Megatron

Junior Member

- Messages

- 92

Hello! First time caller, long time listener.

I've just started collecting all the parts for a fiesta red warmoth strat build.

I'll start by saying that I heard about warmoth from darryl braun's youtube channel. He's done quite a few builds, and that's really what inspired me to take the plunge into a custom build. I've watched quite a few videos from braun, phil mcknight, the warmoth channel and a few full warmoth builds from random channels, and they all pushed me in this direction. Looks like warmoth does all the complicated work in terms of dimensions, angles and finishes, with the simpler assembly portion finalized by me.

I started my journey playing an Ibanez prestige RG with a hard tail. I loved that guitar, but the neck was too thin and too flat at the top frets and resonance was a bit sterile, even when played acoustically. Which makes sense because the fast decay is good for metal. I then got a Gibson les paul, and that thing has the classic rock sound I love, but the neck is quite chunky, and I did miss the slightly wider fret spacing of a 25.5" scale length.

This brings me to my custom build:

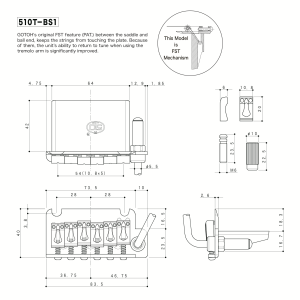

What I'm putting together is a bit of a hybrid axe. I'm constructing a classical strat body with a stratosphere loaded pickguard packing fender yosemite single-coils, which should give me the more vintage single-coil sound I'm seeking in this build. But the rest of the guitar is inspired by the suhr modern superstrat: Body is roasted alder, roasted maple neck with stainless steel jumbo frets, compound 10-16" radius, Gotoh 510T-BS1 trem with brass saddles and an angled steel block, Gotoh HAP-M staggered and locking posts so I can forgo a string tree.

I'm hoping that the angled steel block of the 510T allows me to dive with a floated trem - darryl braun has an excellent video on the floating setup.

Any pointers from the community? I'm mostly nervous about the stud/insert installation and the drilling of pilot holes into roasted wood. I've got screw wax to lubricate screws. Also, any thoughts on floating the 510T in the absence of a recessed trem cavity (as on the floyd routes or the Ibanez AZ's).

I'll post updates when the body and neck arrive. Pumped!

I've just started collecting all the parts for a fiesta red warmoth strat build.

I'll start by saying that I heard about warmoth from darryl braun's youtube channel. He's done quite a few builds, and that's really what inspired me to take the plunge into a custom build. I've watched quite a few videos from braun, phil mcknight, the warmoth channel and a few full warmoth builds from random channels, and they all pushed me in this direction. Looks like warmoth does all the complicated work in terms of dimensions, angles and finishes, with the simpler assembly portion finalized by me.

I started my journey playing an Ibanez prestige RG with a hard tail. I loved that guitar, but the neck was too thin and too flat at the top frets and resonance was a bit sterile, even when played acoustically. Which makes sense because the fast decay is good for metal. I then got a Gibson les paul, and that thing has the classic rock sound I love, but the neck is quite chunky, and I did miss the slightly wider fret spacing of a 25.5" scale length.

This brings me to my custom build:

What I'm putting together is a bit of a hybrid axe. I'm constructing a classical strat body with a stratosphere loaded pickguard packing fender yosemite single-coils, which should give me the more vintage single-coil sound I'm seeking in this build. But the rest of the guitar is inspired by the suhr modern superstrat: Body is roasted alder, roasted maple neck with stainless steel jumbo frets, compound 10-16" radius, Gotoh 510T-BS1 trem with brass saddles and an angled steel block, Gotoh HAP-M staggered and locking posts so I can forgo a string tree.

I'm hoping that the angled steel block of the 510T allows me to dive with a floated trem - darryl braun has an excellent video on the floating setup.

Any pointers from the community? I'm mostly nervous about the stud/insert installation and the drilling of pilot holes into roasted wood. I've got screw wax to lubricate screws. Also, any thoughts on floating the 510T in the absence of a recessed trem cavity (as on the floyd routes or the Ibanez AZ's).

I'll post updates when the body and neck arrive. Pumped!