You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

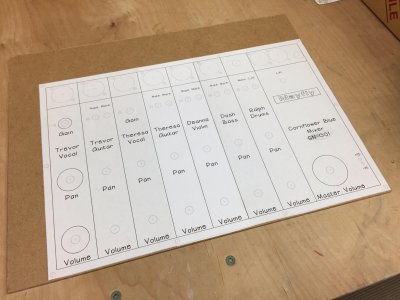

Building my own live mixer

- Thread starter mayfly

- Start date

mayfly

Epic Member

- Messages

- 9,204

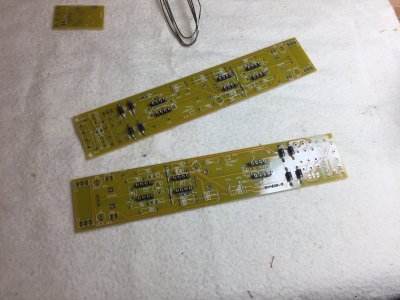

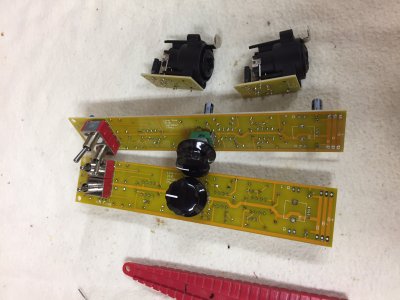

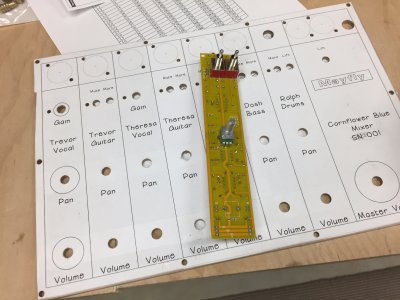

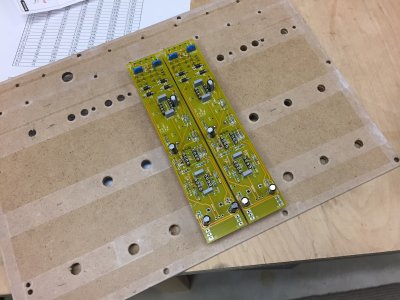

Putting together another couple of line / instrument preamps. I'm quite impressed with this circuit; it can handle instrument levels with no loss of tone all the way up to line level. There appears to be a very high input impedance which suits the instruments and it has enough headroom to easily accommodate a +4db balanced signal. I'm really pleased with it.

Attachments

mayfly

Epic Member

- Messages

- 9,204

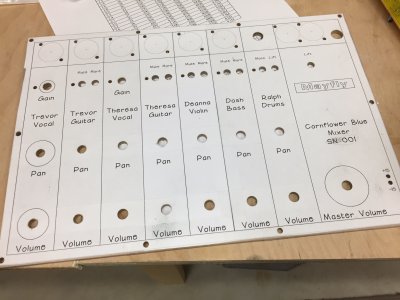

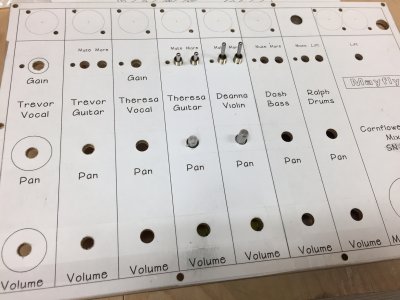

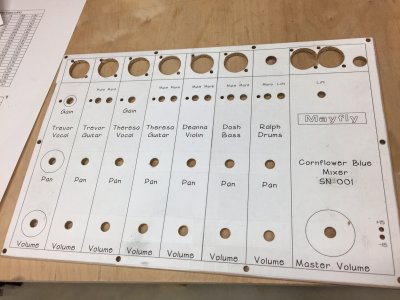

More stuff. Got around to drilling out the mockup top plate. I used brad point bits and it went very well - a nice clean hole through the paper and out the back.

For at least the line / instrument preamps, everything lined up well. Will check the others later. However - the switch holes were a little tight - might go up a bit in size in the final version.

Looks good from the back as well.

For at least the line / instrument preamps, everything lined up well. Will check the others later. However - the switch holes were a little tight - might go up a bit in size in the final version.

Looks good from the back as well.

Attachments

Cagey

Mythical Status

- Messages

- 24,425

You were right to design your own. I've Googled the hell out of mixers in all sorts of configurations from every manufacturer extant, and I can't find any that have "Trevor Guitar" or "Deanna Violin" inputs. At best, they give you channel numbers and maybe a little blank spot you can scribble on.

mayfly

Epic Member

- Messages

- 9,204

Thanks Cagey!

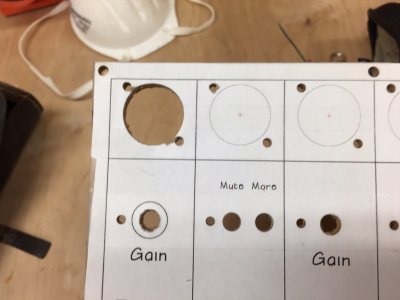

For my next trick, I'm going to drill out those big holes along the top that are for the XLR connectors. But there's a problem: I don't have a brad point bit that big.

So I rummaged around and found my Greenlee knockout punch! This relic from my Tube Amp days is for putting big ass holes in steel. We're gonna find out how it works on particle board!!

For my next trick, I'm going to drill out those big holes along the top that are for the XLR connectors. But there's a problem: I don't have a brad point bit that big.

So I rummaged around and found my Greenlee knockout punch! This relic from my Tube Amp days is for putting big ass holes in steel. We're gonna find out how it works on particle board!!

Attachments

mayfly

Epic Member

- Messages

- 9,204

It is not! It is the case for a steel hole punch used by tradespeople around the world. After a working life with an electrician, this punch was gifted to me and subsequently used to punch many many tube amp chassis (before I got smart and started having them made to my specifications). It's a h*ll of a tool.

mayfly

Epic Member

- Messages

- 9,204

so before I started punching, I had a look at the die of the size I wanted to use. It was pretty beat up and rather dull. I decided to whip out the straight cut file and sharpen it up a bit. Glad that I did! It cut a fairly clean hole, well relatively speaking, which to be honest really surprised me

Attachments

Cagey

Mythical Status

- Messages

- 24,425

Mayfly said:It's a h*ll of a tool.

They also ain't cheap. I used to have one. That was a helluva gift.

mayfly

Epic Member

- Messages

- 9,204

Cagey said:Mayfly said:It's a h*ll of a tool.

They also ain't cheap. I used to have one. That was a helluva gift.

That got me wondering how much this little punch is worth, so I checked out eBay on used greenlees. Turns out $30 is about the norm for this punch set second hand

oh - and greenlee does not even make this exact set with the leather case anymore! I now own a vintage punch set :icon_jokercolor:

BigSteve22

Hero Member

- Messages

- 2,798

Oooooooooo, vintage........ Greenlee punches are the best panel punches, but I'd bet the vintage set is even better! So jealous.......... :confused4:

mayfly

Epic Member

- Messages

- 9,204

Here's everything (well, almost) bolted to the mock-up top panel. Still waiting on the PCBs for the stereo input and the new design of the summing mixer / power supply.

I've got the prototype summing mixer in there now complete with crazy-assed heatsinks. Here's how it looks from the bottom. It passed the smoke test and the regulators didn't overheat. More when I have some time to actually play through it

I've got the prototype summing mixer in there now complete with crazy-assed heatsinks. Here's how it looks from the bottom. It passed the smoke test and the regulators didn't overheat. More when I have some time to actually play through it

Attachments

Similar threads

- Replies

- 7

- Views

- 585

- Replies

- 4

- Views

- 327

- Replies

- 0

- Views

- 395

- Replies

- 13

- Views

- 811