jackthehack

Epic Member

- Messages

- 5,630

Well, here we are in DIY finishing phase; here was original concept:

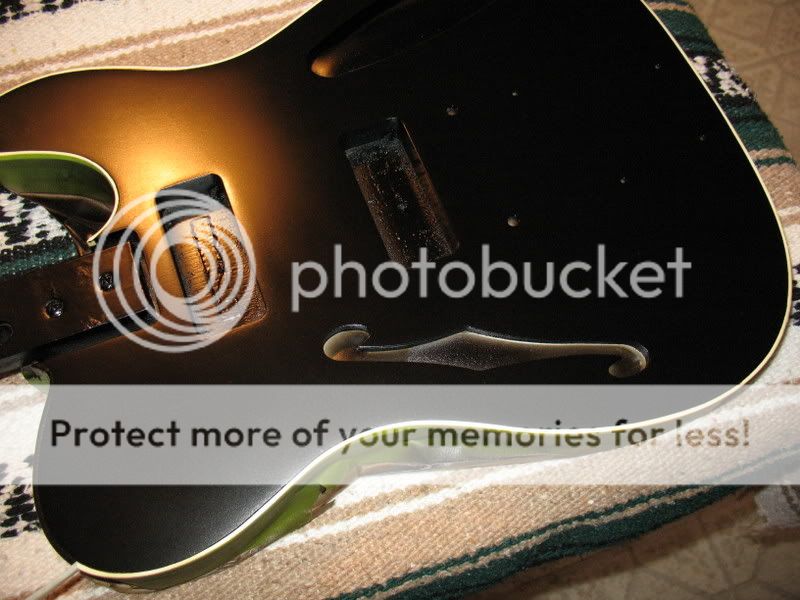

Here are the parts as arrived today:

One issue is that the mahogany coloration is way different between the neck and body (so much for the "try to match" plea in ordering instructions, so I don't know how feasible the idea of trying to replicate the original back color from a '54 Gibson will be, if you check this link with pics: http://www.provide.net/~cfh/lpgold0.html the original finish was a lot lighter brown than all the re-issues over the years and didn't have dark grain fill. Was going to grain fill brown and use one of the lighter shades of Tandy leather dye to try to match, but don't know that that's feasible; may wind up doing a black grain fill and a darker hue of brown on the back, or maybe wind up shoot with toner instead of dying it - I'm sure CB's got some opinion about that...

The other issue is masking the binding... no problem for grain filling and dying or shooting toner on the back, but anyone have any handy hints about masking the narrow lip around the top? Be a while before I get there, it's turning off cold so it'll probably take most of the week just to get the grain filled as drying times will be SLOW.....

Here are the parts as arrived today:

One issue is that the mahogany coloration is way different between the neck and body (so much for the "try to match" plea in ordering instructions, so I don't know how feasible the idea of trying to replicate the original back color from a '54 Gibson will be, if you check this link with pics: http://www.provide.net/~cfh/lpgold0.html the original finish was a lot lighter brown than all the re-issues over the years and didn't have dark grain fill. Was going to grain fill brown and use one of the lighter shades of Tandy leather dye to try to match, but don't know that that's feasible; may wind up doing a black grain fill and a darker hue of brown on the back, or maybe wind up shoot with toner instead of dying it - I'm sure CB's got some opinion about that...

The other issue is masking the binding... no problem for grain filling and dying or shooting toner on the back, but anyone have any handy hints about masking the narrow lip around the top? Be a while before I get there, it's turning off cold so it'll probably take most of the week just to get the grain filled as drying times will be SLOW.....