reluctant-builder

Hero Member

- Messages

- 816

I hate soldering to the backs of pots. All of my guitars have come this way from the factory, and so if I even want to undo it, I've got to apply some head to the pot housing. The solder in my Swede must be from Hell; it doesn't melt. It's not my iron; it works fine in every other application and my tech, who uses a more powerful iron than my 40W, also had trouble getting the factory solder to melt. The pots sure get hot, though. Oh, joy.

Cagey is big proponent of Solder Lugs. I don't blame him; they seem like a great idea. I've got four that he sent me, lying in wait to use on my Jazzmaster build. But I don't want to buy more of them unless I've got things enough to order that would justify the shipping cost ... so I'm looking for an alternative grounding method to Cagey's alternative grounding method.

No backs of pots. No solder lugs.

So, what, then?

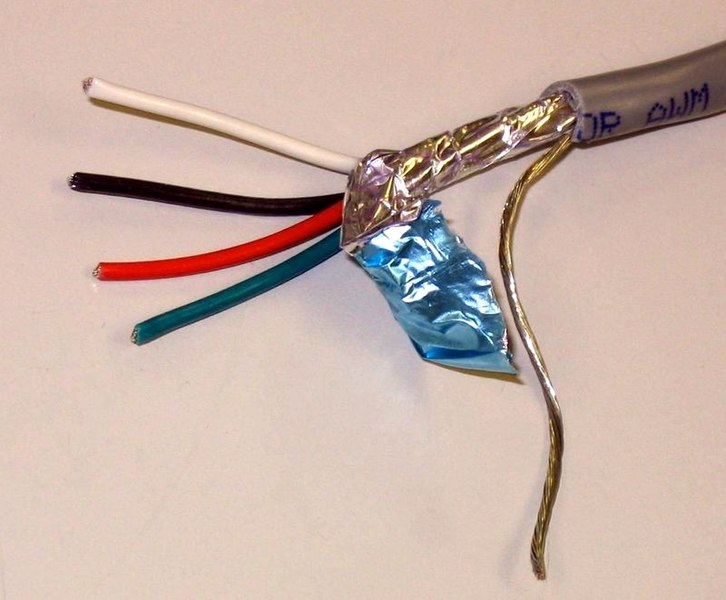

tfarny mentioned "Star Grounding" and the concept sounds interesting. I'd be all set to do it, but I'm kept at bay by that every wire in my Swede seems to have a hot portion and a bare, ground portion. The wires are, in fact, two wires, one with white insulation, one with no insulation, both wrapped in a gray outer layer.

This means that every connection in my guitar has a hot and a ground.

If were to remove all the wire and try to run new 24 AWG wire in its stead, which is just one spool of copper wire with plastic insulation -- no bare wire companion -- how would I effectively ground the guitar, with the absence of these bare wires?

I've attached what is probably absolute nonsense, but I am trying to illustrated how I'd want to join all things that would normally ground to the back of pots and have them run to the pup toggle, the tone filter toggle and to the jack sleeve.

Edit: I modified the diagram again because, after disassembling the wiring, I could take out the tone filter switch and see now that there is a jumper wire between the two hot outer terminals.

Cagey is big proponent of Solder Lugs. I don't blame him; they seem like a great idea. I've got four that he sent me, lying in wait to use on my Jazzmaster build. But I don't want to buy more of them unless I've got things enough to order that would justify the shipping cost ... so I'm looking for an alternative grounding method to Cagey's alternative grounding method.

No backs of pots. No solder lugs.

So, what, then?

tfarny mentioned "Star Grounding" and the concept sounds interesting. I'd be all set to do it, but I'm kept at bay by that every wire in my Swede seems to have a hot portion and a bare, ground portion. The wires are, in fact, two wires, one with white insulation, one with no insulation, both wrapped in a gray outer layer.

This means that every connection in my guitar has a hot and a ground.

If were to remove all the wire and try to run new 24 AWG wire in its stead, which is just one spool of copper wire with plastic insulation -- no bare wire companion -- how would I effectively ground the guitar, with the absence of these bare wires?

I've attached what is probably absolute nonsense, but I am trying to illustrated how I'd want to join all things that would normally ground to the back of pots and have them run to the pup toggle, the tone filter toggle and to the jack sleeve.

Edit: I modified the diagram again because, after disassembling the wiring, I could take out the tone filter switch and see now that there is a jumper wire between the two hot outer terminals.