You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flake Finish Jazzmaster

- Thread starter Rick

- Start date

Scab Pickens

Senior Member

- Messages

- 568

1 3/4

I absolutely love the 1-3/4" nut width on my standard thin Tele neck. The next one will be a SRV or, possibly, Wolfgang profile. Looking for something with a little more beef for my dual humbucker Tele build. I'm a Gibson J-45 acoustic guy at heart, so I dig the chunky necks.

Can't wait to see the end result on this one!

bagman67

Epic Member

- Messages

- 9,227

To those who oppose a bling-y neck, I submit for your consideration Joe Gore's Kitschcaster, which is bound AND has the silver flake paintjob on the ENTIRE neck to match the body, and - in my opinion - looks pretty frickin rad:

tonefiend.com

tonefiend.com

Kitschcaster: An Experimental Fender/Gretsch Hybrid - tonefiend.com

Joe Gore from tonefiend.com demonstrates a new DIY guitar: the Kitschcaster, an odd Fender/Gretsch hybrid.

Rick

Epic Member

- Messages

- 7,150

Parts List. As of July 14 all the warmoth parts have been ordered. Man there are so many details to pay attention to!

It took 50 days of planning to get to this point. Now it's execution!

Warhead Guitar Neck

Construction Modern

Shaft Wood Quartersawn Maple

Fretboard Wood Indian Rosewood

Nut Width 1-3/4" (44mm) - Wide

Right / Left Handed Right-Handed

Neck Back Profile Wolfgang

Fretboard Radius 10" - 16" Compound

Number of Frets 21

Scallops None

Binding None

Fret Size & Material SS6150 - Wide & Tall (Stainless)

Tuner Hole Size Schaller/Modern Fender/Sperzel (25/64")

Inlay Shape Split Diamond

Inlay Material White Pearloid

Side Dots White Side Dots

String Nut Standard Nut - GraphTech White TUSQ XL

Mounting Holes Standard 4-Bolt

Neck Heel Shape Strat® Shape

Finish Vintage Tint Gloss

Jazzmaster® Replacement Guitar Body

Construction Chambered

Core Wood **Extra Light Poplar**

Lam Top Wood Alder

Right / Left Handed Right-Handed

Control Cavity Top Rout

Neck Pickup Rout Humbucker

Middle Pickup Rout Humbucker

Bridge Pickup Rout Humbucker

F-Holes None

Jack Rout 7/8" (22mm) Side Jack Hole

Bridge Rout Type Hardtail

Bridge Rout Fender American Standard Strat® Flat Mount

Mounting Holes Standard 4-Bolt

Neck Pocket Shape Strat®

Body Contours Forearm Contour, Tummy Cut

Binding and Edge Decorations Pearloid Binding (Drop Top)

Battery Box None

Paint Category Flake

Inferno Flake

Gloss

Jazzmaster® Pickguard

Color / Material White Pearl

Right / Left Orientation Right-Handed

Neck Pickup Rout **Gibson Mini Hum**

Middle Pickup **Gibson Mini Hum**

Bridge Pickup **Gibson Mini Hum**

Bridge Cut Non-Jazzmaster® Tremolo or Hardtail Bridge

Controls Volume 1, Tone 1, Input Jack

Upper Switch Upper Blade Switch

Lower Switch None

Hardware and electronics from Warmoth

Neck Screws Color Stainless-Steel

Pickguard Screws Color Stainless-Steel

1/4" Jack, Mono

Football Side-Jack Plate Color Chrome

Flat-Top Knob Color Chrome x2

500K Audio Pot x2

Guitar String Ferrule x6 Color Chrome

Schaller S-Locks Color Chrome

Parts to be ordered non-Warmoth

Tuners: Hipshot Staggered Locking Tuners with UMP plate chrome ... x

Buttons: Hipshot Hex Pearloid .... x

Bridge: Callaham Am. Std Hardtail w/ 3 enhanced compensated brass saddles X

Custom Neck Plate with pad ............... X

PUPS: DiMarzio Minihumbuckers DP 240x2 + DP241 .. X

tone control: .022 mfd cap ..let the tech source it ................................X

Treble Bleed on volume: something ... let tech choose and source, 180pf?.......X

Toggle: Freeway 10 position. ...x

Miniswitch On/on 3dpt ....x

Dress nut for miniswitch ... x

Miniswitch tip: white. ..... x

Case: Unknown at this point, probably gator

Strap: Sun Strap Red

Stings: D'Addario Nickel 10's .....x

It took 50 days of planning to get to this point. Now it's execution!

Warhead Guitar Neck

Construction Modern

Shaft Wood Quartersawn Maple

Fretboard Wood Indian Rosewood

Nut Width 1-3/4" (44mm) - Wide

Right / Left Handed Right-Handed

Neck Back Profile Wolfgang

Fretboard Radius 10" - 16" Compound

Number of Frets 21

Scallops None

Binding None

Fret Size & Material SS6150 - Wide & Tall (Stainless)

Tuner Hole Size Schaller/Modern Fender/Sperzel (25/64")

Inlay Shape Split Diamond

Inlay Material White Pearloid

Side Dots White Side Dots

String Nut Standard Nut - GraphTech White TUSQ XL

Mounting Holes Standard 4-Bolt

Neck Heel Shape Strat® Shape

Finish Vintage Tint Gloss

Jazzmaster® Replacement Guitar Body

Construction Chambered

Core Wood **Extra Light Poplar**

Lam Top Wood Alder

Right / Left Handed Right-Handed

Control Cavity Top Rout

Neck Pickup Rout Humbucker

Middle Pickup Rout Humbucker

Bridge Pickup Rout Humbucker

F-Holes None

Jack Rout 7/8" (22mm) Side Jack Hole

Bridge Rout Type Hardtail

Bridge Rout Fender American Standard Strat® Flat Mount

Mounting Holes Standard 4-Bolt

Neck Pocket Shape Strat®

Body Contours Forearm Contour, Tummy Cut

Binding and Edge Decorations Pearloid Binding (Drop Top)

Battery Box None

Paint Category Flake

Inferno Flake

Gloss

Jazzmaster® Pickguard

Color / Material White Pearl

Right / Left Orientation Right-Handed

Neck Pickup Rout **Gibson Mini Hum**

Middle Pickup **Gibson Mini Hum**

Bridge Pickup **Gibson Mini Hum**

Bridge Cut Non-Jazzmaster® Tremolo or Hardtail Bridge

Controls Volume 1, Tone 1, Input Jack

Upper Switch Upper Blade Switch

Lower Switch None

Hardware and electronics from Warmoth

Neck Screws Color Stainless-Steel

Pickguard Screws Color Stainless-Steel

1/4" Jack, Mono

Football Side-Jack Plate Color Chrome

Flat-Top Knob Color Chrome x2

500K Audio Pot x2

Guitar String Ferrule x6 Color Chrome

Schaller S-Locks Color Chrome

Parts to be ordered non-Warmoth

Tuners: Hipshot Staggered Locking Tuners with UMP plate chrome ... x

Buttons: Hipshot Hex Pearloid .... x

Bridge: Callaham Am. Std Hardtail w/ 3 enhanced compensated brass saddles X

Custom Neck Plate with pad ............... X

PUPS: DiMarzio Minihumbuckers DP 240x2 + DP241 .. X

tone control: .022 mfd cap ..let the tech source it ................................X

Treble Bleed on volume: something ... let tech choose and source, 180pf?.......X

Toggle: Freeway 10 position. ...x

Miniswitch On/on 3dpt ....x

Dress nut for miniswitch ... x

Miniswitch tip: white. ..... x

Case: Unknown at this point, probably gator

Strap: Sun Strap Red

Stings: D'Addario Nickel 10's .....x

Last edited:

Rick

Epic Member

- Messages

- 7,150

The thing that will probably take the longest to do is the body. Let's say it gets into the system today, July 17, then I imagine that this week a big drawer gets opened called Rick's order. I'll call that week 1.

I imagine that there's a check list on the front of the drawer. Each week they check something off.

The next week the extra light body blank gets pulled out of pile, I imagine there're about 10 - 20 blanks, and they pick the lightest one that day, put in the drawer, call that week 2

Then the CNC machine, first round, mostly chambering, call that week 3

Then the the lam top gets picked, call that week 4

Then the lam top gets glued, call that week 5

Then the body gets a second round of CNC, week 6

Then the binding gets applied, week 7

Then the body gets sanded, week 8

Then quality control review, week 9

Then to the paint room, week 10

Then three coats of paint, undercoat week 11

flake coat (maybe two coats) week 12

clear coat (maybe three coats) week 13,

let it dry a week, and QC 14,

Buffing, week, and qc 15

Mailing week 16.

According to the website, 16 to 18 weeks. That seems about right, though I'm hoping it's sooner, so that's somewhere between November 6 and November 20. Phew. Well at least that gives me time to accumulate the non-warmoth sourced parts. I guess every week, I'll scan the internet for sales and discounts, and whatever's on sale I'll get, but I'll be buying something every week for 12 weeks, so that when the warmoth package comes, I'll assemble it in one weekend, though due to the freeway switch, the mini switch and having 20 different sounds, I'll probably bring the soldering to an expert so I don't mess it up.

I imagine that there's a check list on the front of the drawer. Each week they check something off.

The next week the extra light body blank gets pulled out of pile, I imagine there're about 10 - 20 blanks, and they pick the lightest one that day, put in the drawer, call that week 2

Then the CNC machine, first round, mostly chambering, call that week 3

Then the the lam top gets picked, call that week 4

Then the lam top gets glued, call that week 5

Then the body gets a second round of CNC, week 6

Then the binding gets applied, week 7

Then the body gets sanded, week 8

Then quality control review, week 9

Then to the paint room, week 10

Then three coats of paint, undercoat week 11

flake coat (maybe two coats) week 12

clear coat (maybe three coats) week 13,

let it dry a week, and QC 14,

Buffing, week, and qc 15

Mailing week 16.

According to the website, 16 to 18 weeks. That seems about right, though I'm hoping it's sooner, so that's somewhere between November 6 and November 20. Phew. Well at least that gives me time to accumulate the non-warmoth sourced parts. I guess every week, I'll scan the internet for sales and discounts, and whatever's on sale I'll get, but I'll be buying something every week for 12 weeks, so that when the warmoth package comes, I'll assemble it in one weekend, though due to the freeway switch, the mini switch and having 20 different sounds, I'll probably bring the soldering to an expert so I don't mess it up.

Last edited:

Rick

Epic Member

- Messages

- 7,150

Paid the credit card bill. I feel like my metaphorical bin at the mothership is now ready to receive parts. Time to start the non-Warmoth part accumulation process. I guess I'll start with the pickups, being the most expensive. Or the least expensive, probably the 180pf treble bleed cap, or maybe a switch tip?

Rick

Epic Member

- Messages

- 7,150

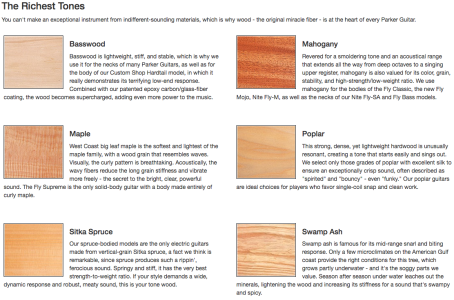

earlier there was a discussion on poplar, and I found this in y download files. Not sure what the marketing spoo of silk means but parker likes it because it sings. After i make the guitar ill report what silk means. Though i take the spoo in its entirety to mean bright, resonant with rounded tones. Edit:

Silk means the medullar rays present in some quatersawn wood. So guess the Poplar (tulip) wood Parker uses is 1/4 sawn. Or at least not completely flat.

Silk means the medullar rays present in some quatersawn wood. So guess the Poplar (tulip) wood Parker uses is 1/4 sawn. Or at least not completely flat.

Last edited:

VanHeGen

Senior Member

- Messages

- 357

Exciting! And a long wait….

One of my learnings from ordering my first Warmoth guitar was that I should at least have sourced the electronics from one reseller (like Thomann) and save on shipping costs, as they could probably have sourced the parts even if they didn’t have them. But more savings could definitely have been made by checking sales/discounts, as there is plenty of time to order the elctronics. And even more if I wouldn’t have ordered anything from the US (to Europe), as the shipping, taxes and customs costs become huge.

One of my learnings from ordering my first Warmoth guitar was that I should at least have sourced the electronics from one reseller (like Thomann) and save on shipping costs, as they could probably have sourced the parts even if they didn’t have them. But more savings could definitely have been made by checking sales/discounts, as there is plenty of time to order the elctronics. And even more if I wouldn’t have ordered anything from the US (to Europe), as the shipping, taxes and customs costs become huge.

Rick

Epic Member

- Messages

- 7,150

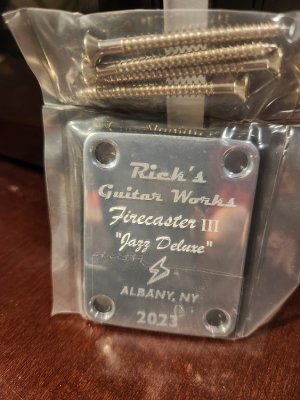

Ordered the custom neck plate! It'll look like this but will be a Firecaster, Jazz Deluxe made in 2023. Chome not gold and made in my hometown. The name acknowledge s that its inspired by a firebird and a jazzmaster . Firemaster didn't sound right nor did jazzbird. Pics when it arrives. Instead of a sun it'll have a bolt of electricity. The DP241 is reputed to be a good jazz pickup, and the DP 240 is great for country, folk  and rock, sort of like a tele neck pickup, but warmer and stronger.

and rock, sort of like a tele neck pickup, but warmer and stronger.

and rock, sort of like a tele neck pickup, but warmer and stronger.

and rock, sort of like a tele neck pickup, but warmer and stronger.

Last edited:

TBurst Std

Hero Member

- Messages

- 3,659

You cannot go wrong with Callaham parts

supertruper1988

Senior Member

- Messages

- 702

I must have missed it what headstock did you go with?

Similar threads

- Replies

- 8

- Views

- 5K

- Replies

- 11

- Views

- 3K