After some delay (I just

had to buy a few new pedals, some pickups, an amp, a new speaker cab, a new talkbox... I

had to, I swear), finally got the neck order in and it turned up this morning.

Not got any full pictures because I've already started drilling bits and pieces and such, though I did take thirty seconds to take two quick snaps of things I think need to be mentioned ASAP.

The first is that rather than ship in the usual Warmoth box, this neck came in a triangular box with next to no support. A single sheet of bubblewrap is all that protected it during its overseas journey. That's a little annoying, though thankfully everything seems to be perfectly in order.

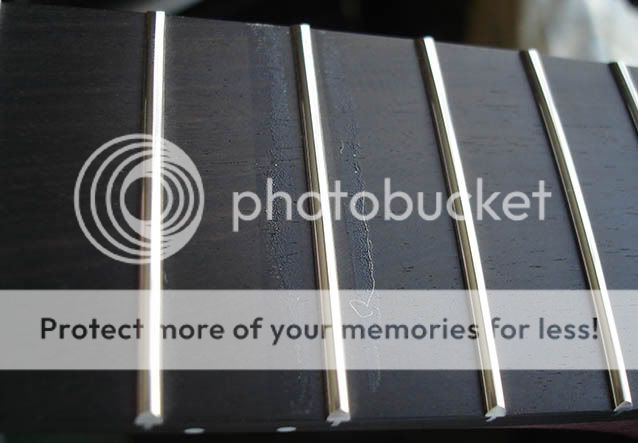

What was really annoying was that Warmoth stuck some label on at the 12th fret and a layer of hardened glue is well and truly stuck to the fretboard:

I dunno what I can use that will strip set glue off without murdering the ebony. I've tried the usual fretboard cleaners, prep and conditioner and it's not shifted it. Considering how many type sof wood conditioners I have I think I might try just taking the ol' acetone to it, should clear the glue and whatever damage it does do I should be able to remedy. Still, I'd like to see if anyone has any other suggestions first. Don't really fancy the idea of sending it back as damaged when it's taken so long to get here and when the neck stock is so special. Speaking of, interesting picture #2...

I know it's not exactly AAAAA-grade, but has anyone heard of flame purpleheart before? Phone camera shot at the window doesn't show it off amazingly, it's a little more defined in person, but anyhoo. I thought it was a more uniform colour, but there's definitely some light flame figuring there, especially when you catch it at just the right angle. It's quite charming, my first Warmoth neck (maple) had the same hint-of-flame thing going on and I love that (odd since I'm typically against heavily figured woods, more of a plain top man myself). Does make me wonder if a full, high-grade flame purpleheart or bloodwood neck would ever be possible.

Obviously I've not got it strung up and playing just yet, but I've got to say this is already the nicest feeling neck I've ever played. I doubt I'll ever be able to use a finished neck again after this.

Should have it all bolted together, wire and strung up within the next couple of days. I'm just waiting on some pickups now. While I've been waiting for the neck I gave the Bare Knuckles a go on one of my other Teles which has very similar specs (it being the usual flattop and having a maple neck stock vs purpleheart being the only noticable differences) and the tone was so, so far away from what I want with this guitar that I doubt the small difference between the two will make up for 'em. Had a good classic rock tone but didn't really sound good enough at the two extremes for my taste. So they're in the parts drawer, probably going to do a magnet swap on 'em, put some covers on and stick those into one of my many Les Pauls. Not bad pickups, but just not what I was expecting nor anywhere even remotely close to what I was after for this.

Instead, I'm taking a gamble on some DiMarzios. I've never liked DiMarzio pickups before but everyone and their mother has been telling me that a PAF Pro in the neck and an Evo 2 in the bridge is exactly what I want and it can't hurt to try. Considering the Evo 2 is very close to the Evo 7 and I use the Evo 7 in one of my 7-strings, I at leats feel fairly confident there, if not so much the neck PAF Pro. Worst comes ot the worst I can do some interesting coil mixing and magnet swapping with the Bare Knuckles.

I think I perhaps need to start learning some Poison or Twisted Sister songs to christen this guitar with...