DangerousR6

Mythical Status

- Messages

- 15,478

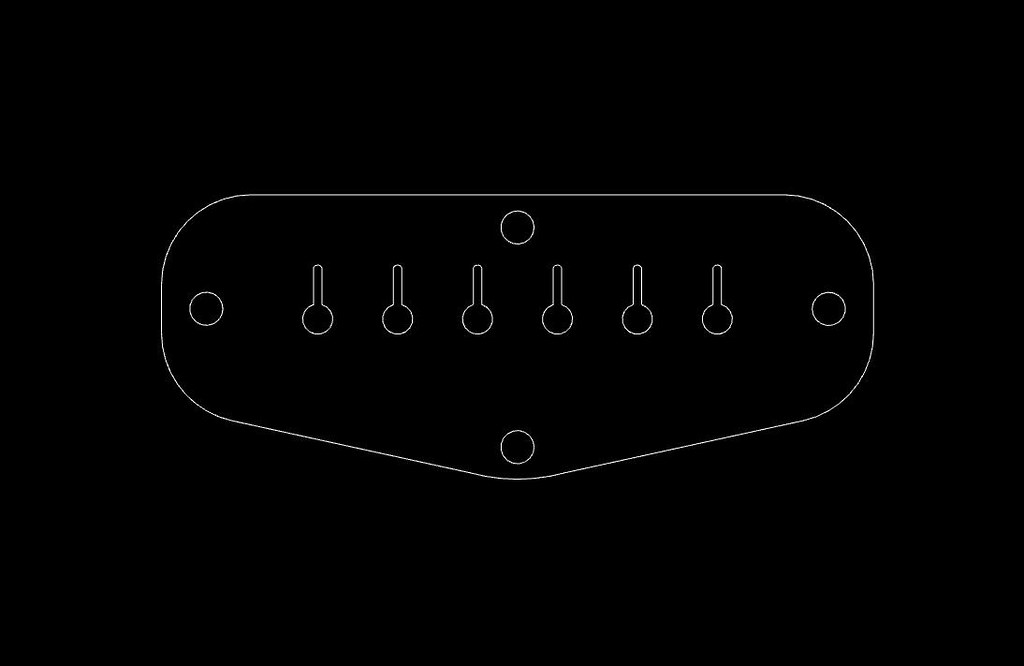

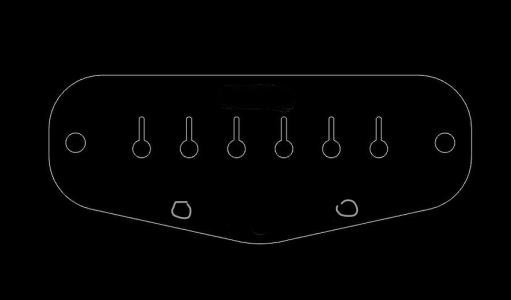

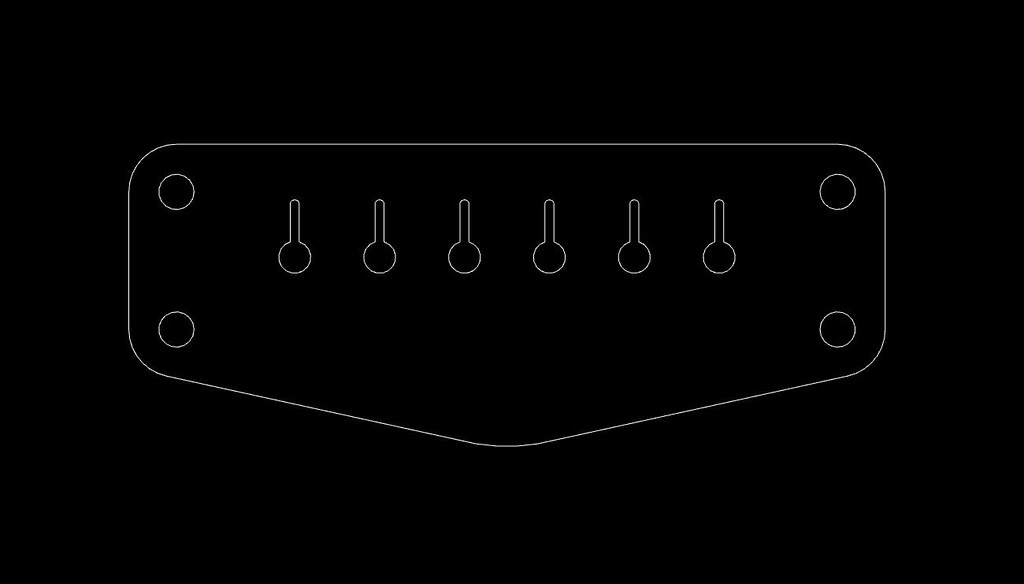

Here's another version slightly fatter on the back end... :dontknow:jay4321 said:Hey so yes that works as is but wouldn’t hate a second version with a little more mass to it, maybe just on the back end

Certainly does the trick though

In other news I’m kind if tired of the string-thru ferrules thing and I have half a dozen guitars with them. My 1st guitar was a POS but the one thing right about it was the little pot metal claw tailpiece. That would be too high (and too ghetto) for the project in mind but the simple hook & go with strings couldn’t be quicker.