mayfly

Epic Member

- Messages

- 9,176

Gentlemen,

For my upcoming birthday, I decided that I should give myself a present. I decided that this should be a little guitar amp that I could use on the front porch just to practice stuff. Nothing fancy, just amplify the signal with good tone.

For those who know me, you'll know this is a bit of a departure as I sold all my amps several years ago when I got into the AxeFX thing. For those who really know me, you'll know that before that I had a tube guitar amplifier business in which I marketed and sold amps that I designed and built from scratch.

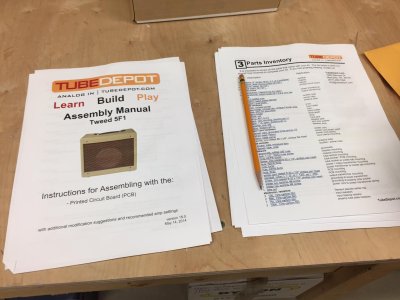

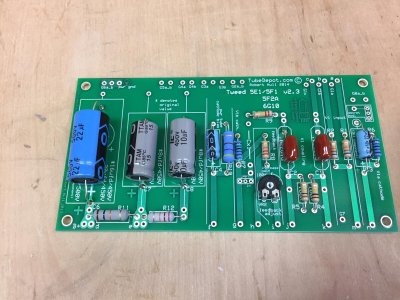

So I decided to build my own. Now, I know how much effort it is to design an amp from scratch, and I didn't want to do that. I also didn't want to be bothered collecting together all the parts. So my options now were kits - but which kit? I didn't want a weber kit, as I didn't want to replace half the parts, I didn't want anyone who used a fish paper eyelette board (I'll reserve my rant against vintage fenders with fish paper boards and how the humidity absorbed into these things starts to conduct over the decades causing all kinds of issues with your vintage fender). I also didn't want a marshall type: too big, even the 18 watters. So this left me with the TubeDepot. Specifically the 'fender champ' kit.

Now, I know how much effort it is to design an amp from scratch, and I didn't want to do that. I also didn't want to be bothered collecting together all the parts. So my options now were kits - but which kit? I didn't want a weber kit, as I didn't want to replace half the parts, I didn't want anyone who used a fish paper eyelette board (I'll reserve my rant against vintage fenders with fish paper boards and how the humidity absorbed into these things starts to conduct over the decades causing all kinds of issues with your vintage fender). I also didn't want a marshall type: too big, even the 18 watters. So this left me with the TubeDepot. Specifically the 'fender champ' kit.

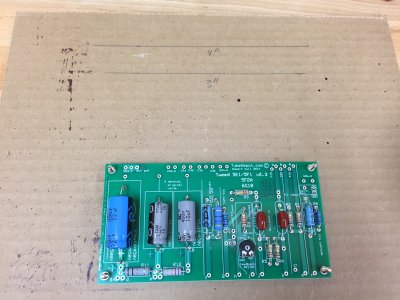

The shipment just arrived: It's a pretty big box for a champ!

For my upcoming birthday, I decided that I should give myself a present. I decided that this should be a little guitar amp that I could use on the front porch just to practice stuff. Nothing fancy, just amplify the signal with good tone.

For those who know me, you'll know this is a bit of a departure as I sold all my amps several years ago when I got into the AxeFX thing. For those who really know me, you'll know that before that I had a tube guitar amplifier business in which I marketed and sold amps that I designed and built from scratch.

So I decided to build my own.

The shipment just arrived: It's a pretty big box for a champ!