I've been drinking green tea all day....and now you're gonna bring out the demon in me??!! :icon_biggrin:

You will never find a more ardent advocate for a comfortable contoured heel than me. I don't like feeling a sharp corner in the palm of my hand every time I go for the glory notes any more than you do.

But....

Here are a few of the factors Warmoth has to wrestle with:

1. Fender's vintage/original USA heel and neck pocket spec is the cornerstone of our business. How far do you dare stray from the thing thing that pays your rent and keeps the lights on?

2. Our products are complicated enough as it is. Us veterans may have no problem navigating the dizzying array of options, but first-timers are intimidated. How much more complicated can we make things before the amount of options is more harmful than helpful? Our options need to be simpler to understand, not harder. Our website needs to be simpler to order from, not harder.

3. We are a

parts company. We don't sell guitars or kits, we sell parts. As such, we need to have maximum compatibility.

4. Indeed, there are several precedents among the Warmoth line-up for proprietary development. 7/8 line. Short scale bass line. Bass6. 7-string. Couldn't a line of guitar bodies with contoured heels be among them? Yes, it could, but that would bring up a whole new set of problems. For example...what necks are you going to use with them? If change the bolt pattern, you can't use Modern Construction necks, because of the Side-Adjust Mechanism. If you do change the bolt pattern and only offer the Vintage/Modern necks, you can't get a Floyd Nut....which is going to be a commonly requested option for use with bodies with contoured heels. So do you have to develop a new neck to go along with these new bodies?

5. All of this requires a

considerable financial investment. People think this stuff is easy. It's not. It is never a slam-dunk. The recent development of the NFT Floyd Rose bridge rout was not easy. There were huge problems behind the scenes that almost no one knows about. Developing that option cost Warmoth a lot of money....that we still have not recouped in orders for it.

Want me to lay myself bare? OK...here is the raw truth: If I were the king of Warmoth, my short list of immediate new options to develop would be:

A. Rolled fretboard edges.

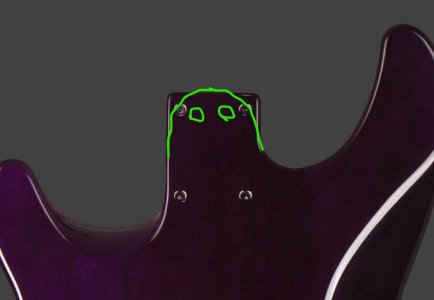

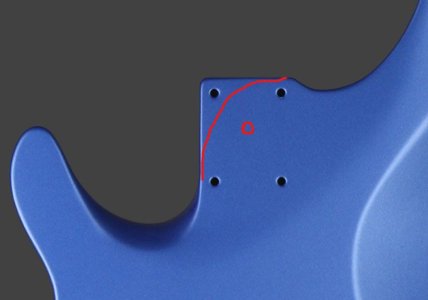

B. A true contoured heel design.

C. A new neck construction that features a traditional single truss-rod

and options for binding, Floyd nuts, etc.

Secondary new options would be:

D. A new neck construction with spoke-wheel truss rod (possibly the same new neck construction as #C above).

E. New, modern body designs, and a general move away from any designs over 50 years old. (dangerous....see #1 above.)

F. A broader selection of neck back profiles

F. A broader selection of less extreme compound radius fretboard options. (e.g. 9.5"-14")

I've voiced all these suggestions (many times). The execs have listened. They are actually very receptive to the input of the employees here. But they also have to weigh the cost of developing and implementing these things into a large-scale production environment against the potential financial return.

Making those decisions is hard. Once you decide, developing that products and options is hard. Figuring out how to integrate them into the current product process is hard, Then figuring out how to shoe-horn all the new stuff into an already overly-complicated website is hard. Trying to figure out how to market them in a way that even new customers can understand is hard.

To sum up: it's not that we don't want to. It's just all really,

really hard.

Don't get me wrong. I love my job.

But you asked.