mayfly

Epic Member

- Messages

- 9,085

Hi folks,

Because of my never ending quest for excellence, and also because I'm completely insane, I've decided to try my hand at building my own live music mixer, specifically designed for my band Cornflower Blue. Yep, instead of being happy with a $100 mixer from Behringer, I thought I could do better.

So I set about thinking what the ideal mixer would look like. I figured it would have to be small, only include the channels I actually needed, be in it's own road case, and have excellent sound quality.

When it came to features, I departed pretty early from conventional wisdom! EQ? Who the hell needs that! A bunch of knobs that I'll always need to make sure are never on! If you don't have good tone at the source, fix it! Maybe a 80Hz low cut on mic inputs, but that's it! Speaking of mic inputs, when was the last time you used a condenser mic live??? Forget the phantom power! Who needs it!! Now compression on the mics - that's something that I would use! It would be great to have an instrument input that I could actually plug a violin directly into and not have it crap out. 10K input? 100K? forget it! I need at least 1M into a FET Style front end for that. A stereo input for electric drums and an iPod. A couple of line level inputs for guitars, but with mute switches for when Theresa leans her guitar against a monitor and wonders why it's feeding back. Oh - and it has to look cool. And be small. and drive line level into long cables. and ... and...

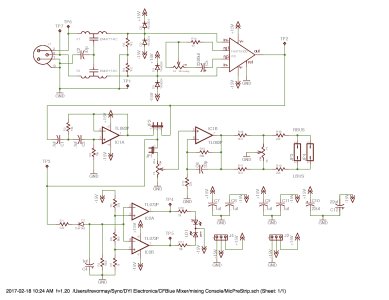

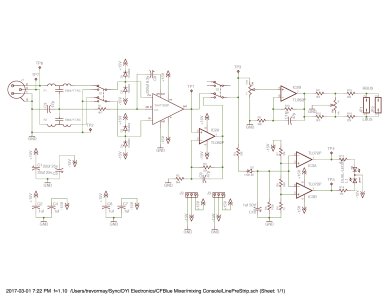

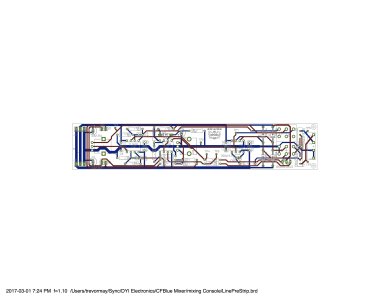

All this led me into a fairly long design phase. I did my research, did some test circuits, fired up good old Eagle Cad, layed out some boards, and sent them to dirty PCB for fabing just after Chinese new year. I just got them back today:

The blue boards are mic pre strips, the yellow ones are line level input strips, and the black ones are compressor side chains for the mic pres. More to come on the actual designs, the build, and how things sound.

Because of my never ending quest for excellence, and also because I'm completely insane, I've decided to try my hand at building my own live music mixer, specifically designed for my band Cornflower Blue. Yep, instead of being happy with a $100 mixer from Behringer, I thought I could do better.

So I set about thinking what the ideal mixer would look like. I figured it would have to be small, only include the channels I actually needed, be in it's own road case, and have excellent sound quality.

When it came to features, I departed pretty early from conventional wisdom! EQ? Who the hell needs that! A bunch of knobs that I'll always need to make sure are never on! If you don't have good tone at the source, fix it! Maybe a 80Hz low cut on mic inputs, but that's it! Speaking of mic inputs, when was the last time you used a condenser mic live??? Forget the phantom power! Who needs it!! Now compression on the mics - that's something that I would use! It would be great to have an instrument input that I could actually plug a violin directly into and not have it crap out. 10K input? 100K? forget it! I need at least 1M into a FET Style front end for that. A stereo input for electric drums and an iPod. A couple of line level inputs for guitars, but with mute switches for when Theresa leans her guitar against a monitor and wonders why it's feeding back. Oh - and it has to look cool. And be small. and drive line level into long cables. and ... and...

All this led me into a fairly long design phase. I did my research, did some test circuits, fired up good old Eagle Cad, layed out some boards, and sent them to dirty PCB for fabing just after Chinese new year. I just got them back today:

The blue boards are mic pre strips, the yellow ones are line level input strips, and the black ones are compressor side chains for the mic pres. More to come on the actual designs, the build, and how things sound.