Tonar8353 said:

Im curious if using a sealer like bullseye before gainfilling mahagany is going to make it less likely to sand out of the pours??

With traditional fillers the advantage of sealing prior to grain filling it twofold, many grain fillers tend to color the wood to some extent so if the surface is sealed then the natural color of the wood changes less. This is really important when using dark grain filler where one only wants the dark color in the deep grain of the wood. The second advantage is it helps but does not eliminate the filler from shrinking in as bad as it does on unsealed wood. Unsealed wood draws moister out of fillers so the materials tend to shrink more dramatically than when it is setting on a seal surface.

The best way to seal wood prior to filling is with wash coats meaning heavily thinned. A wash coat tends to flow down into the pours better and soak into the wood more deeply so that it has a more effective sealing action.

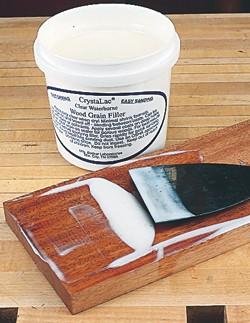

I have a related question to this, but just on a different wood type. I have Timbermate grain filler and I was testing it on a small piece of wood, but I didn't like how much it tinted the wood and also tinted darker in some spots. It filled the grain just fine, but I was wondering for a Goncallo headstock could someone get away with just using Zinsser's sanding sealer. The chunk of wood isn't the same tint or pore quality of Goncallo, but using a small chunk of cotton fabric around a few cotton balls I was able to apply several thin layers which made the shallow grain dissapear alltogether. To test this I applied grain filler on half and nothing on the other half. It wouldn't work on most woods, but it seems like you can apply a few thin bonding layers and sand down, then build up more layers without a grain filler. If this method is bogus, I could very well apply the method that you just said Tonar. I also would like to add that the Timbermate has a smell that is closely related to dookie. :laughing7: