,425

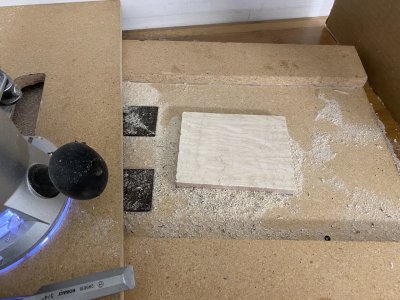

If/when you find a plug cutter, make sure the plug you end up with will fit in a standard Forstner bit diameter. Makes drilling the fretboard nice and clean and leaves a flat-bottomed hole, both of which are critical. Don't want to have to replace a fretboard :laughing7: