bruzanhd

Senior Member

- Messages

- 215

The goal for this build was to be a very 80s inspired single humbucker, with the #1 concern that it had a decked floyd (resting against the body with no pull-up). I wanted to document this mostly for the sake of the floyd setup because hopefully if anyone else runs into this issue then they won't have to stress about it like I did. I will get into why this setup is such a challenge to achieve further into this thread. With that said the said here is the spec sheet:

Neck:

Construction

Modern

Shaft Wood

Quartersawn Maple

Fretboard Wood

Ebony

Unique Choice

No, Warmoth can choose for me.

Nut Width

1-11/16" (43mm) - Modern Medium

Right / Left Handed

Right-Handed

Neck Back Profile

Standard Thin

Fretboard Radius

10" - 16" Compound

Number of Frets

22

Scallops

None

Binding

None

Fret Size & Material

SS6100 - Jumbo (Stainless)

Tuner Hole Size

Gotoh/Grover (13/32" - 11/32")

Inlay Shape

Standard Dots

Inlay Material

Cream

Side Dots

White Side Dots

String Nut

R4 Floyd Prep w/ Mounting Holes

Mounting Holes

Standard 4-Bolt

Neck Heel Shape

Strat® Shape

Finish

Clear Satin Nitro (Maple/Non-Maple)

Body:

Construction

Solid

Core Wood

Alder

Lam Top Wood

No Lam Top

Right / Left Handed

Right-Handed

Control Cavity

Rear Rout

Neck Pickup Rout

None

Middle Pickup Rout

None

Bridge Pickup Rout

Humbucker (Wood Mount)

Controls

Volume 1

Jack Rout

7/8" (22mm) Side Jack Hole

Bridge Rout Type

Tremolo

Bridge Rout

Floyd Rose (Angled Pocket)

Would you like Warmoth to install the bridge studs?

No

Mounting Holes

Standard 4-Bolt

Neck Pocket Shape

Strat®

Body Contours

Forearm Contour, Tummy Cut

Battery Box

None

Paint Category

Solid

Top Color

Alpine White

Back Color

Alpine White

Satin or Gloss

Gloss

Hardware:

Gotoh tuners

Floyd rose 1984 reissue

Duncan JB with alnico 2 swap

500k CTS pot

D-tuna

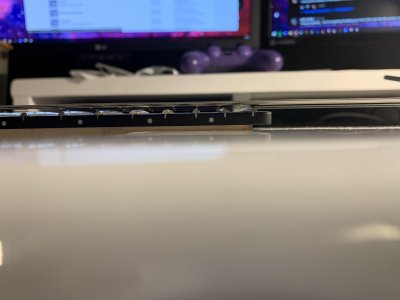

Now, the setup. By default, the non recessed floyd comes with an angled neck pocket. The angle they use is 1deg. With these parameters, your bridge will float ~4mm above the body. No good. In order to prevent this issue you could specially order your body with a non angled neck pocket, but a) I did not know that was possible at the time of order, and b) you will absolutely have to shim the neck for this, (albeit the angle is very small at roughly 0.20-0.35deg. Since I already had the 1deg angle, I decided to reduce the angle. There is a number of ways you can do this; router, hand plan, sand paper, dremel, chisels. Whatever you are most confident with is best. I chose sandpaper and used a very wide chisel to act as a plane to nock down high spots at the end of the sanding process.

Procedure:

First you should have a rough idea of how much material you are actually going to remove. Simple trigonometry will help you make this estimate.

Neck pocket length (heel side to headstock side) = 76.2mm

Depending on your body wood, different grits of sandpaper may be better or worse. Harder woods will benefit from a grittier paper, simply because it wont take you as long this way. Since my body was swamp ash which is a harder wood, I used 80 grit paper and that worked very well. With this method it will take a serious amount of elbow grease to actually make any noticeable change in angle. In this regard this method is safest since it takes a lot of time to make even minute changes to neck angle.

Use a good straight edge and check for high and low spots frequently. Use pencil graphite to lightly shade all high spots and then lower them with the sand paper,again this will take time and you should ideally check the neck to body fit quite frequently. When checking the neck angle you must check under full tension with the neck bolted on properly. Since the neck screws will actually compress the wood a very small amount (<0.6mm) full tension is important. After all was said and done I estimate my neck angle to be in the neighborhood of 0.23-0.33deg which is what I expected based on my trigonometry. I have included a picture where I derive this numbers. (please note that the measurements are only rough, since these numbers are so small, getting a perfect measurement is not realistic.)

If you are a really talented builder, a flat neck pocket with a microtilt adjustment would actually be the perfect way to build a guitar like this.

Better pictures will come when I can borrow a camera

Neck:

Construction

Modern

Shaft Wood

Quartersawn Maple

Fretboard Wood

Ebony

Unique Choice

No, Warmoth can choose for me.

Nut Width

1-11/16" (43mm) - Modern Medium

Right / Left Handed

Right-Handed

Neck Back Profile

Standard Thin

Fretboard Radius

10" - 16" Compound

Number of Frets

22

Scallops

None

Binding

None

Fret Size & Material

SS6100 - Jumbo (Stainless)

Tuner Hole Size

Gotoh/Grover (13/32" - 11/32")

Inlay Shape

Standard Dots

Inlay Material

Cream

Side Dots

White Side Dots

String Nut

R4 Floyd Prep w/ Mounting Holes

Mounting Holes

Standard 4-Bolt

Neck Heel Shape

Strat® Shape

Finish

Clear Satin Nitro (Maple/Non-Maple)

Body:

Construction

Solid

Core Wood

Alder

Lam Top Wood

No Lam Top

Right / Left Handed

Right-Handed

Control Cavity

Rear Rout

Neck Pickup Rout

None

Middle Pickup Rout

None

Bridge Pickup Rout

Humbucker (Wood Mount)

Controls

Volume 1

Jack Rout

7/8" (22mm) Side Jack Hole

Bridge Rout Type

Tremolo

Bridge Rout

Floyd Rose (Angled Pocket)

Would you like Warmoth to install the bridge studs?

No

Mounting Holes

Standard 4-Bolt

Neck Pocket Shape

Strat®

Body Contours

Forearm Contour, Tummy Cut

Battery Box

None

Paint Category

Solid

Top Color

Alpine White

Back Color

Alpine White

Satin or Gloss

Gloss

Hardware:

Gotoh tuners

Floyd rose 1984 reissue

Duncan JB with alnico 2 swap

500k CTS pot

D-tuna

Now, the setup. By default, the non recessed floyd comes with an angled neck pocket. The angle they use is 1deg. With these parameters, your bridge will float ~4mm above the body. No good. In order to prevent this issue you could specially order your body with a non angled neck pocket, but a) I did not know that was possible at the time of order, and b) you will absolutely have to shim the neck for this, (albeit the angle is very small at roughly 0.20-0.35deg. Since I already had the 1deg angle, I decided to reduce the angle. There is a number of ways you can do this; router, hand plan, sand paper, dremel, chisels. Whatever you are most confident with is best. I chose sandpaper and used a very wide chisel to act as a plane to nock down high spots at the end of the sanding process.

Procedure:

First you should have a rough idea of how much material you are actually going to remove. Simple trigonometry will help you make this estimate.

Neck pocket length (heel side to headstock side) = 76.2mm

Depending on your body wood, different grits of sandpaper may be better or worse. Harder woods will benefit from a grittier paper, simply because it wont take you as long this way. Since my body was swamp ash which is a harder wood, I used 80 grit paper and that worked very well. With this method it will take a serious amount of elbow grease to actually make any noticeable change in angle. In this regard this method is safest since it takes a lot of time to make even minute changes to neck angle.

Use a good straight edge and check for high and low spots frequently. Use pencil graphite to lightly shade all high spots and then lower them with the sand paper,again this will take time and you should ideally check the neck to body fit quite frequently. When checking the neck angle you must check under full tension with the neck bolted on properly. Since the neck screws will actually compress the wood a very small amount (<0.6mm) full tension is important. After all was said and done I estimate my neck angle to be in the neighborhood of 0.23-0.33deg which is what I expected based on my trigonometry. I have included a picture where I derive this numbers. (please note that the measurements are only rough, since these numbers are so small, getting a perfect measurement is not realistic.)

If you are a really talented builder, a flat neck pocket with a microtilt adjustment would actually be the perfect way to build a guitar like this.

Better pictures will come when I can borrow a camera