War_in_D

Senior Member

- Messages

- 239

Fat Pete, THANK YOU!

Thank you for ALL of that info, but I found this part especially helpful. My bit is also ~2" and has bearings on both the top/bottom. It never occured to me to flip the body over, allowing for ALL the cuts to move from right to left (and avoiding trying to climb cut on a router table)! I can see now why the top horn did what it did.... twice.. LOL The bit was basically acting like a gouge. I just got lucky on that walnut body, I guess.

Thanks to PhilHill for the original pattern, and thanks again Fat Pete for that additional info. Much appreciated!

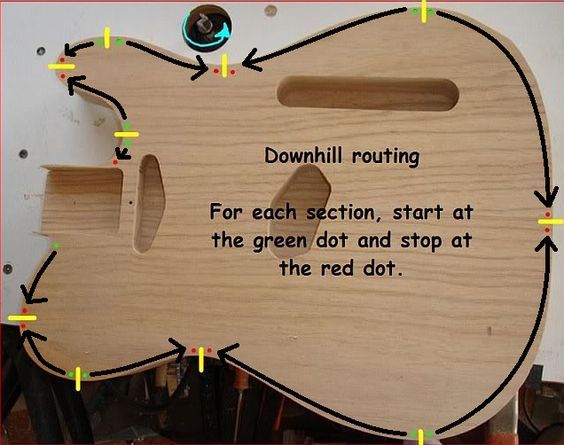

Fat Pete said:Regarding the uphill/downhill thing, here's another pic:

I always try to stick to this, but never route the 'wrong way', always moving the workpiece from right to left - I cut the full thickness of the body using a 50mm ~ 2" cutter with shank and end bearings which allows me to do the cuts shown as clockwise on the above pic with the template on top, then flip the body over to do the rest.

Thank you for ALL of that info, but I found this part especially helpful. My bit is also ~2" and has bearings on both the top/bottom. It never occured to me to flip the body over, allowing for ALL the cuts to move from right to left (and avoiding trying to climb cut on a router table)! I can see now why the top horn did what it did.... twice.. LOL The bit was basically acting like a gouge. I just got lucky on that walnut body, I guess.

Thanks to PhilHill for the original pattern, and thanks again Fat Pete for that additional info. Much appreciated!