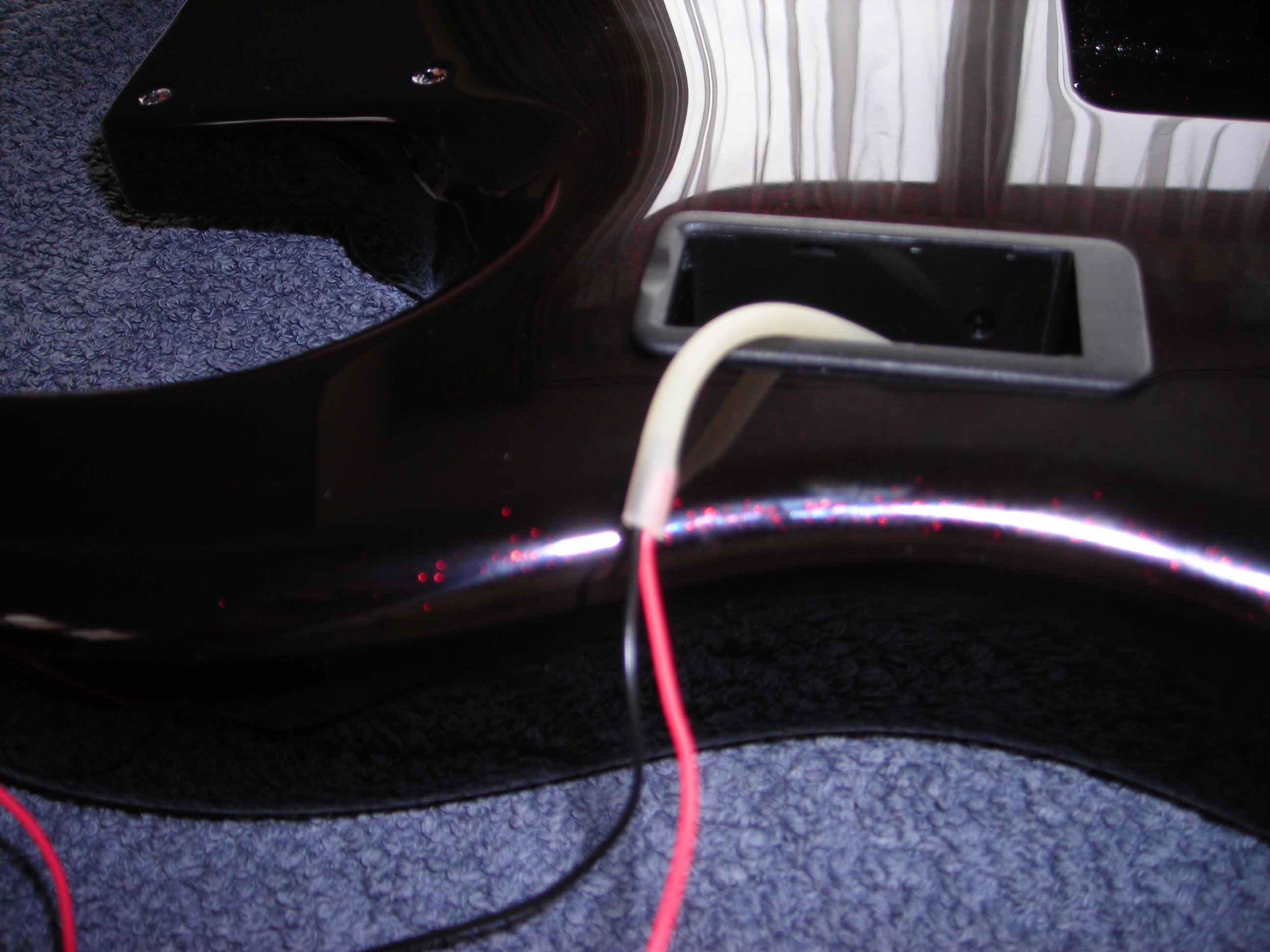

The first step was to get the Non-Fine Tuner Floyd Rose ready. Some updates to do and here are a few photos.

A bunch of parts and some of the tools ready to go.

FloydAssembly1

FloydAssembly1 by

stratamania, on Flickr

We have in addition to the tremolo:

[list type=decimal]

[*]A brass block upgrade

[*]Heavy springs

[*]Some shims for flattening the radius

[*]A Red Bishop tremolo arm

[/list]

Not all are visible in the photo.

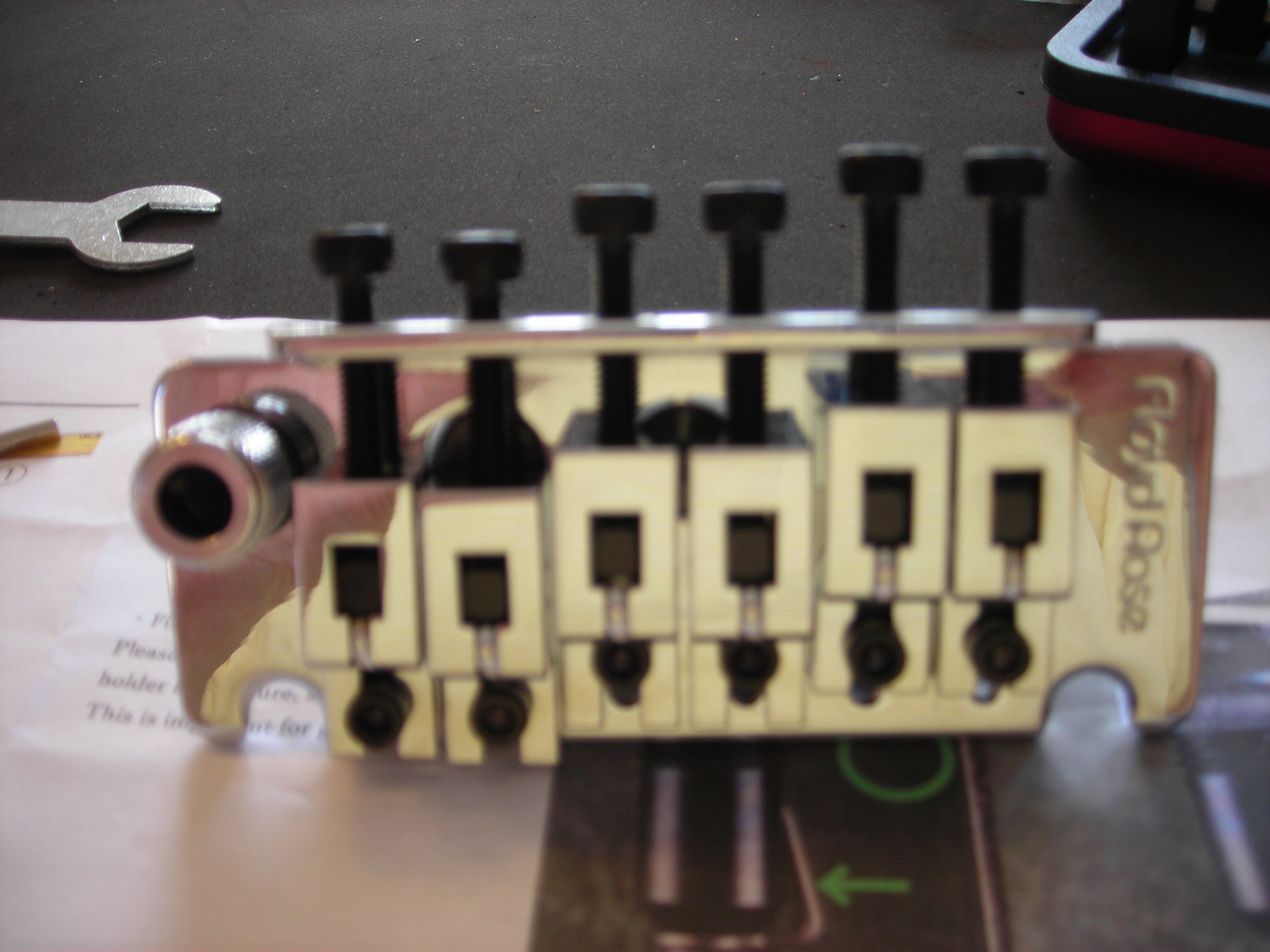

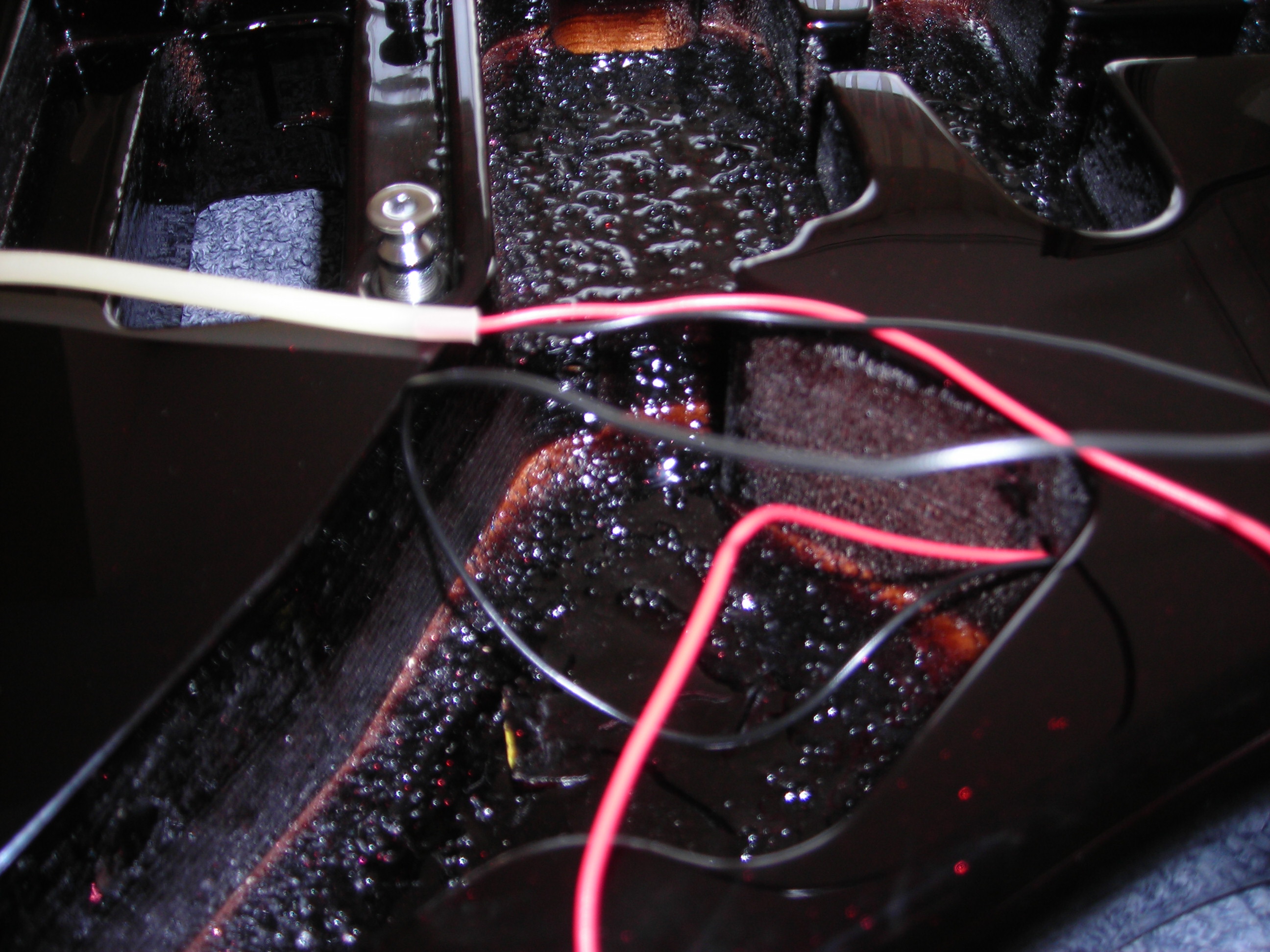

Next getting the saddles off ready to upgrade the block and the arm holder.

FloydAssembly3

FloydAssembly3 by

stratamania, on Flickr

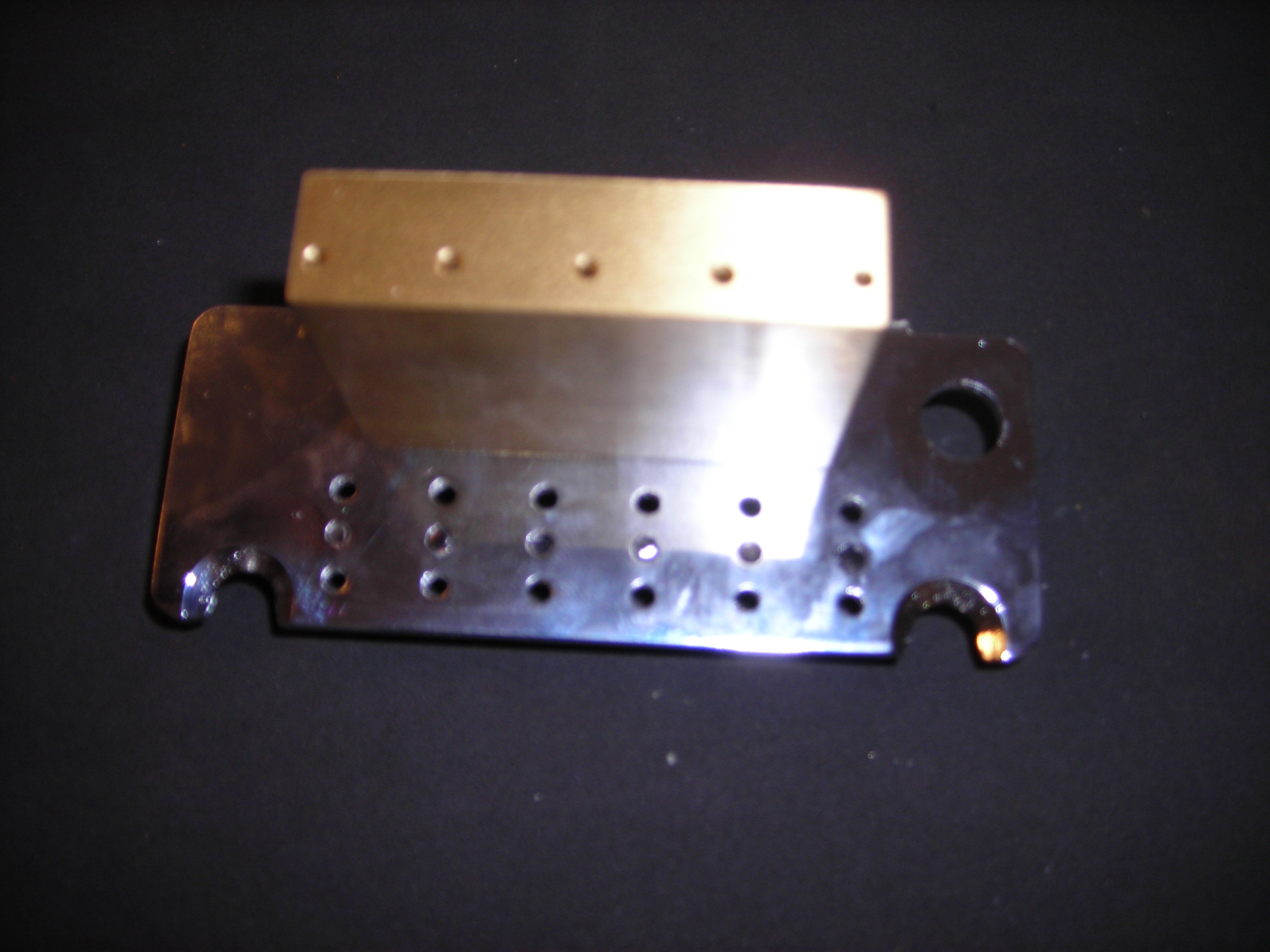

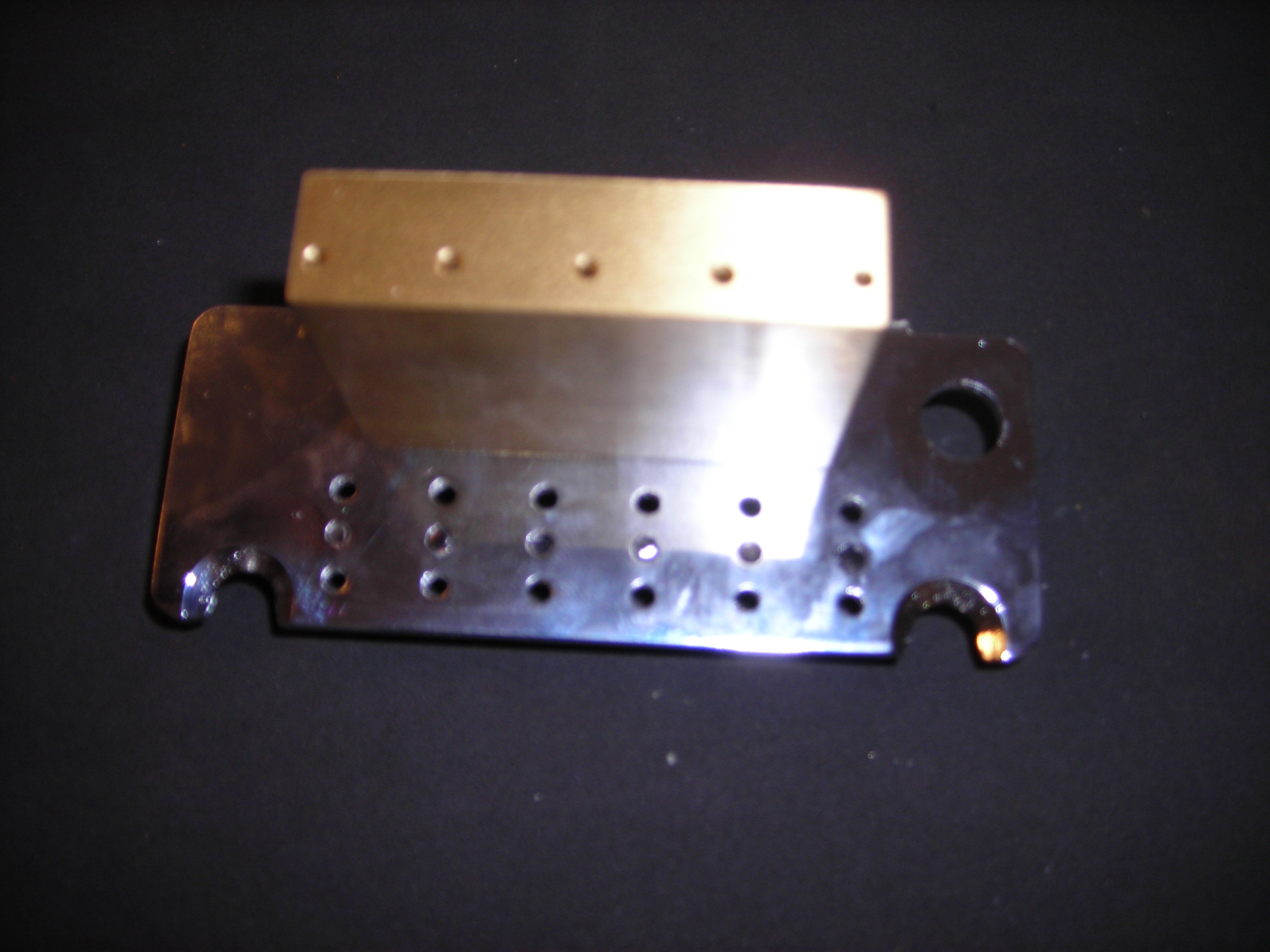

After removing the original block and arm holder here is the new block and arm ready for fitting.

FloydAssembly4

FloydAssembly4 by

stratamania, on Flickr

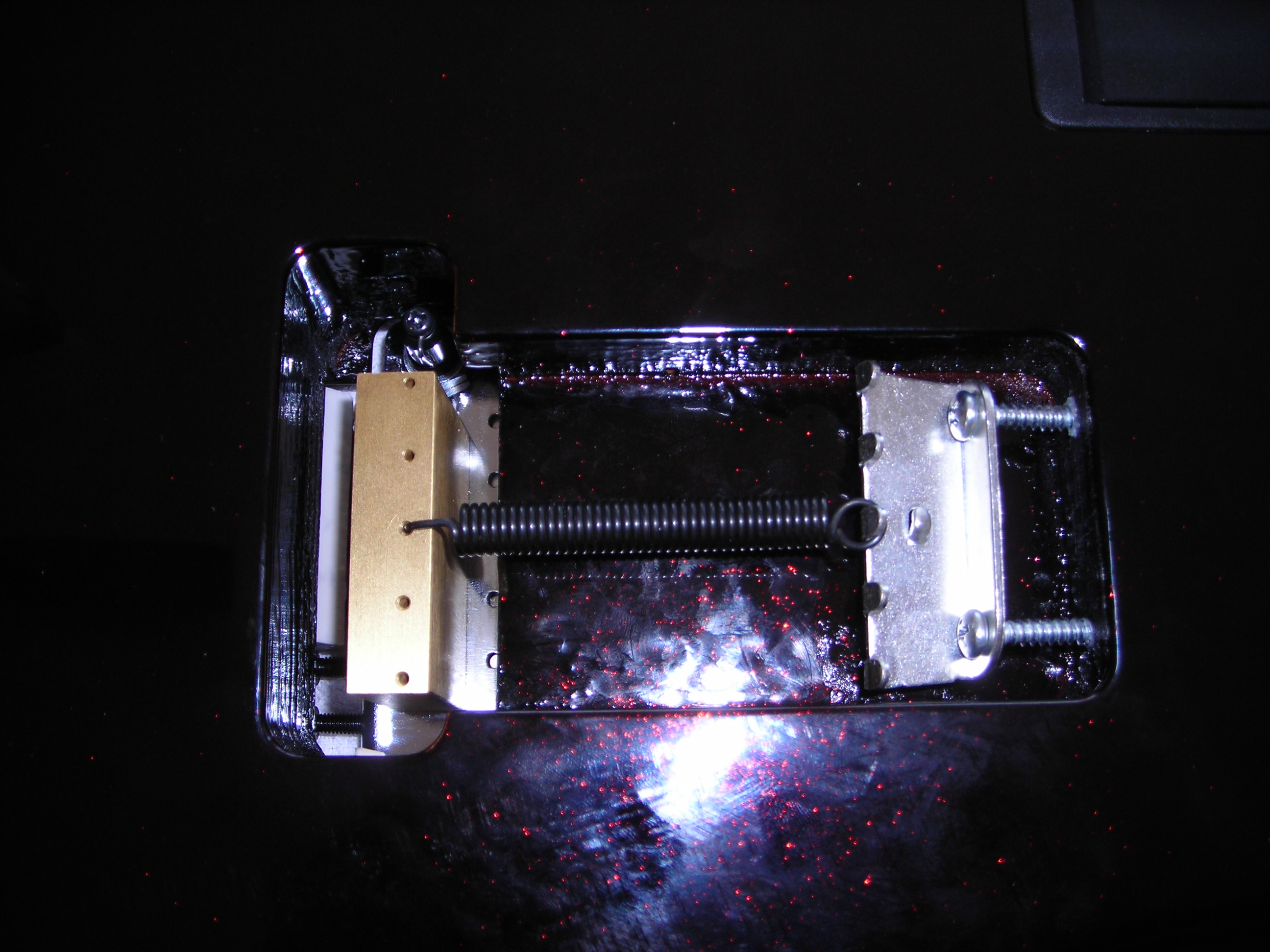

You will notice the brass block is thicker than the original block. Where the Floyd Rose 37mm is marked this fits towards the rear of the bridge similar to the original.

FloydAssembly5

FloydAssembly5 by

stratamania, on Flickr

As described above the last photo this ensures the holes for the springs are towards the front of the bridge where they need to be. The brass block is much thicker than the original so this is important.

FloydAssembly6

FloydAssembly6 by

stratamania, on Flickr

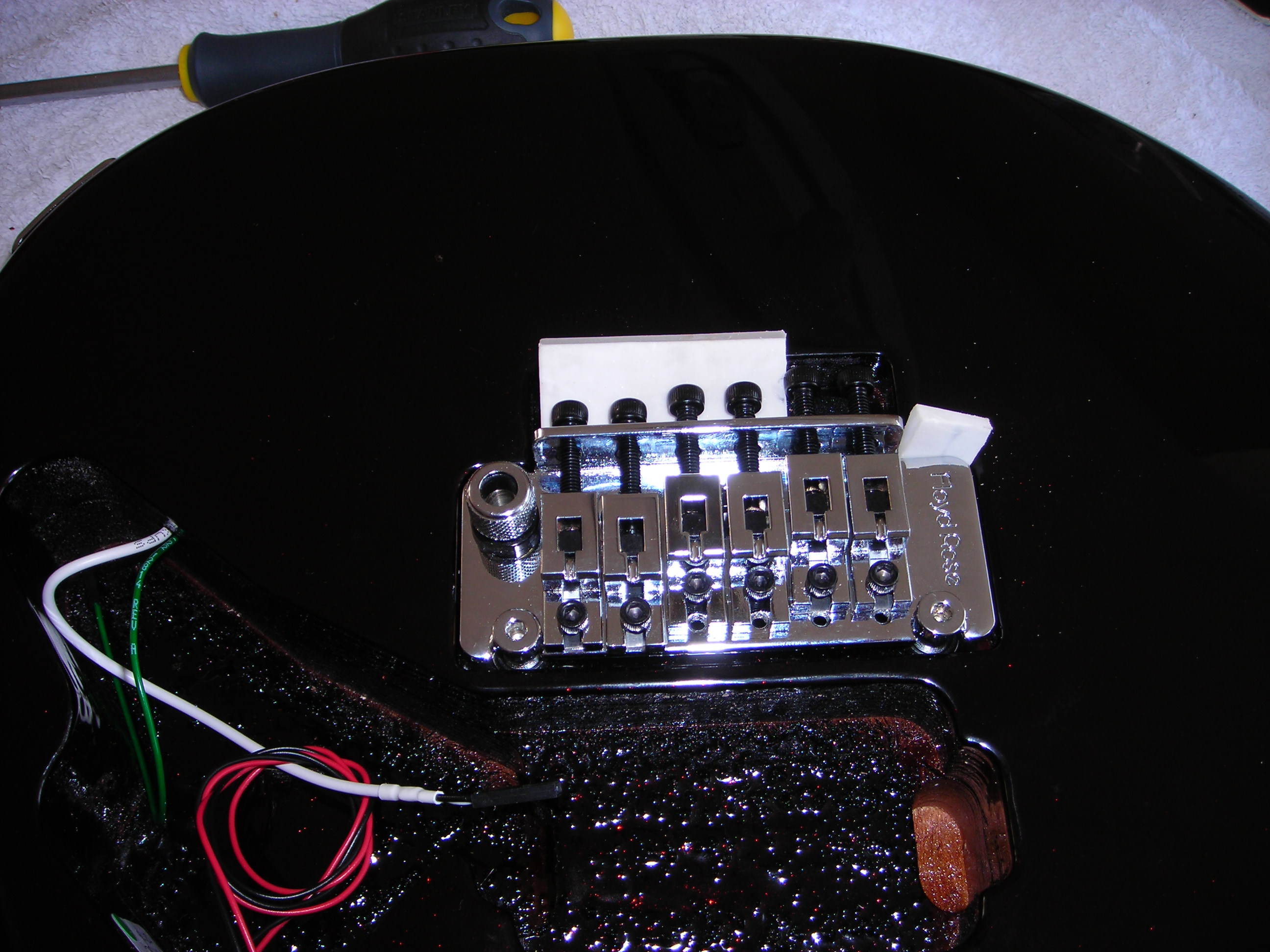

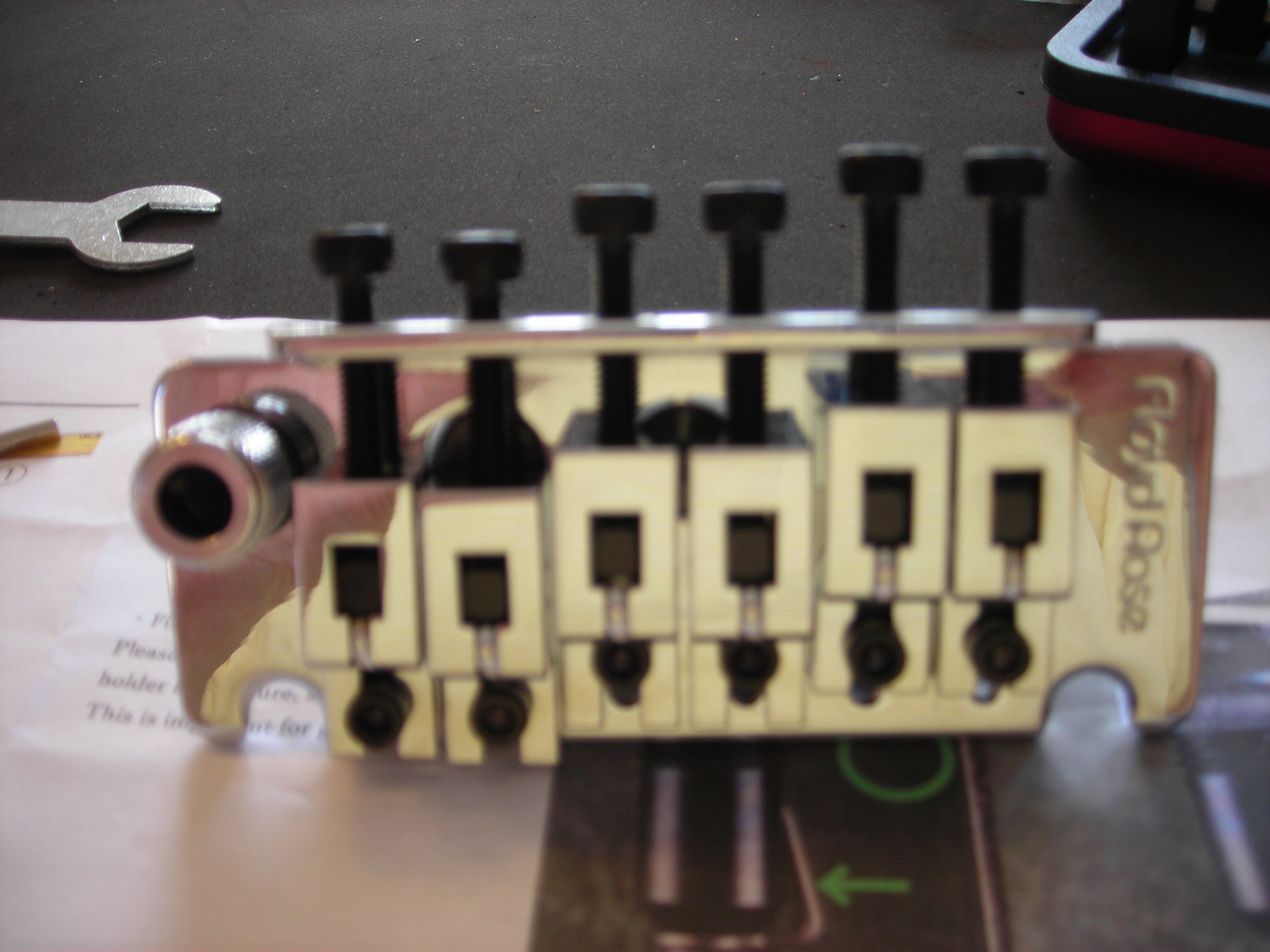

After the block and arm were fitted I positioned some shims to help with flattening the radius ready for the compound radius neck and set up which comes later.

There are two shims below each E string saddle and a single shim below the B and A string saddles. The D and G string saddles have no shims.

FloydAssembly8

FloydAssembly8 by

stratamania, on Flickr

It can also be noticed that I have positioned the B and E saddles machine screws in the forward facing holes and approximated an intonation spread. Of course, it will need to be set up later when the guitar is done. This is just a roughed in and educated guess for now.

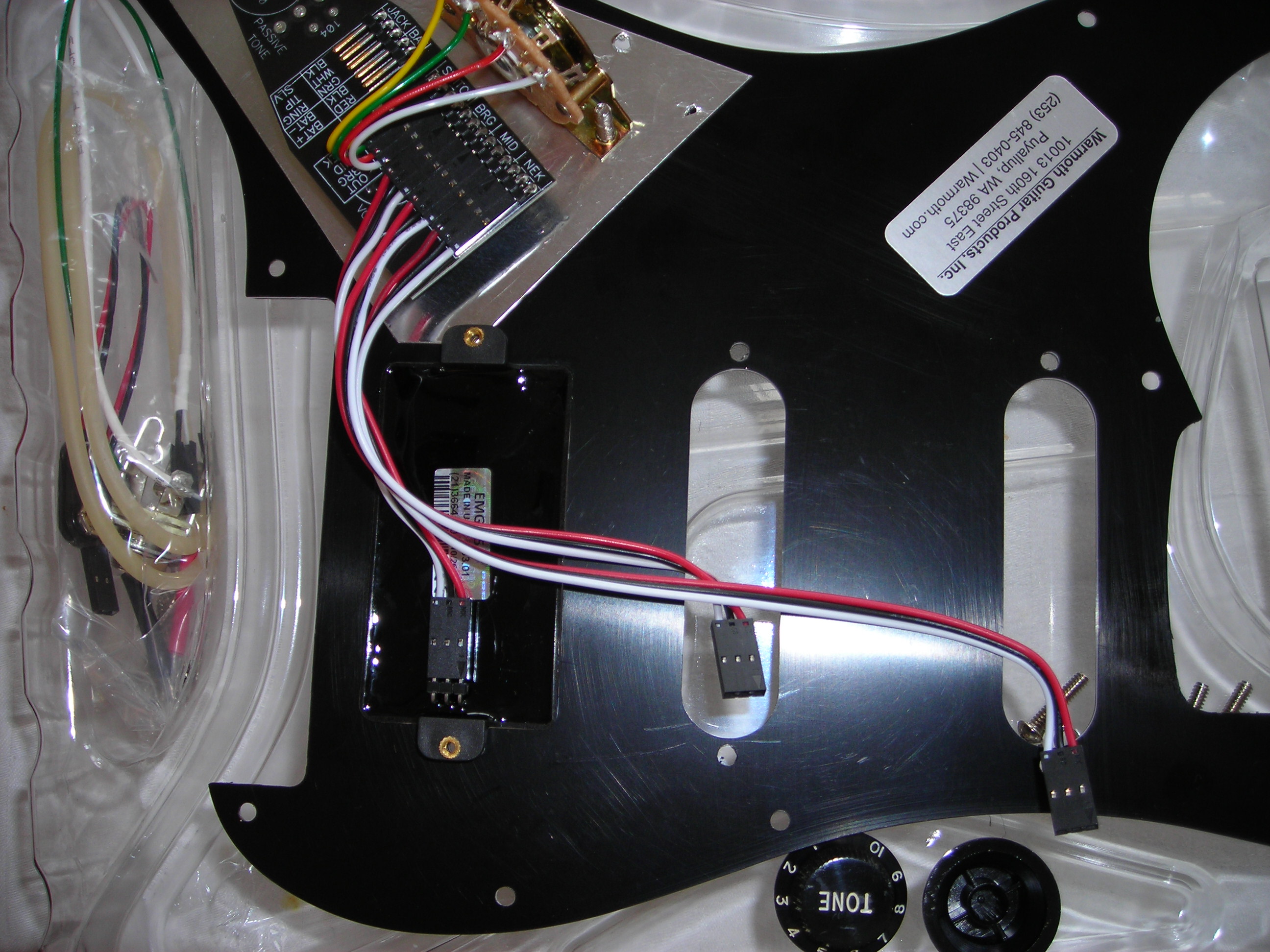

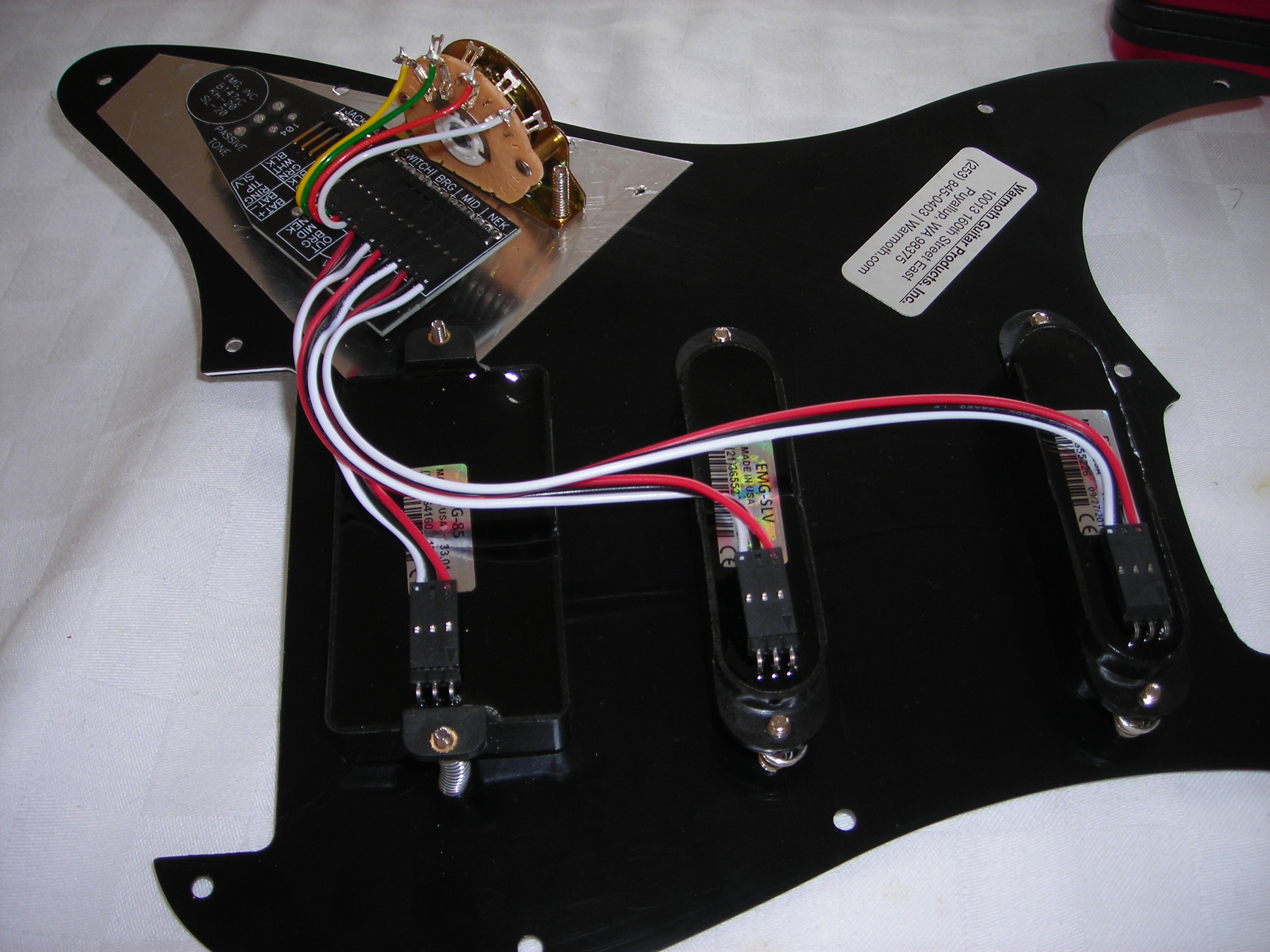

Next up pickguard and pickup preparation.

unofficialwarmoth.com

unofficialwarmoth.com