Cagey

Mythical Status

- Messages

- 24,425

If you've ever wondered whether the claim that the Gotoh/Wilkinson vibrato bridges Warmoth sells have the hardened steel base plate they're supposed to have, you may rest assured that they do. Actually, Warmoth doesn't make the claim, Gotoh does.

Why should you care? Three reasons I can think of.

First, being hardened steel, the pivot points for the bridge won't wear unduly fast. This is a Good Thing.

Second, a hardened steel base plate means the string saddles are resting against something that not only isn't going to absorb vibrations, it'll transfer them directly to the "sustain" block and pivot points that are mounted in the body. All that should translate into greater sustain and wider frequency response, so you have a more articulate instrument. Perhaps only a little bit - I don't know how to measure it easily - but it makes sense. In any event, real or imagined, probably a Good Thing

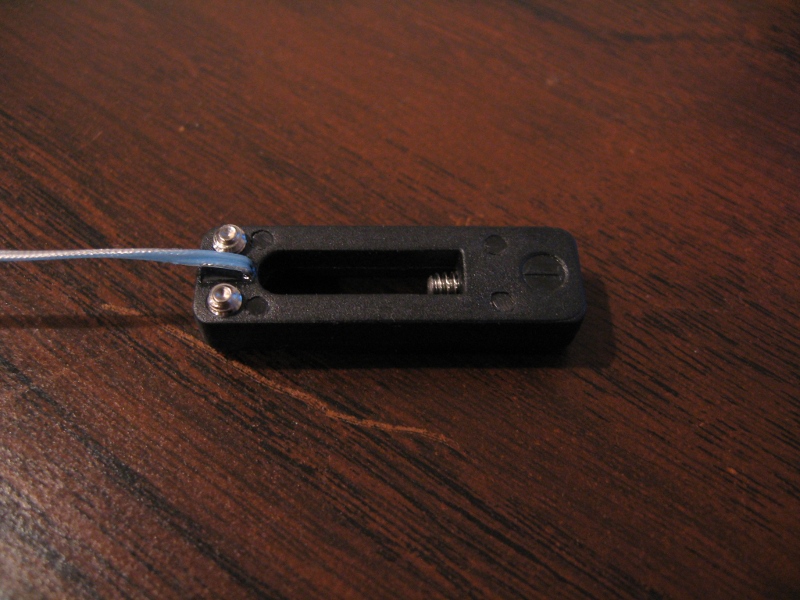

Third, if you get the urge to install Graphtech "Ghost" saddles (Gotoh normally uses stainless saddles) and you want to drill holes in the plate to accommodate the wires so they're not flopping around and looking half-assed. The wire exits the bottom of the saddle...

...so you have to sorta find where on the base it would be not only convenient for the hole, but wouldn't end up creating a wear point on the wire's insulation. Not tough. Install the bridge, string the fiddle up, set the intonation, then mark where the old saddles are. The Graphtech parts are so close dimensionally that you can use the marks.

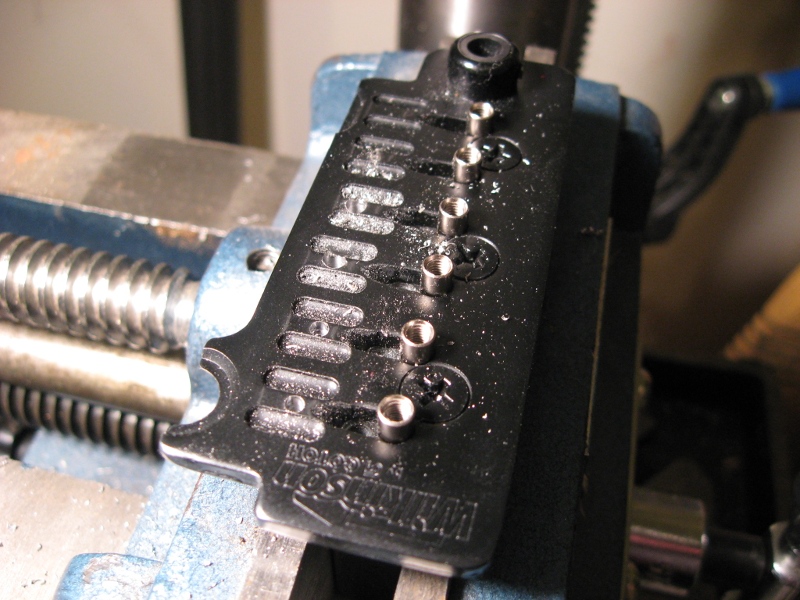

However, drilling hardened steel is no fun at all, which is what prompts this post. I've gone through a goodly number of bits today, some of which are surprisingly expensive, trying to drill clearance holes for the saddle wires on a Ghost retrofit to a Wilkinson bridge. I mean, I could just spit. A HSS bit (waste of time, ruined the bit), then a titanium-coated bit (waste of time, ruined the bit), then a couple cobalt bits (broke 'em), and finally a pure carbide bit (broke it, too). I did manage to get a few pilot holes done in preparation for opening them up a bit more, but the cost has been kinda high (~$20 in bits, and I'm not even half-way there).

As I've come to learn, the harder/sharper the bit, the more brittle it is, so you run into trouble with a regular drill press. I've got a decent Delta unit here, but while they make some good tools, the spindle is still not as strong/true as you have with a milling machine, so the bit wants to bend/flop around under the pressure of an eccentric orbit. PING! There goes the biting end of your bit. Sonofabitch!

So, I ordered some more carbide bits. I'm nothing if not tenacious. The beatings will continue until morale improves! <grin>

Follow-up next week.

Why should you care? Three reasons I can think of.

First, being hardened steel, the pivot points for the bridge won't wear unduly fast. This is a Good Thing.

Second, a hardened steel base plate means the string saddles are resting against something that not only isn't going to absorb vibrations, it'll transfer them directly to the "sustain" block and pivot points that are mounted in the body. All that should translate into greater sustain and wider frequency response, so you have a more articulate instrument. Perhaps only a little bit - I don't know how to measure it easily - but it makes sense. In any event, real or imagined, probably a Good Thing

Third, if you get the urge to install Graphtech "Ghost" saddles (Gotoh normally uses stainless saddles) and you want to drill holes in the plate to accommodate the wires so they're not flopping around and looking half-assed. The wire exits the bottom of the saddle...

...so you have to sorta find where on the base it would be not only convenient for the hole, but wouldn't end up creating a wear point on the wire's insulation. Not tough. Install the bridge, string the fiddle up, set the intonation, then mark where the old saddles are. The Graphtech parts are so close dimensionally that you can use the marks.

However, drilling hardened steel is no fun at all, which is what prompts this post. I've gone through a goodly number of bits today, some of which are surprisingly expensive, trying to drill clearance holes for the saddle wires on a Ghost retrofit to a Wilkinson bridge. I mean, I could just spit. A HSS bit (waste of time, ruined the bit), then a titanium-coated bit (waste of time, ruined the bit), then a couple cobalt bits (broke 'em), and finally a pure carbide bit (broke it, too). I did manage to get a few pilot holes done in preparation for opening them up a bit more, but the cost has been kinda high (~$20 in bits, and I'm not even half-way there).

As I've come to learn, the harder/sharper the bit, the more brittle it is, so you run into trouble with a regular drill press. I've got a decent Delta unit here, but while they make some good tools, the spindle is still not as strong/true as you have with a milling machine, so the bit wants to bend/flop around under the pressure of an eccentric orbit. PING! There goes the biting end of your bit. Sonofabitch!

So, I ordered some more carbide bits. I'm nothing if not tenacious. The beatings will continue until morale improves! <grin>

Follow-up next week.