mycroftxxx

Junior Member

- Messages

- 83

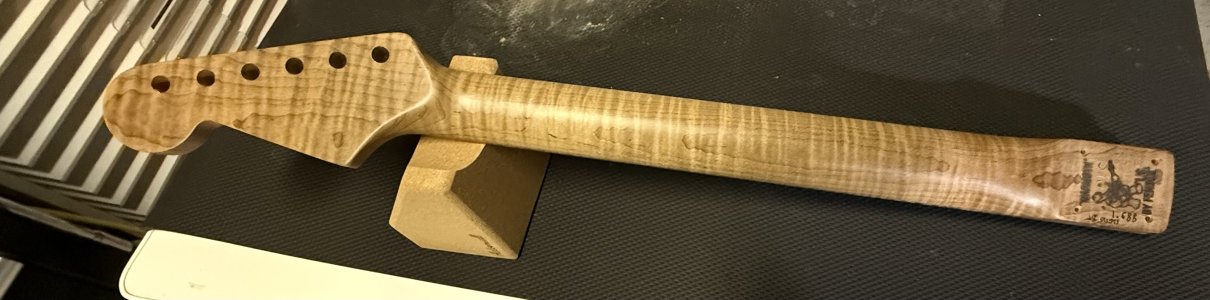

Kicking off a new build today by ordering a fully finished carved top Soloist body (I’m not set up to do paint/dye/etc.); since that will take 4 months or so to get here, I have plenty of time to order the rest of the parts, including a Warmoth neck, but I wanted to get the body on order as soon as possible due to the lead time. Basic specs are: carved top Soloist in alder, right handed, flame maple lam top, three Strat pickup routs, three control knobs plus 5-way switch, battery box, hardtail drilled for the Schaller 415 aka 3D-6 top loader bridge, tiger’s eye dye on the front. Neck will be 22 stainless frets, modern construction, probably roasted flame maple with classic Strat headstock shape, but I have time to tweak these specs since I won’t be ordering the neck for a few weeks.

The intent is, when complete, to be a kind of blues-ish superstrat, with three medium-spicy noiseless single-coil pickups (likely Zexcoils), an active clean boost control, and an active mid-boost control. The two active circuits will be similar to the Fender “Clapton” mid-boost, except I’m not using that one because with the Fender boost, when you turn it on, the clean boost is always active and you only have control over the mid-boost, and I want independent control over both. Right now I’m planning to go with two EMG parts that meet my requirements for the active elements. I might even use EMG parts for everything but the pickups and try out their solderless wiring system.

I’ll keep this updated as I finalize the part selection and start receiving parts and assembling stuff, which will be some weeks down the road, but anyone who wants to comment is welcome of course!

The intent is, when complete, to be a kind of blues-ish superstrat, with three medium-spicy noiseless single-coil pickups (likely Zexcoils), an active clean boost control, and an active mid-boost control. The two active circuits will be similar to the Fender “Clapton” mid-boost, except I’m not using that one because with the Fender boost, when you turn it on, the clean boost is always active and you only have control over the mid-boost, and I want independent control over both. Right now I’m planning to go with two EMG parts that meet my requirements for the active elements. I might even use EMG parts for everything but the pickups and try out their solderless wiring system.

I’ll keep this updated as I finalize the part selection and start receiving parts and assembling stuff, which will be some weeks down the road, but anyone who wants to comment is welcome of course!