PhilHill

Hero Member

- Messages

- 1,653

As I am more or less bored presently, I decided to try an experiment with some maple that was lying around unused. Read "experiment" as meaning "just goofing around".

Thought I would see what happens.

.

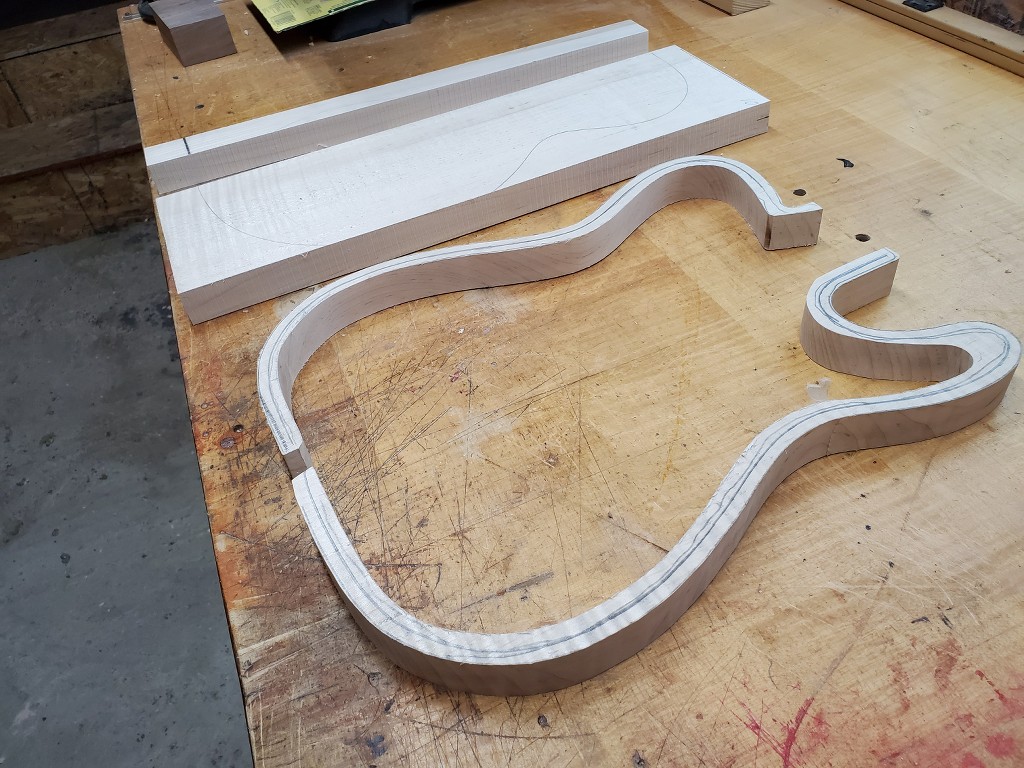

. The large piece on the left is one half of a pair that didn't pass muster for a carve-top, so they had it on clearance for $18.00. Couldn't pass it up. The sides were cut out of one half and I split and book-matched the other half

.

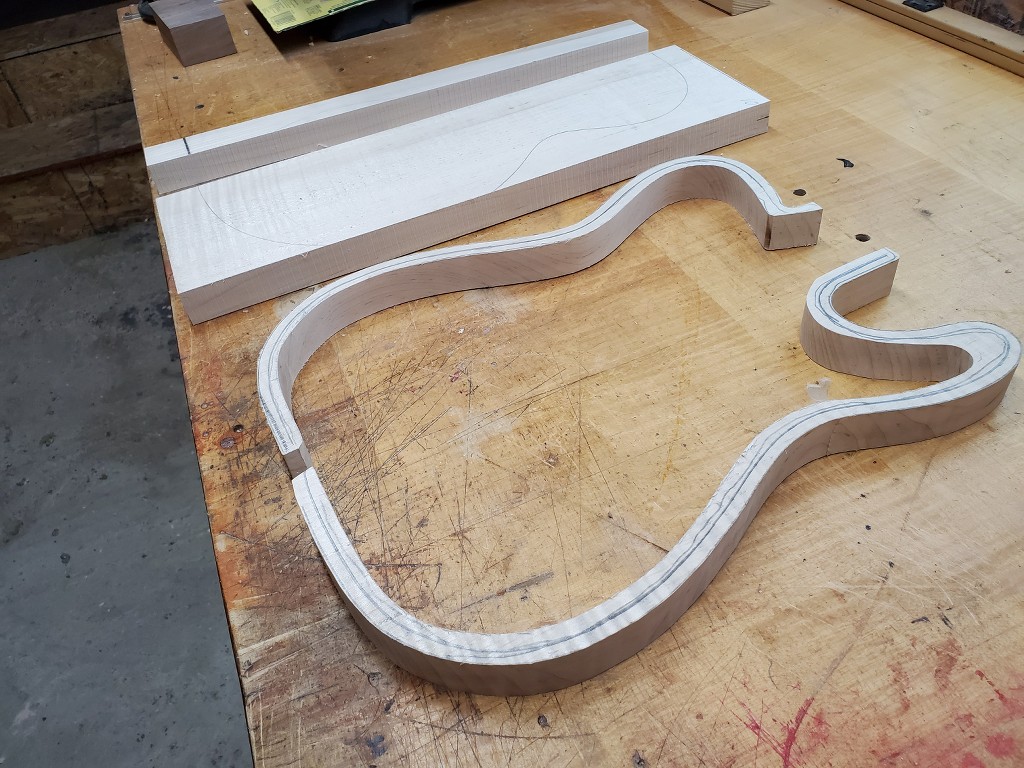

.After that it was a matter of gluing the sides to the top that I had cutout and trimmed, and adding neck and heel blocks.

.

.

.

.

. Had some quarter-sawn walnut that would do for the back, and a smaller piece for a block under the bridge.

.

. The back was only .245 thick so I decided to put some braces to stiffen it up a little.

.

.

.Like I said, we'll see where this goes. So far I've got about $30.00 into it, so I figure even if it doesn't sound good I can always use it for wall art........... :turtle: :turtle:

Thought I would see what happens.

.

. The large piece on the left is one half of a pair that didn't pass muster for a carve-top, so they had it on clearance for $18.00. Couldn't pass it up. The sides were cut out of one half and I split and book-matched the other half

.

.After that it was a matter of gluing the sides to the top that I had cutout and trimmed, and adding neck and heel blocks.

.

.

.

.

. Had some quarter-sawn walnut that would do for the back, and a smaller piece for a block under the bridge.

.

. The back was only .245 thick so I decided to put some braces to stiffen it up a little.

.

.

.Like I said, we'll see where this goes. So far I've got about $30.00 into it, so I figure even if it doesn't sound good I can always use it for wall art........... :turtle: :turtle: