RiffWildly

Newbie

- Messages

- 14

Hi there, and welcome me, my first post. I hope this isn't too stupid of a question:

I have a compound radius (10" - 16") neck on the way, to be fitted to a Gretsch Billy-Bo style body. The neck pocket rout is a standard Strat rout, and (hopefully) the neck will slide right in.

So, Question Part One: What would be the correct, ideal bridge radius for this neck? The way I figure it, the bridge radius would want to be around 18".

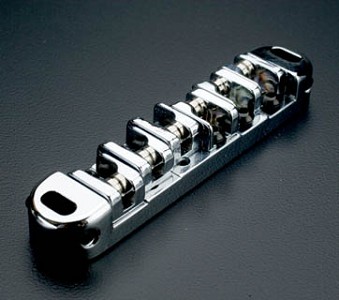

I also want to use a Bigsby on this guitar, and I'd like to use a roller bridge, but if there is such a thing as a roller bridge with an 18" radius, I have not found it. I don't want to use a Tele-style bridge with 3 saddles, either. So, Question Part Two: what other options do I have? I have a Schaller roller bridge with a 14" radius, but it's obviously not going to be ideal. Ideas appreciated!

I have a compound radius (10" - 16") neck on the way, to be fitted to a Gretsch Billy-Bo style body. The neck pocket rout is a standard Strat rout, and (hopefully) the neck will slide right in.

So, Question Part One: What would be the correct, ideal bridge radius for this neck? The way I figure it, the bridge radius would want to be around 18".

I also want to use a Bigsby on this guitar, and I'd like to use a roller bridge, but if there is such a thing as a roller bridge with an 18" radius, I have not found it. I don't want to use a Tele-style bridge with 3 saddles, either. So, Question Part Two: what other options do I have? I have a Schaller roller bridge with a 14" radius, but it's obviously not going to be ideal. Ideas appreciated!