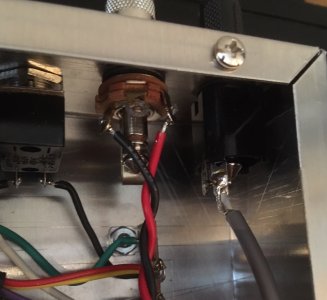

Since the neck volume wasn't involved in any of the funny business, I loaded it into the control cavity on its own and made up the pickup and switch connections. (Actually, the switch wire on the middle lug isn't soldered yet as the capacitor will be going there. That will be fun...) The wire from the grounded lug will join the pot case grounds when the rest of them get loaded in. The red wire on the left is the string ground. I joined it with the wire for the neck pickup cover/mounting plate ground and will ground it on the output jack.

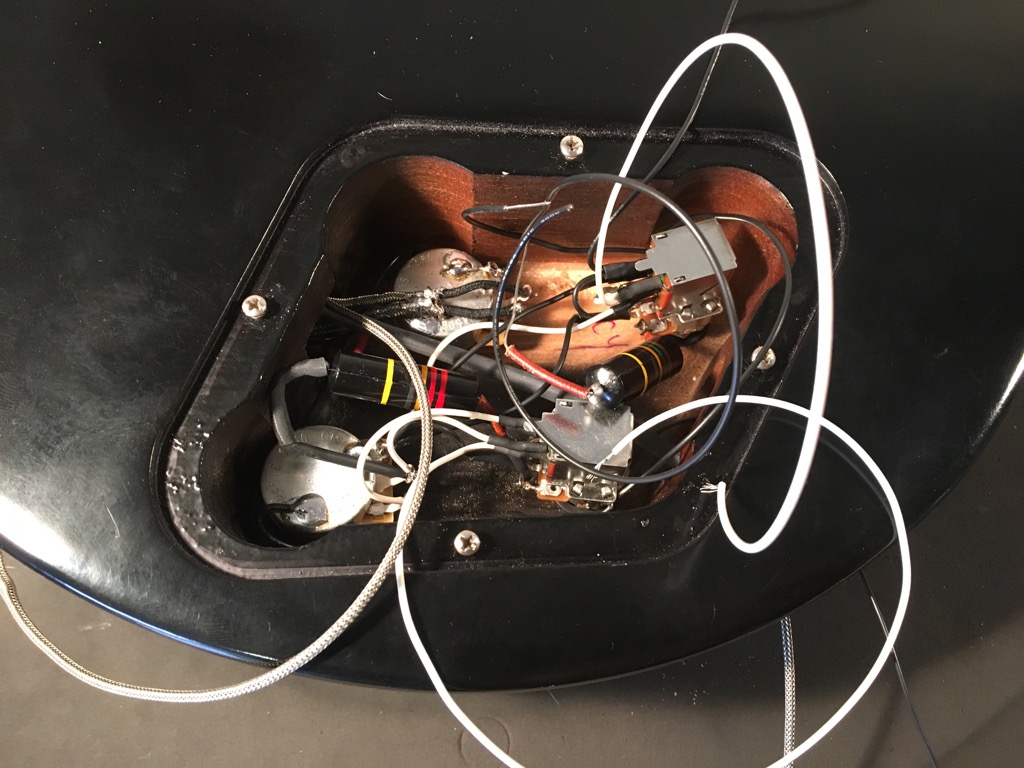

And in with the rest of the guts... egad!

At this point I've just got a few connections to make. The neck tone cap to the volume pot, the neck volume pot ground to the rest of the grounds, the output of the bridge control bypass switch to the selector switch, and the hot and ground for the output jack. After making those connections and cleaning things up, this control cavity looks almost like you could bring it out in public without being embarrassed.

The two wires exiting the cavity are for the bridge pickup hot and ground..

I hooked the old bridge pickup back up with alligator clip leads just to verify that everything worked and, because why not, there was exactly zero output. I traced the issue down to a single sliver of braided shielding making contact with the tip of the output jack. I wouldn'ta thunk it possible with all the heat shrink in there, but there it was. Remedied that and proceeded to get a good functional checkout on everything. I'm going to call that a success story.

Old Black sports either gold or amber "Top Hat" or "Bell" style knobs. I think they are amber, but then I see a picture where they look gold, I dunno. I do know that those bell style knobs suck with push/pulls, so we are going to follow function over form and go with standard speed knobs. I tried the amber, two different varieties, and I didn't like either of them. They just did not fit aesthetically. The gold ones on the other hand look quite sharp. I made an Executive Decision.

For now that's about as far as I can go. Well, almost. I broke a corner of the plastic jack plate when I was re-installing it so I will probably track down a proper metal replacement. Something to add to my solder-lug-washer order!