H108P

Junior Member

- Messages

- 28

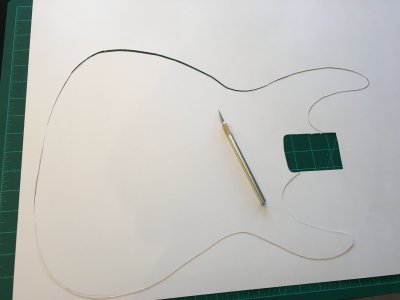

I just got this roasted swamp ash body blank and am excited to turn it into a guitar. After my roasted Soloist project, I felt that I was ready to move on to cutting out my own body shape.

I didn't get too weird with the body shape, I still prefer a super Strat format - I've been playing a Strat or Soloist type guitar forever - but I had a few ideas I wanted to try. I transferred my sketch from my pad onto a piece of poster board and marked the center line on both sides. I also marked the center line on the slab, on both sides.

Using the neck pocket and the center lines on both sides of the slab and stencil, I traced the outline onto the blank.

Can't wait to make this into a guitar shape!

I didn't get too weird with the body shape, I still prefer a super Strat format - I've been playing a Strat or Soloist type guitar forever - but I had a few ideas I wanted to try. I transferred my sketch from my pad onto a piece of poster board and marked the center line on both sides. I also marked the center line on the slab, on both sides.

Using the neck pocket and the center lines on both sides of the slab and stencil, I traced the outline onto the blank.

Can't wait to make this into a guitar shape!