elstoof

Junior Member

- Messages

- 85

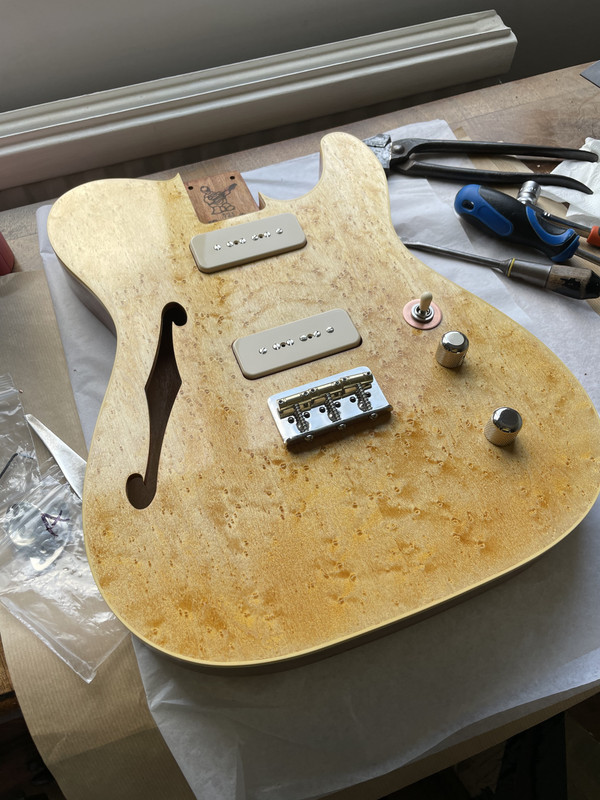

Thought I'd start a little progress thing for this ode to Birdseye, it's my first time assembling a guitar, first time with working with Warmoth parts, and it's been very enjoyable so far. I ordered the body first but my adventures with wood dyes changed my plans and decided to alter the core wood to mahogany, so the neck arrived first. It's Birdseye maple with a unique choice Birdseye fretboard, unfinished.

The wood looked fantastic straight out of the box, so good I ended up ordering some more stuff. Anyway I thought I'd have a go levelling the frets, never done it before and probably could have gotten away without it but I bought the tools so better use them. There were 2 that were slightly low, anyway, now they're not. Next up was tung oil, pure stuff not the finish. It's easy enough to work with, wipe it on, wipe off the excess, leave it, sand occasionally, if you still have a count of how many coats you've done it's not enough. When it's "done" i gave it a light rub with some 2500 abrasive and it's like buttah.

Edited to add how it is now

The wood looked fantastic straight out of the box, so good I ended up ordering some more stuff. Anyway I thought I'd have a go levelling the frets, never done it before and probably could have gotten away without it but I bought the tools so better use them. There were 2 that were slightly low, anyway, now they're not. Next up was tung oil, pure stuff not the finish. It's easy enough to work with, wipe it on, wipe off the excess, leave it, sand occasionally, if you still have a count of how many coats you've done it's not enough. When it's "done" i gave it a light rub with some 2500 abrasive and it's like buttah.

Edited to add how it is now