Prometheus

Junior Member

- Messages

- 135

Okay here goes with another chapter. Nobody complained about the excessive detail last time, so here’s more.

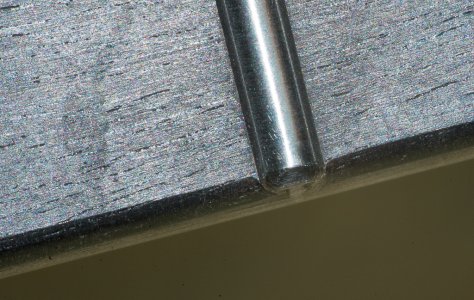

It was time to deal with fine-tuning the neck. First up, those sharp frets, and sharp fingerboard edge. Warmoth leaves the fingerboard edge at a very sharp 90-degrees, and the frets filed to about 35 degrees, and those suckers are sharp. Besides, it’s really dry here, and the neck had already shrunk a bit, leaving the fret tines exposed. Sort of like a barbed-wire fence.

So I made myself a bevelling tool, like the Stew-Mac acrylic one, from a block of maple and a single-cut bastard file. I just cut a slot in the maple to fit the file, and a couple of screws across the cut held the file in place. I cut it a tad shy of 35 degrees. I also rounded out the working surface of the block a bit, the better to fit the radius of the fingerboard.

Running this down the neck makes a terrible screeching sound. Not loud, but unnerving. I fiddled with the angle a bit, by eye, to round out the fingerboard angle, and plane down the exposed tines. A few very light gentle swipes on either side yielded a nicer gentler curve-to-flat intersection, no exposed fret ends, and the fret ends at 35 degrees.

It was time to deal with fine-tuning the neck. First up, those sharp frets, and sharp fingerboard edge. Warmoth leaves the fingerboard edge at a very sharp 90-degrees, and the frets filed to about 35 degrees, and those suckers are sharp. Besides, it’s really dry here, and the neck had already shrunk a bit, leaving the fret tines exposed. Sort of like a barbed-wire fence.

So I made myself a bevelling tool, like the Stew-Mac acrylic one, from a block of maple and a single-cut bastard file. I just cut a slot in the maple to fit the file, and a couple of screws across the cut held the file in place. I cut it a tad shy of 35 degrees. I also rounded out the working surface of the block a bit, the better to fit the radius of the fingerboard.

Running this down the neck makes a terrible screeching sound. Not loud, but unnerving. I fiddled with the angle a bit, by eye, to round out the fingerboard angle, and plane down the exposed tines. A few very light gentle swipes on either side yielded a nicer gentler curve-to-flat intersection, no exposed fret ends, and the fret ends at 35 degrees.