mycroftxxx

Junior Member

- Messages

- 83

In retrospect, yeah, that’s what I should have done, but I didn’t have the scrap woodFor that type of drilling, place a block of scrap wood at the back of the part to be drilled out. That way the drill does not go into thin air.

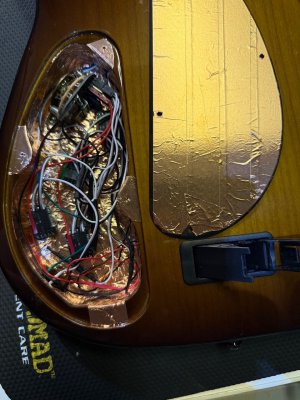

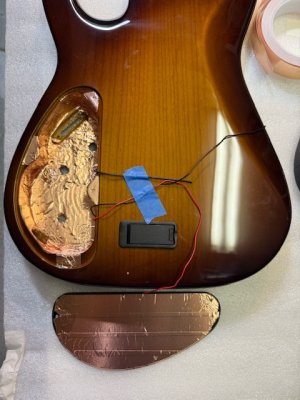

Anyway, highlights of today so far: got the battery box installed, and copper tape applied to the electronics cavity and its cover:

The battery box was a mild PITA: I didn’t sand the finish in the battery box compartment, so the whole thing fits kind of tight. I ended up doing a mild sanding of the tabs that lock the battery container part closed, and that got rid of just enough friction to let me open the battery compartment without needing tools to pry it open

Next, I test fit the neck, bridge, and pickup rings:

(Yes, I overlooked that bit of tape on the upper right corner of the bridge and had to fix it later

When I was doing a rough measurement of string height with a hand-tight 1st and 6th strings installed, I really had to jack up the bridge elements, so much so that I was afraid I’d run out of adjustment room, so I installed the Schaller spacer for this bridge:

I might have to redo this when I get the neck fully strung, but it looks promising for now.

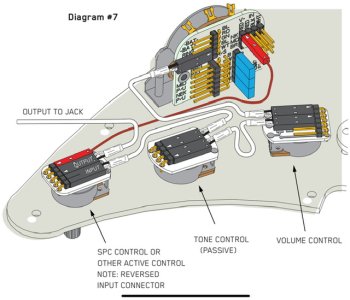

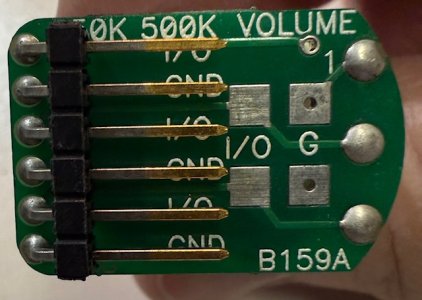

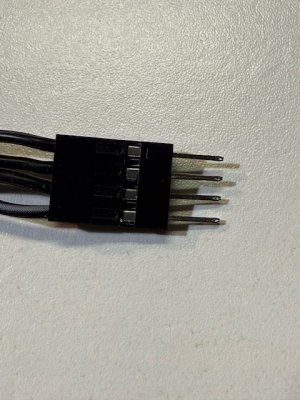

Next up: electronics hookup! Will at least start this tonight; I’ll see how far I get…