Prometheus

Junior Member

- Messages

- 135

Hi all. Well, here I am again, asking for help. I'm posting this in "Tips and Tricks", and while I'm just asking questions, I'm hoping others' answers will fit the bill for "tips".

It looks as though my body and neck will ship in the foreseeable future, and I'd like to get myself straightened out for the process of mounting the neck. I plan to use threaded inserts. Yes, I've read the relevant threads here, and they've been a big help. (special thanks to Cagey for all his pointers, esp. http://unofficialwarmoth.com/index.php?topic=22486.msg333429#msg333429).

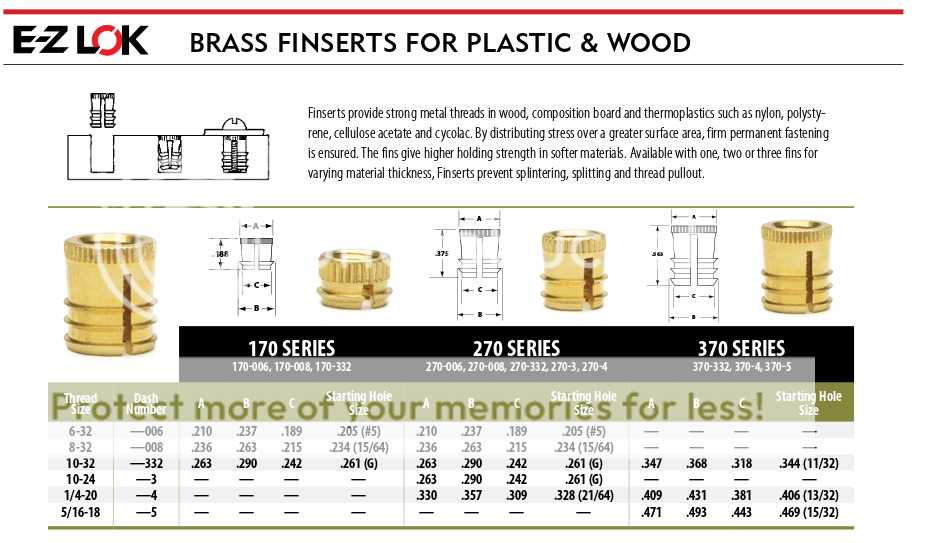

I have a full-sized drill press, and know how to use it. And various doo-dads for positioning and fixing, including an XY vise. And I have the threaded inserts on hand - both the EZlok ones as well as the larger-threaded sharp ones. And I have the ferrules and machine screws, drill bits (regular, brad point, and forstner), and taps for the EZloks. And soap and wax. And some hard maple stock to practice on. I might be shy on the courage though - but hey, one of our family mottos is "God hates a coward", so I'll be heading in.

So what's my question? Well, I want confirmation and advice on the order of business. Neither the neck nor body will have any holes in them. My biggest concern is getting everything where it should be. So here's my current plan:

1) Pray.

2) Measure, measure, measure, and find the right position for the mounting holes. Narrow enough so that the inserts will have enough clearance from the edge of the neck, and wide enough so that I maximize the strength and stability of the join, without the furrules. Mark locations on body.

3) Dry fit the neck and find some way to keep it there. Creative and careful application of clamps is in order. Neck fit must be 100% correct, and must not move a whisker during the drilling process. Try to find an orientation as close as possible to perpendicular to the neck joint face.

4) Pray.

5) Drill holes large enough for the machine scews, through the body and neck. Quadruple-check the drilling depth first! Nobody likes holes in their fretboard, right? Careful jigging should allow me to get all the holes parallel. And I'll have reference/pilot holes for the subsequent neck drilling (see step 5). Actually, before leaving each location, I may as well forstner the wells for the ferrules. Swap bits for that. Swap back when done. Repeat the whole thing x3.

6) Remove the neck from the body. Pick a neck hole. Mounting the drill bit that was previously engaged to drill through both units, jimmy and wiggle the neck into the correct orientation and clamp it there. Try not to snap off the drill bit along the way. Switch bits and drill for the insert. Countersink that hole a tad. Repeat x3.

7) Tap the holes for the inserts. Wax/soap an insert. Using a jig to keep the tap square, tap 'er in. Slowly. Gently. Carefully. Repeat x3. Any recommendations on whether I should do it by hand, or if I'd be better off using the drill press as an arbor?

8) Measure for machine screw lengths. Cut 'em to suit. Label them somehow, so I don't get mixed up.

9) Dry fit neck. Bolt it on with machine screws and ferrules.

10) Drink (in either case, success or failure)

Sooo... laughter, corrections, adjustments, feedback, ideas - all are welcome, come one, come all.

It looks as though my body and neck will ship in the foreseeable future, and I'd like to get myself straightened out for the process of mounting the neck. I plan to use threaded inserts. Yes, I've read the relevant threads here, and they've been a big help. (special thanks to Cagey for all his pointers, esp. http://unofficialwarmoth.com/index.php?topic=22486.msg333429#msg333429).

I have a full-sized drill press, and know how to use it. And various doo-dads for positioning and fixing, including an XY vise. And I have the threaded inserts on hand - both the EZlok ones as well as the larger-threaded sharp ones. And I have the ferrules and machine screws, drill bits (regular, brad point, and forstner), and taps for the EZloks. And soap and wax. And some hard maple stock to practice on. I might be shy on the courage though - but hey, one of our family mottos is "God hates a coward", so I'll be heading in.

So what's my question? Well, I want confirmation and advice on the order of business. Neither the neck nor body will have any holes in them. My biggest concern is getting everything where it should be. So here's my current plan:

1) Pray.

2) Measure, measure, measure, and find the right position for the mounting holes. Narrow enough so that the inserts will have enough clearance from the edge of the neck, and wide enough so that I maximize the strength and stability of the join, without the furrules. Mark locations on body.

3) Dry fit the neck and find some way to keep it there. Creative and careful application of clamps is in order. Neck fit must be 100% correct, and must not move a whisker during the drilling process. Try to find an orientation as close as possible to perpendicular to the neck joint face.

4) Pray.

5) Drill holes large enough for the machine scews, through the body and neck. Quadruple-check the drilling depth first! Nobody likes holes in their fretboard, right? Careful jigging should allow me to get all the holes parallel. And I'll have reference/pilot holes for the subsequent neck drilling (see step 5). Actually, before leaving each location, I may as well forstner the wells for the ferrules. Swap bits for that. Swap back when done. Repeat the whole thing x3.

6) Remove the neck from the body. Pick a neck hole. Mounting the drill bit that was previously engaged to drill through both units, jimmy and wiggle the neck into the correct orientation and clamp it there. Try not to snap off the drill bit along the way. Switch bits and drill for the insert. Countersink that hole a tad. Repeat x3.

7) Tap the holes for the inserts. Wax/soap an insert. Using a jig to keep the tap square, tap 'er in. Slowly. Gently. Carefully. Repeat x3. Any recommendations on whether I should do it by hand, or if I'd be better off using the drill press as an arbor?

8) Measure for machine screw lengths. Cut 'em to suit. Label them somehow, so I don't get mixed up.

9) Dry fit neck. Bolt it on with machine screws and ferrules.

10) Drink (in either case, success or failure)

Sooo... laughter, corrections, adjustments, feedback, ideas - all are welcome, come one, come all.