Hi there - first post! I am building a guitar based on a template (Garcia style Tiger tribute) with a neck pocket for a s-style bolt-on neck. I have calculated I need about a 2.3 degree angle to tilt the neck back for proper string height over the TOM bridge, and I built a jig for this purpose.

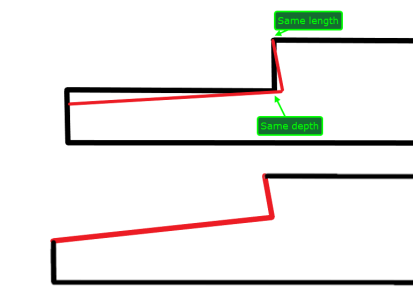

My question is, I can see how to rout the angle in the bottom of the neck pocket, but I am unsure how to get the complementary angle in the vertical face of the neck pocket where the heel end meets it. If I disregard it, then the pocket will no longer be perpendicular between those 2 faces. I don't see an obvious way to rout this surface since my pattern bit is shorter than the 5/8" height of the pocket. Does my question make sense and can anyone advise? Or is ~2 degrees not enough to worry about? Come to think of it, I'd face the same issue if I used a shim for the same purpose.

Thoughts? My project is coming along nicely - I'll start a build thread when I get a little further along. Using a Warmoth Hombre neck which is a real work of art.

Thanks! Adam

My question is, I can see how to rout the angle in the bottom of the neck pocket, but I am unsure how to get the complementary angle in the vertical face of the neck pocket where the heel end meets it. If I disregard it, then the pocket will no longer be perpendicular between those 2 faces. I don't see an obvious way to rout this surface since my pattern bit is shorter than the 5/8" height of the pocket. Does my question make sense and can anyone advise? Or is ~2 degrees not enough to worry about? Come to think of it, I'd face the same issue if I used a shim for the same purpose.

Thoughts? My project is coming along nicely - I'll start a build thread when I get a little further along. Using a Warmoth Hombre neck which is a real work of art.

Thanks! Adam