Dano

Junior Member

- Messages

- 105

I have recently become aware of how helpful these build threads can be and promised myself I would post mine to try to be a better part of the community here at Warmoth! This post is after the fact and I had no idea I would be attempting to document anything from this build. With that in mind, I hope there is something of use to someone, if nothing other than the fact that it is easy to mess up and difficult to recover!

I have two grandsons and I decided to build them each a guitar. I just finished them, so I am going to post a few pics and descriptions of what I did along the way, as best I recall.

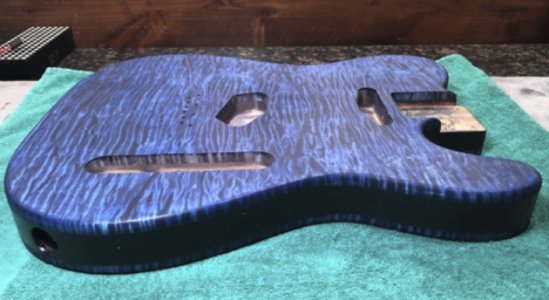

I happened to run across a really nice body on eBay that looked fantastic. This body is very unusual in that it has a 3/8” Flame Maple laminate on both the top and the back. It was unfinished and I have very little experience in this area. I have only done finish work on Rosewood with Tru-Oil. I had never done a stained guitar and this is what it turned out to be. It came out nice, but this endeavor turned out to be quite a bit more challenging than my previous projects.

This guitar was intended for my 13 year old grandson and he is fond of really flashy stuff and blue is his favorite color. It is a beautiful specimen of flame and my objective going in was to show that flame off and try not mess it up too badly. That objective was ultimately realized, but not without some hurdles to clear in the process.

Here are a few pictures of the guitar as I received it:

I have two grandsons and I decided to build them each a guitar. I just finished them, so I am going to post a few pics and descriptions of what I did along the way, as best I recall.

I happened to run across a really nice body on eBay that looked fantastic. This body is very unusual in that it has a 3/8” Flame Maple laminate on both the top and the back. It was unfinished and I have very little experience in this area. I have only done finish work on Rosewood with Tru-Oil. I had never done a stained guitar and this is what it turned out to be. It came out nice, but this endeavor turned out to be quite a bit more challenging than my previous projects.

This guitar was intended for my 13 year old grandson and he is fond of really flashy stuff and blue is his favorite color. It is a beautiful specimen of flame and my objective going in was to show that flame off and try not mess it up too badly. That objective was ultimately realized, but not without some hurdles to clear in the process.

Here are a few pictures of the guitar as I received it: