Looks like a really good recovery job. The main thing is your 'learning experience' was achieved without personal injury!

I've been using routerbeasts to wreak carnage on various wooden things for 30+ years - in the last few of those I've even been attempting to do so 'properly', or at least in a way that works for me in terms of safety and satisfactory results. YMMV and all that, but a few thoughts...

Always use good quality, sharp, clean cutters.

I always use a router table when doing guitar perimeter cuts, because if something is going to be pulled out of my hands and thrown at me, I'd rather it was a few pounds of wood than a few pounds of machinery equipped with 20,000+ rpm razor-sharp tungsten carbide blades.

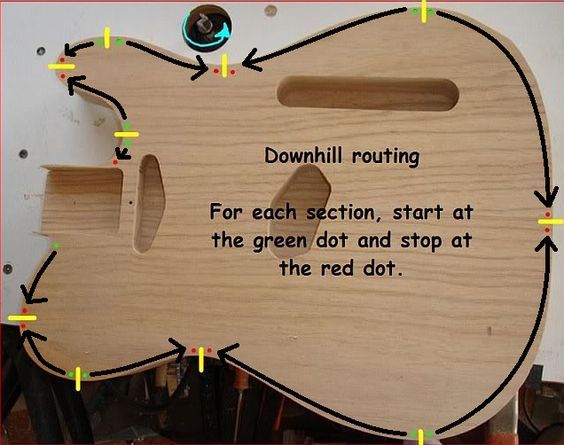

Regarding the uphill/downhill thing, here's another pic:

I always try to stick to this, but never route the 'wrong way', always moving the workpiece from right to left - I cut the full thickness of the body using a 50mm ~ 2" cutter with shank and end bearings which allows me to do the cuts shown as clockwise on the above pic with the template on top, then flip the body over to do the rest.

The only tear-out I've had has been due to mishandling the workpiece - inadvertently moving it the wrong way, allowing the router to do the dreaded 'grab'. (That tight little curve above the neck pocket on a Tele is a pig, but I do now have a fun double cutaway La Cabronita body to finish - necessity is the mother of invention etc.)

Also, I only use the router to remove a small amount of material - band saw to get it close, then sand closer - about 1.5mm ~ 1/16".

Lam tops normally have the grain going the same way as the body - you can only regard the grain direction as being parallel to edges of the plank it came from, not the apparent waviness within that. Nothing to stop you having a cross-grain top (or using a burl slice 'in the round') but in those non-standard cases you'd either still cut as per the pic, or do the back first and then glue and trim the top to that - for various reasons I don't recommend the latter.

When using the 'beast hand-held - for roundovers etc., I would always still move it the right way - anti-clockwise for outside cuts - because I think that tear-out is only a small risk if 'the rules' are followed, whereas moving it the wrong way is actively asking for grab.

TL;DR?

Be careful with the routerbeast!