gdgross

Junior Member

- Messages

- 41

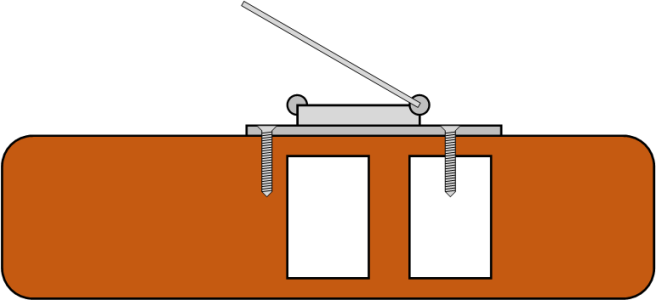

Hi all, have a chambered Jazzmaster body on which I’m installing a bigsby B5. (Had warmoth rout for a tune o Matic bridge and angled neck pocket)

I spaced the Trem and drilled pilot holes for the 4 mounting screws on the bigsby. 3 out of 4 of them are over the chambered areas, I think, as they don’t feel like solid drills.

So what are my options now? The drill holes into the chambers make me nervous about holding the Trem in place with the force of the strings ( and I tend to use heavier strings, like 10s on fenders or heavier maybe)

I had the thought to drill the three holes out bigger and install/glue short dowels maybe ½” in diameter or so, flush against the top and just re drill the holes?

Any other ideas?

I spaced the Trem and drilled pilot holes for the 4 mounting screws on the bigsby. 3 out of 4 of them are over the chambered areas, I think, as they don’t feel like solid drills.

So what are my options now? The drill holes into the chambers make me nervous about holding the Trem in place with the force of the strings ( and I tend to use heavier strings, like 10s on fenders or heavier maybe)

I had the thought to drill the three holes out bigger and install/glue short dowels maybe ½” in diameter or so, flush against the top and just re drill the holes?

Any other ideas?