ztbishop

Newbie

- Messages

- 3

I tried a Fender pro (full heel thickness with the corner of the heel filed). It doesn't do much at all - still too thick & bulky where the heel pocket starts.

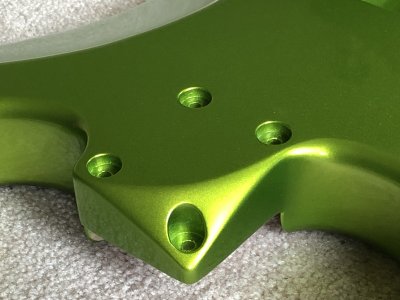

I tried a Fender Strat ULTRA - it felt AMAZING. It both angled the heel thickness similar to Warmoth, and cut the curve out of the heel corner.

I have not had a Warmoth style body (yet).

--So I'm planning a new build and want to order the Contoured strat style body, along with a pre-drilled neck.

Has anyone tried the Warmoth contoured heel and gone the extra step of cutting/filing the corner off (similar to Fender ULTRA) and slapping on the Fender curved heel plate?

Will need to drill a new hole in the body, and then fill and drill a new hole in the neck.

Reason to do this all up-front - I'm going with an unfinished body anyway and can do the carving before painting. Get the best of both designs, similar to the Ultra.

I had a few concerns if the heel pocket would still be strong enough being both thinner and smaller (although Fender does it).

And - if throwing some wood filler in one of the holes of a roasted maple neck (and drilling a new one) would cause any type of issues (weaken the neck, etc).

I tried a Fender Strat ULTRA - it felt AMAZING. It both angled the heel thickness similar to Warmoth, and cut the curve out of the heel corner.

I have not had a Warmoth style body (yet).

--So I'm planning a new build and want to order the Contoured strat style body, along with a pre-drilled neck.

Has anyone tried the Warmoth contoured heel and gone the extra step of cutting/filing the corner off (similar to Fender ULTRA) and slapping on the Fender curved heel plate?

Will need to drill a new hole in the body, and then fill and drill a new hole in the neck.

Reason to do this all up-front - I'm going with an unfinished body anyway and can do the carving before painting. Get the best of both designs, similar to the Ultra.

I had a few concerns if the heel pocket would still be strong enough being both thinner and smaller (although Fender does it).

And - if throwing some wood filler in one of the holes of a roasted maple neck (and drilling a new one) would cause any type of issues (weaken the neck, etc).