ragamuffin

Hero Member

- Messages

- 1,702

A continuation of the Dreaming up a Mango Tango thread. I said it was just a dream but it quickly started to become a reality! (or at least a fever dream)

I've been sick in bed for like five days, and that does things to a man's resolve. First you start browsing the internet, then you find some sick dealz, and you resist for a few days but eventually you cave to your desires.

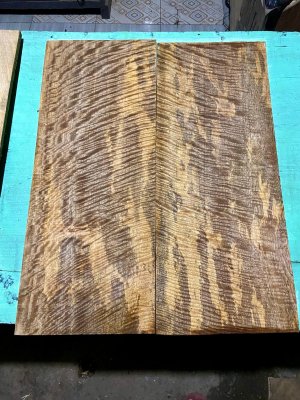

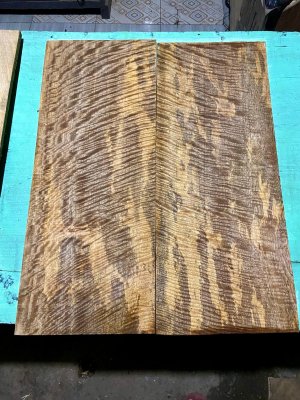

Today I was a bad boy and made my first two purchases towards the build: a lovely figured mango drop top and a minty secondhand Van Dyke Harms telecaster half bridge!

This is the top that I settled on and an updated mockup of what the build might look like:

The "building" part of this build won't be starting until this Fall at the earliest, but this thread will be my spot for updates and acquisitions.

Anybody have suggestions for body wood or neck meat? As of now the plan is a mahogany or korina core and a dark fretboard wood.

I've been sick in bed for like five days, and that does things to a man's resolve. First you start browsing the internet, then you find some sick dealz, and you resist for a few days but eventually you cave to your desires.

Today I was a bad boy and made my first two purchases towards the build: a lovely figured mango drop top and a minty secondhand Van Dyke Harms telecaster half bridge!

This is the top that I settled on and an updated mockup of what the build might look like:

The "building" part of this build won't be starting until this Fall at the earliest, but this thread will be my spot for updates and acquisitions.

Anybody have suggestions for body wood or neck meat? As of now the plan is a mahogany or korina core and a dark fretboard wood.