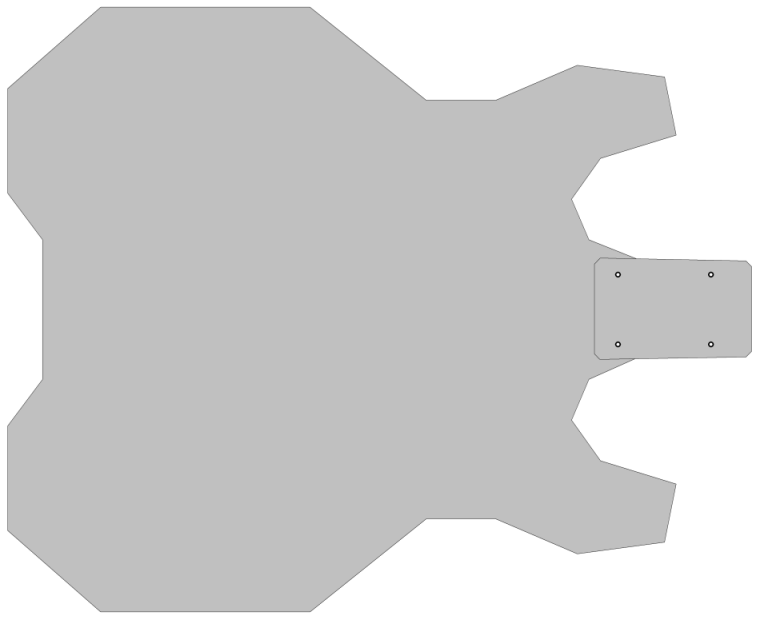

Hi everyone. Well, I've decided to try my hand at shaping my own symmetrical body out of a Warmoth routed body blank. The first guitar I ever bought new was a 1981 Vantage VS696. I was about 18-19 then and basically played the frets off it over the years. Finally gave up the ghost around Y2K, my brother damaged it beyond repair. Anyway, I came to really love that body shape (similar to the current Ibanez AX or 80s Carvin DC150 series). Warmoth and other body suppliers don't offer that body shape though, and I want a Floyd on it, so my only real option is to try to make one.

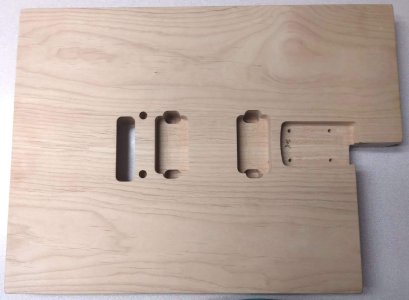

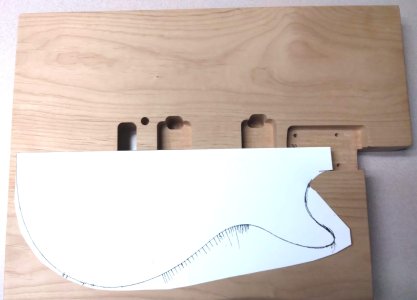

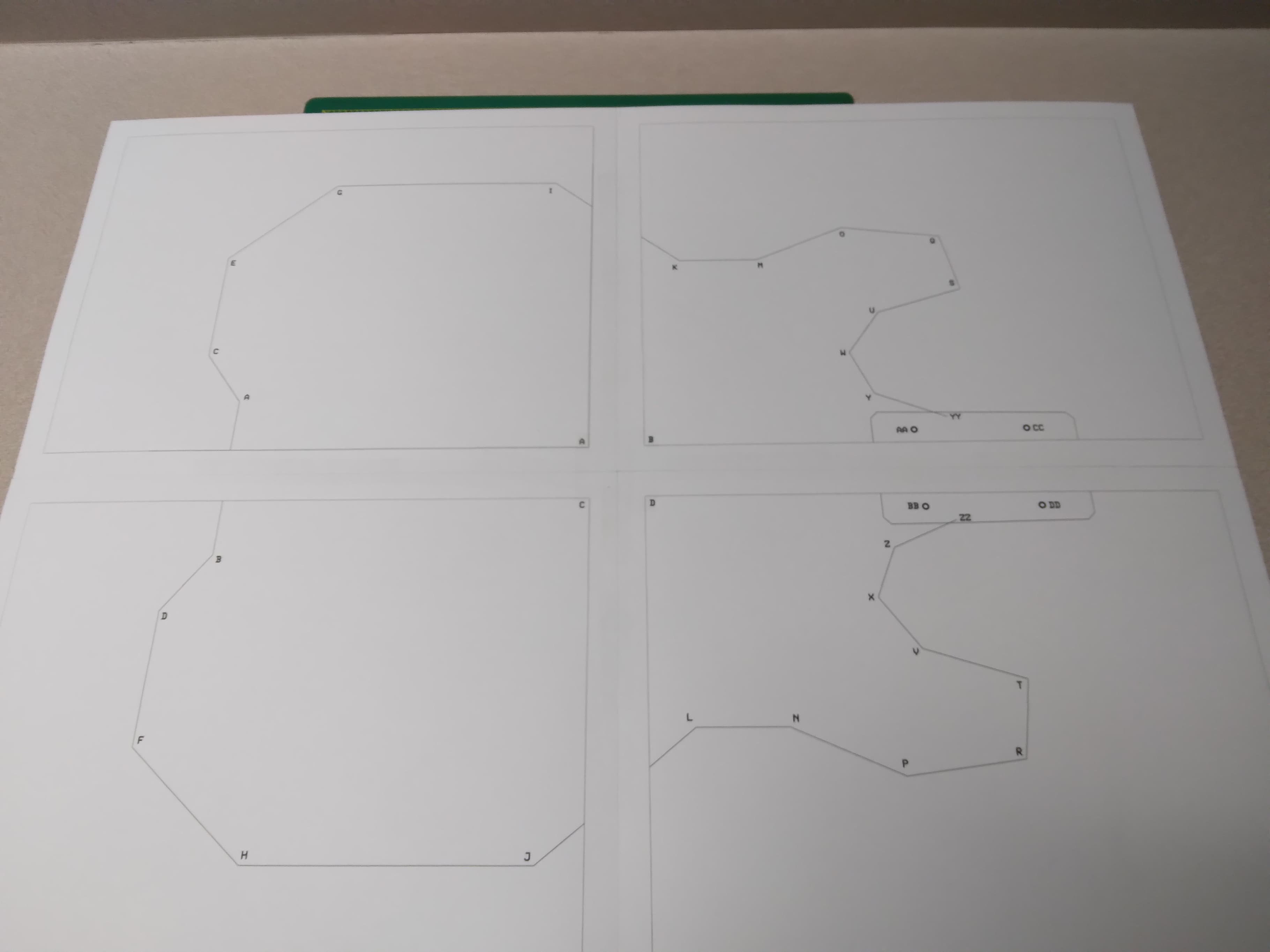

I ordered and recently received a routed body blank from Warmoth. I do have an 80s Carvin DC160 and traced that body onto some paper. It's not a perfect tracing but it doesn't need to be either, I'm not trying to make an exact copy anyway. I'll be making some minor changes to it but it is the basic style I'm looking for.

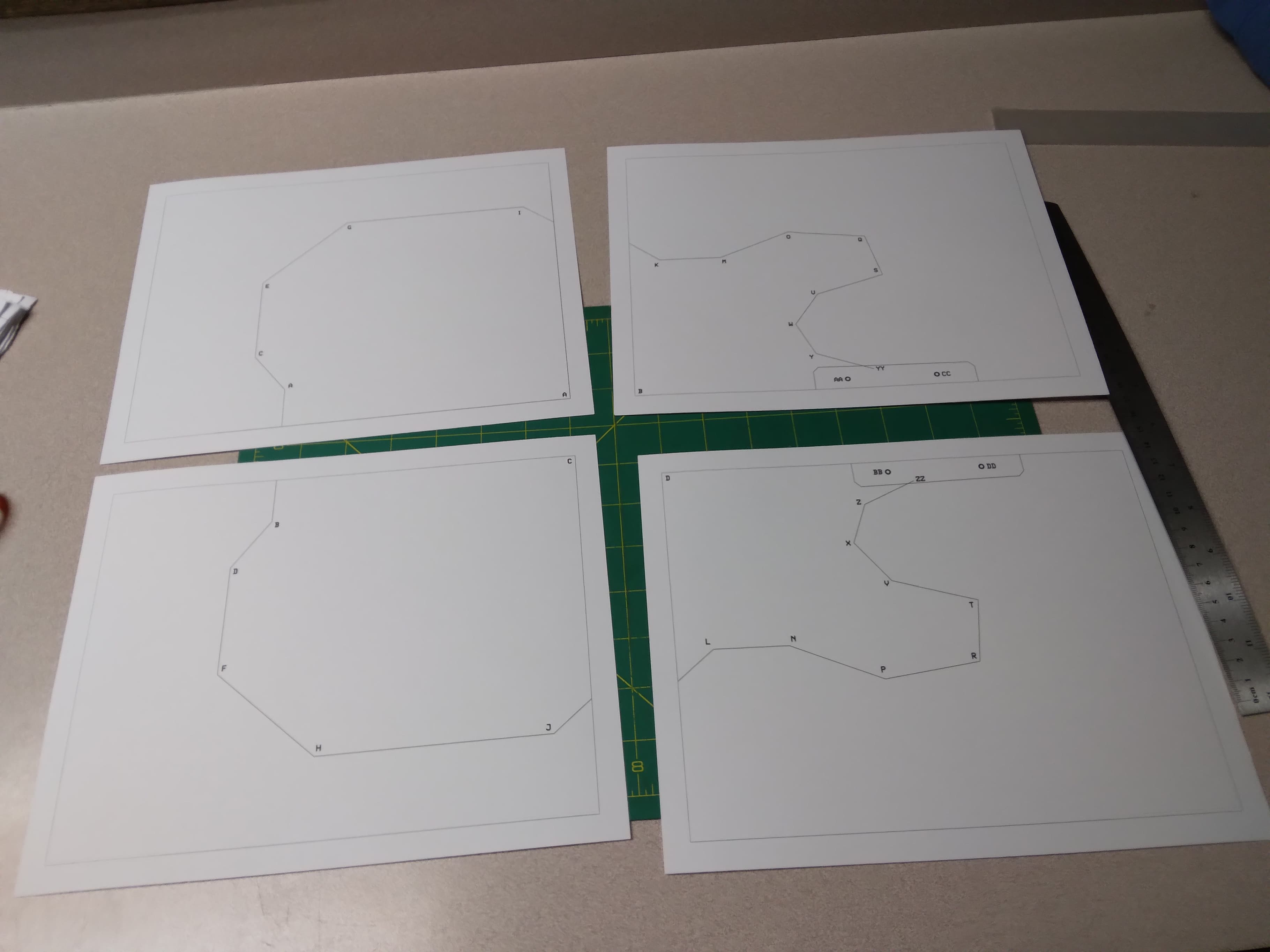

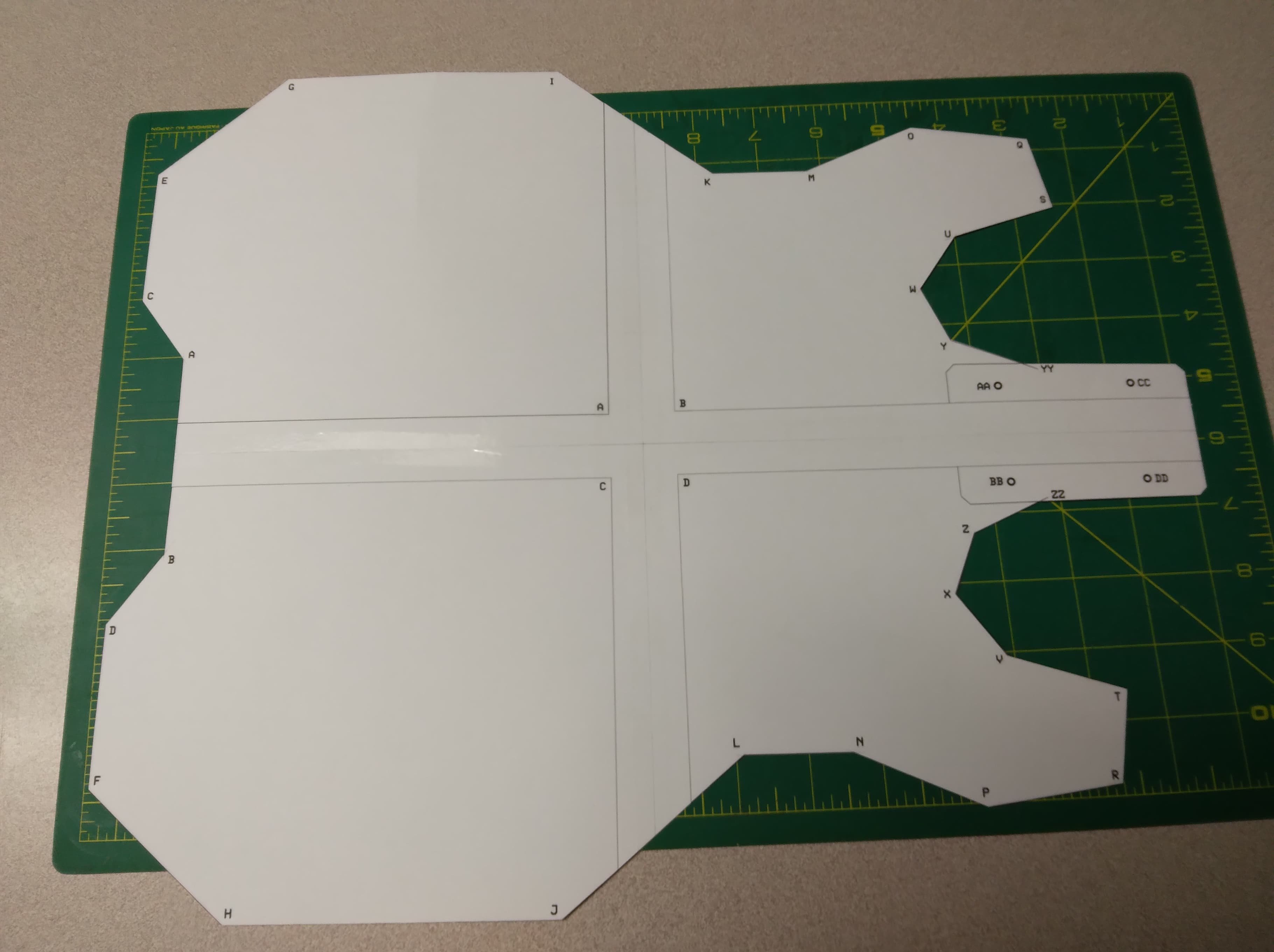

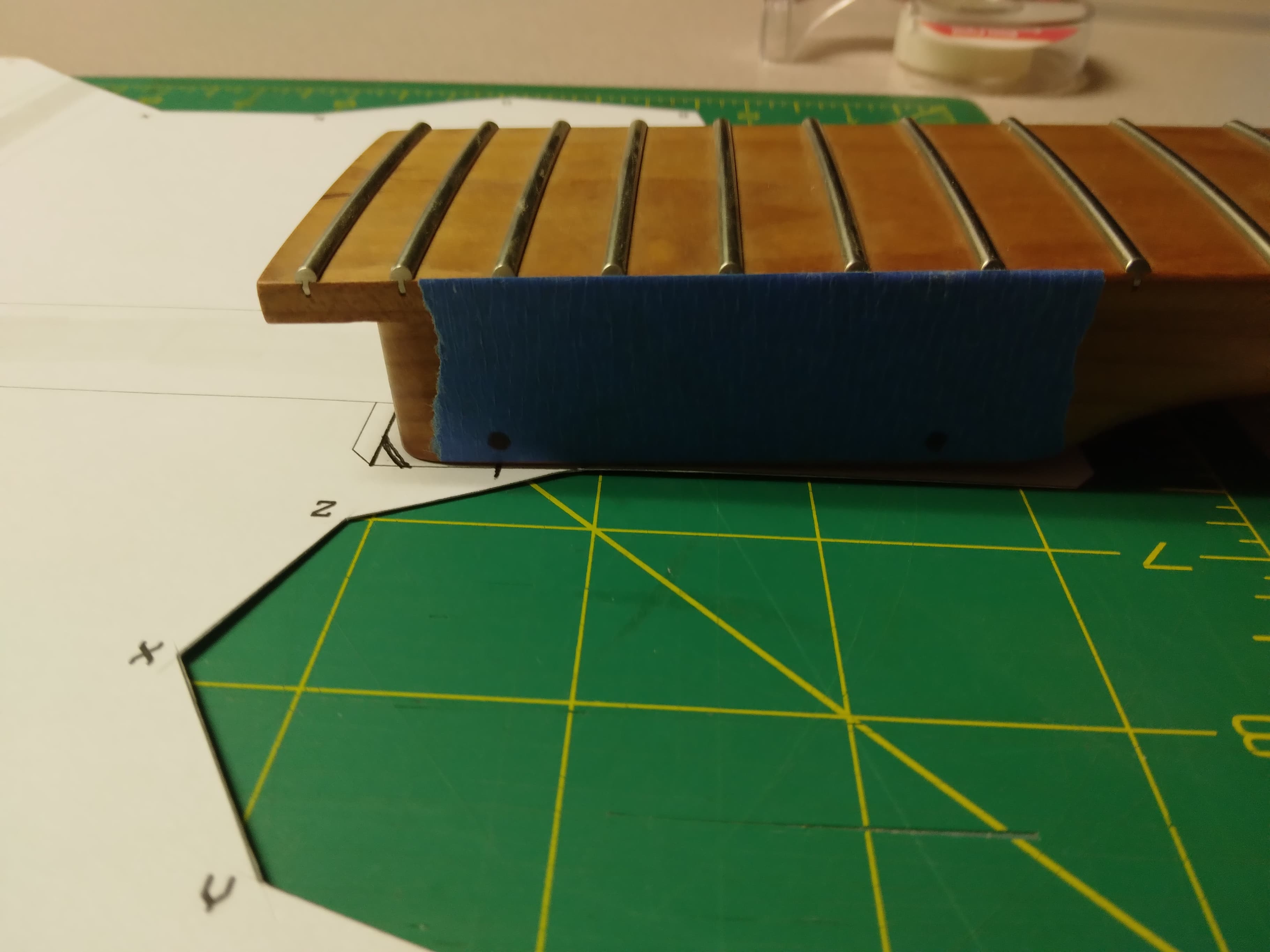

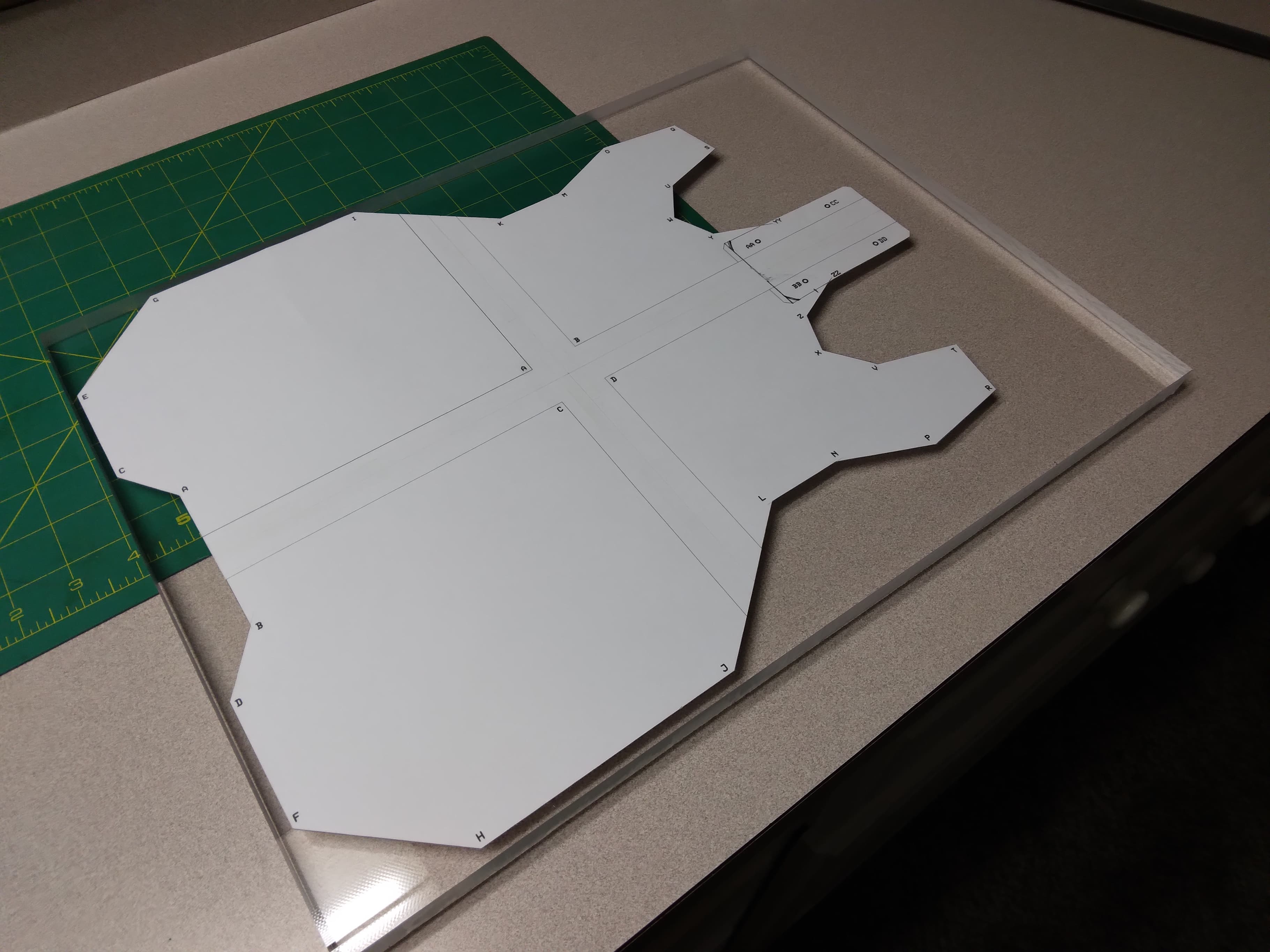

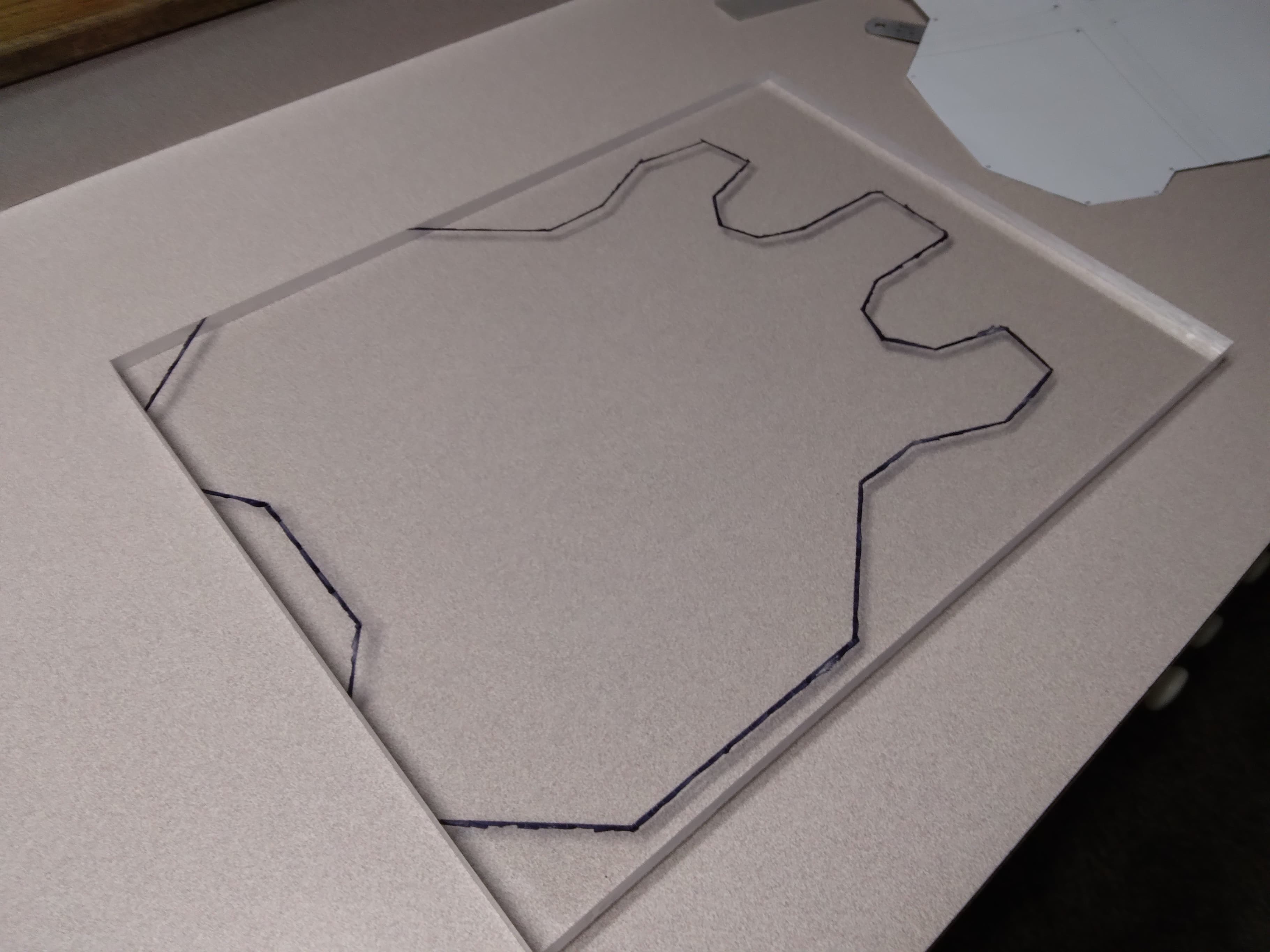

Since I've never cut a body shape before, this was my thinking. In order to create a body template and make sure it correctly fits the Warmoth neck I have on order (I have another Warmoth neck now that I can use to be sure), I thought it would be best to transfer the tracing onto a 0.1" thick acrylic sheet I can actually see through so I can adjust whatever is needed to be certain the template will be correct for the neck and lined up properly to the centerline by putting the acrylic tracing over top of the body and easily see the neck rout, etc. I will then cut out and sand the acrylic tracing carefully and use that as a template to make a 3/4" thick wood template for use to rout the body blank. I just want to be sure the template used to rout the body blank will be as correct as I can get for the neck pocket.

I've done some pattern shaping before with other projects including some pickguards and cavity covers along with other non-guitar projects so I'm quite familiar with that but have never done one as thick as a guitar body. I do have a small-ish router table I'll be using and will use several shallow passes to prevent problems as much as possible. I don't have a band saw though, so once I get the wood template made and transferred to the body blank I figured I'd use my drill press to drill a series of holes around the pattern to remove the excess wood and my spindle sander to smooth out the nubs and get somewhat close to the pattern so routing doesn't need to remove that much material.

If anyone has any tips in that area I'd be glad to read them! I'll try to take some photos as I go so you can see the progress.

Thank for reading!

I ordered and recently received a routed body blank from Warmoth. I do have an 80s Carvin DC160 and traced that body onto some paper. It's not a perfect tracing but it doesn't need to be either, I'm not trying to make an exact copy anyway. I'll be making some minor changes to it but it is the basic style I'm looking for.

Since I've never cut a body shape before, this was my thinking. In order to create a body template and make sure it correctly fits the Warmoth neck I have on order (I have another Warmoth neck now that I can use to be sure), I thought it would be best to transfer the tracing onto a 0.1" thick acrylic sheet I can actually see through so I can adjust whatever is needed to be certain the template will be correct for the neck and lined up properly to the centerline by putting the acrylic tracing over top of the body and easily see the neck rout, etc. I will then cut out and sand the acrylic tracing carefully and use that as a template to make a 3/4" thick wood template for use to rout the body blank. I just want to be sure the template used to rout the body blank will be as correct as I can get for the neck pocket.

I've done some pattern shaping before with other projects including some pickguards and cavity covers along with other non-guitar projects so I'm quite familiar with that but have never done one as thick as a guitar body. I do have a small-ish router table I'll be using and will use several shallow passes to prevent problems as much as possible. I don't have a band saw though, so once I get the wood template made and transferred to the body blank I figured I'd use my drill press to drill a series of holes around the pattern to remove the excess wood and my spindle sander to smooth out the nubs and get somewhat close to the pattern so routing doesn't need to remove that much material.

If anyone has any tips in that area I'd be glad to read them! I'll try to take some photos as I go so you can see the progress.

Thank for reading!