Going to replace the stock strat 2 post modern bridge with a 54mm vintage style.

Saw some vids that demo how to remove the inserts that anchored the 2posts into the body. Think I’ll be okay with that and plugging, etc.

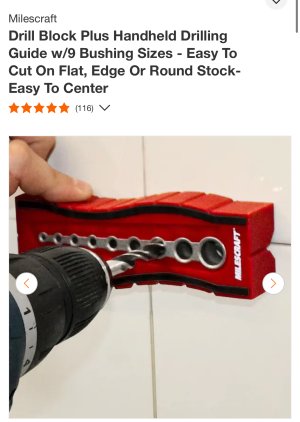

However, I’m wondering about drilling the pilot holes for the new bridge without a drill press. What can be used as a guide for the drill bit to keep it square to the body? Or should I just get a cheap drill press and return it when done?

Saw a seemingly clever suggestion that recommended using the old tone block. The main challenge there is making sure I’ve got adequate control of the placement of the “jig” and also am careful about the depth of the pilot hole. Think once the locations were accurately marked. Make a small punch so that the correct positioning the drill bit through “jig” can be felt. But how could I monitor depth?

I guess a block of clear acrylic would work better as I could tape the bit to mark desired depth and see through the block to monitor it. But then if I make that jig there is still potential issue with creating it so it’s square to the body plane - and keeps it’s squareness while drilling each hole.

What do you suggest? Find a local wood shop that’ll do it?

Saw some vids that demo how to remove the inserts that anchored the 2posts into the body. Think I’ll be okay with that and plugging, etc.

However, I’m wondering about drilling the pilot holes for the new bridge without a drill press. What can be used as a guide for the drill bit to keep it square to the body? Or should I just get a cheap drill press and return it when done?

Saw a seemingly clever suggestion that recommended using the old tone block. The main challenge there is making sure I’ve got adequate control of the placement of the “jig” and also am careful about the depth of the pilot hole. Think once the locations were accurately marked. Make a small punch so that the correct positioning the drill bit through “jig” can be felt. But how could I monitor depth?

I guess a block of clear acrylic would work better as I could tape the bit to mark desired depth and see through the block to monitor it. But then if I make that jig there is still potential issue with creating it so it’s square to the body plane - and keeps it’s squareness while drilling each hole.

What do you suggest? Find a local wood shop that’ll do it?

Last edited: