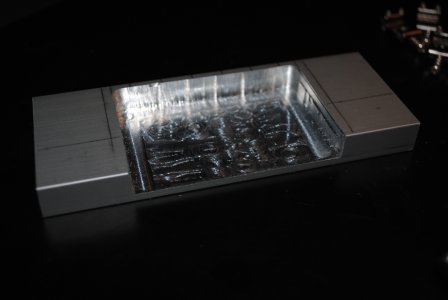

Well there is A LOT of work yet to do....drill holes, cut overall depth to size (only had 2" material at work), shape/file the curves and when all that is done....satin black annodizing. Our copy router at work did an ok job, more clean up than I would like but....whagonnado.

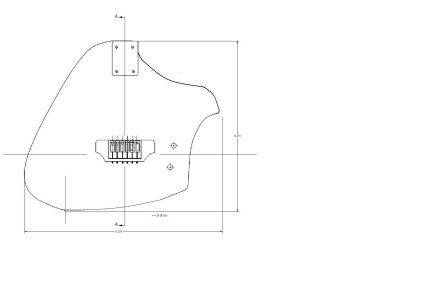

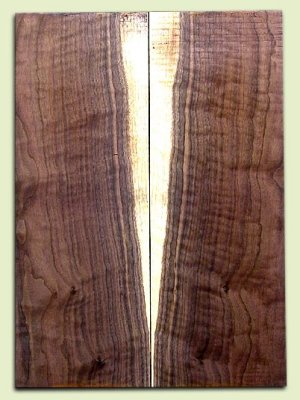

This is going on my next build and will be a piezo pickup only guitar. Since I'm doing an ergo guitar a standard strat bridge would look a little small in comparison to the body, plus this bridge should resonate quite nicely.

Here are a couple pics....haven't got started yet so its a little rough.

This is going on my next build and will be a piezo pickup only guitar. Since I'm doing an ergo guitar a standard strat bridge would look a little small in comparison to the body, plus this bridge should resonate quite nicely.

Here are a couple pics....haven't got started yet so its a little rough.