PhilHill

Hero Member

- Messages

- 1,653

Here we go again. The Wood Gnomes have been in my shop again. I don't like it because they never clean up after themselves. I put up with it because they always leave presents behind. This time it was two large slabs of Black Walnut, and some smaller ones of Zebrawood. The walnut and zebra seemed to get along well, so I glued them up into a body blank. We shall see what results...

.

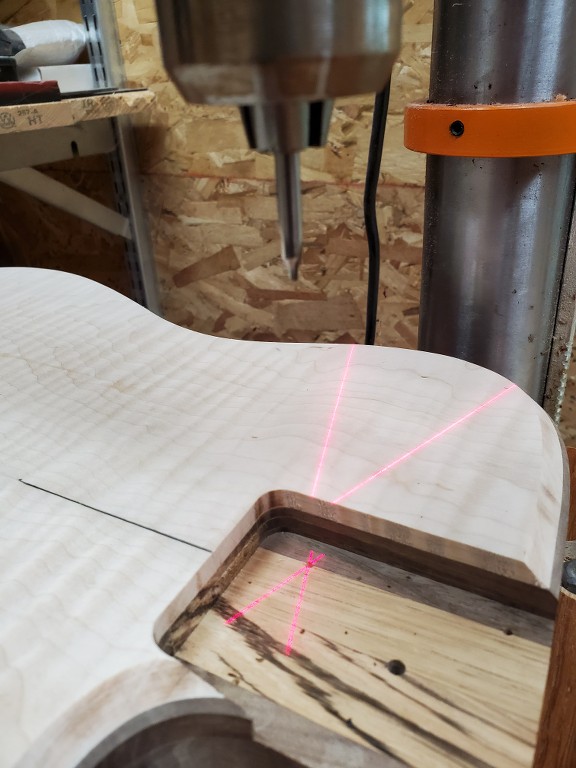

. I made a new template with a shape kinda like a small cutaway acoustic and traced it out on the blank. After bandsawing it out and doing a little smoothing on the spindle sander it seemed a little heavy. So we'll drill some pockets to lighten it up a little.

.

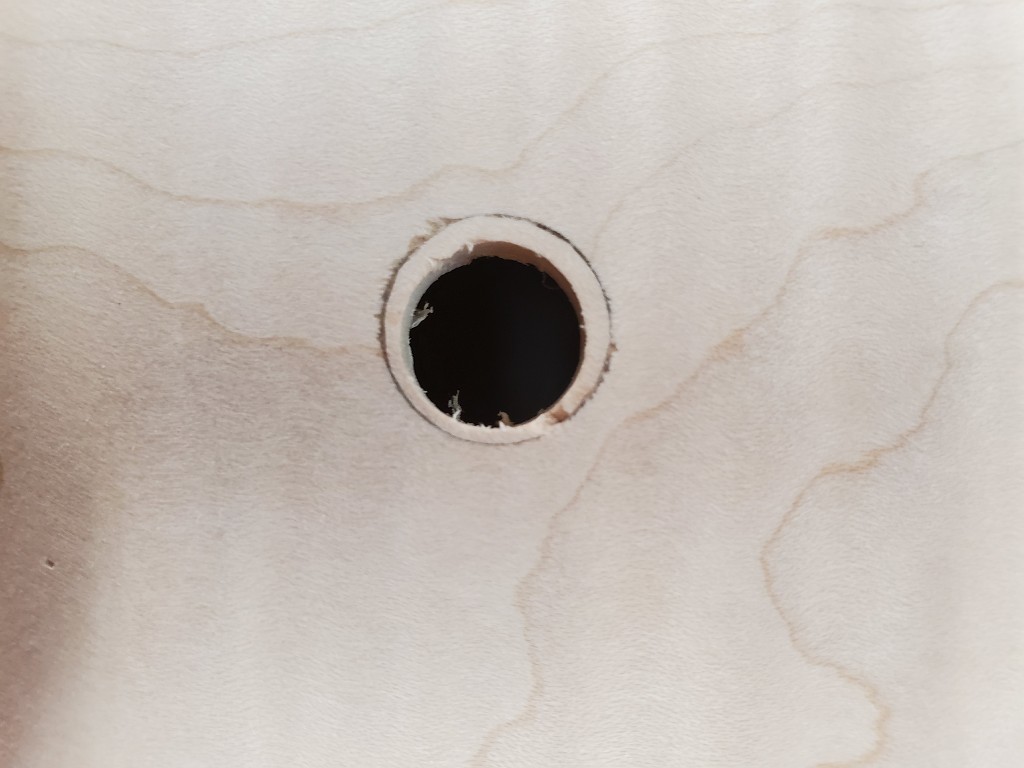

. Then of course you have to have a control cavity. Routed for a cover too.

.

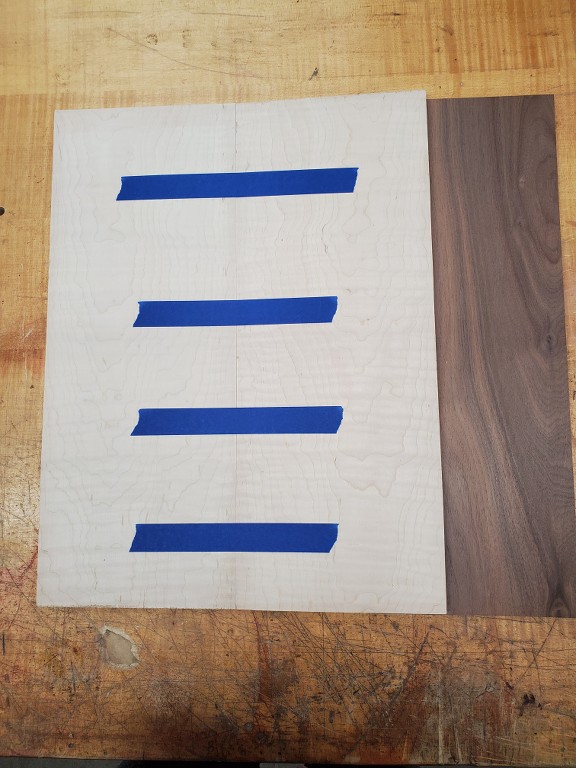

. Speaking of covers, I decided more Zebra would be good. The pieces were too narrow so I re-sawed some and book matched it. The band saw seemed a little overkill for this, so I went old school.

.

. And again, some spindle sanding and we're good I think.

.

. And on the other side, routed some channels from the pickup locations into the cavity so I don't have to drill holes later.

.

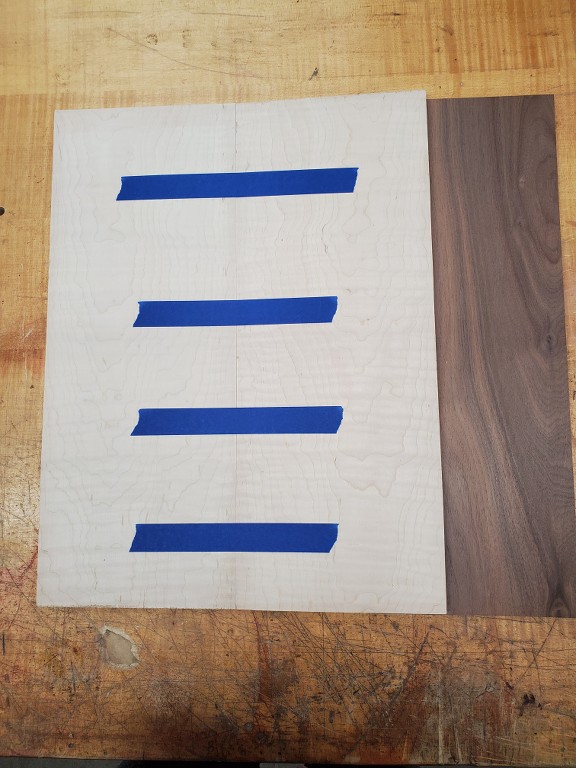

. Then we begin gluing up a top. Some curl maple should do nicely.

.

. A good trick when gluing up a book matched top is to place them together, tilt one side up a little and place strips of tape across the back. Then when you put glue on the edges and flatten it out, the tape holds it together tighter until you get the clamps on. It also helps to keep the two pieces evenly flat at the joint.

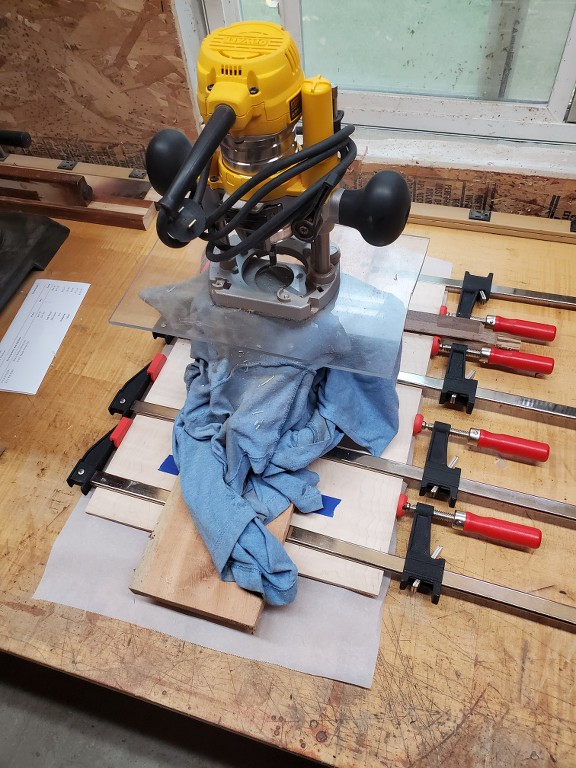

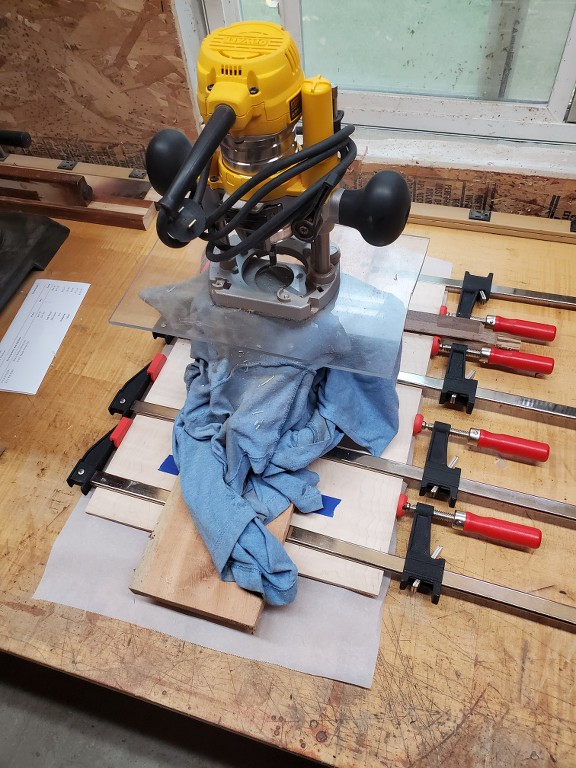

. Creative clamping.

.

. That's all for now...But "I'll be bock" as the Terminator once said............. :headbang:

.

. I made a new template with a shape kinda like a small cutaway acoustic and traced it out on the blank. After bandsawing it out and doing a little smoothing on the spindle sander it seemed a little heavy. So we'll drill some pockets to lighten it up a little.

.

. Then of course you have to have a control cavity. Routed for a cover too.

.

. Speaking of covers, I decided more Zebra would be good. The pieces were too narrow so I re-sawed some and book matched it. The band saw seemed a little overkill for this, so I went old school.

.

. And again, some spindle sanding and we're good I think.

.

. And on the other side, routed some channels from the pickup locations into the cavity so I don't have to drill holes later.

.

. Then we begin gluing up a top. Some curl maple should do nicely.

.

. A good trick when gluing up a book matched top is to place them together, tilt one side up a little and place strips of tape across the back. Then when you put glue on the edges and flatten it out, the tape holds it together tighter until you get the clamps on. It also helps to keep the two pieces evenly flat at the joint.

. Creative clamping.

.

. That's all for now...But "I'll be bock" as the Terminator once said............. :headbang: