alexreinhold

Senior Member

- Messages

- 739

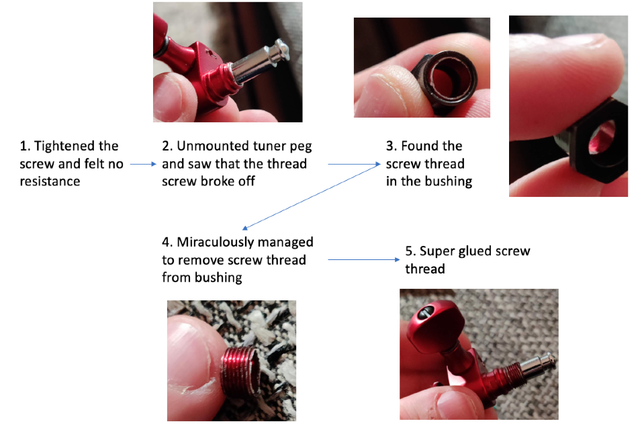

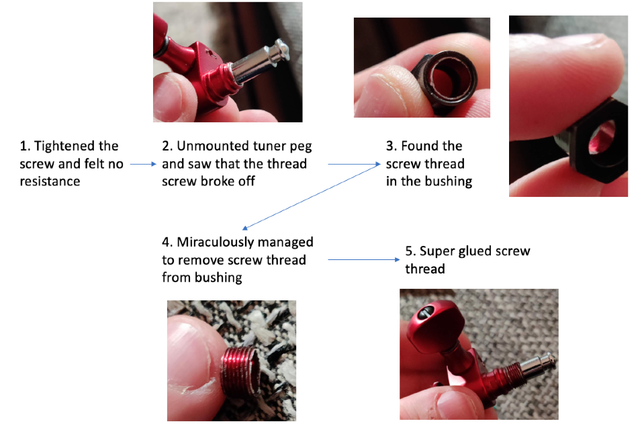

First time using Sperzel tuners and I ran into a very frustrating problem. I installed them exactly as per how they are supposed be installed.

Now here's the important part - BEFORE I tightened the nut of the E-string tuner, the screw thread of the nut had already given up and dissolved itself from the tuner. There was no force applied whatsoever. I noticed the moment I tried (!) to tighten the nut - again, not after I tightened. When I took out the nut, I couldn't believe my eyes. So with a lot of work (and a screw that was just the right size) I managed to pull out the ripped off screw thread from the nut. The only option I saw was to super-glue it back to the tuner. It actually works but when I tune, the nut also moves slightly - so it's an intermediate solution at best.

The frustrating part about this is that I live in Europe and got them custom made from the US - so replacing them will be costly and time consuming. Also, the fact that these are EZ Mount makes things worse because I can't screw them into the headstock. Has anyone of you had similar experiences with Sperzel? My other guitars have locking tuners from Fender, Kluson, Planet Waves and Schaller and I NEVER had any problems with those. Below is a picture of what happened:

Now here's the important part - BEFORE I tightened the nut of the E-string tuner, the screw thread of the nut had already given up and dissolved itself from the tuner. There was no force applied whatsoever. I noticed the moment I tried (!) to tighten the nut - again, not after I tightened. When I took out the nut, I couldn't believe my eyes. So with a lot of work (and a screw that was just the right size) I managed to pull out the ripped off screw thread from the nut. The only option I saw was to super-glue it back to the tuner. It actually works but when I tune, the nut also moves slightly - so it's an intermediate solution at best.

The frustrating part about this is that I live in Europe and got them custom made from the US - so replacing them will be costly and time consuming. Also, the fact that these are EZ Mount makes things worse because I can't screw them into the headstock. Has anyone of you had similar experiences with Sperzel? My other guitars have locking tuners from Fender, Kluson, Planet Waves and Schaller and I NEVER had any problems with those. Below is a picture of what happened: