You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What the hell am I going to do with this thing?

- Thread starter mayfly

- Start date

rockandroller

Senior Member

- Messages

- 650

Are you going to use an actual Rickenbacker-style bridge and tailpiece setup? Everything you do with the neck joint should be based on the height of that incoming bridge...

stratamania

Mythical Status

- Messages

- 12,322

Ah, decisions. I am sure you will sort it out.Sure! But then there would be a little notch where the body meets the neck on the bass side. I might be able to get 1/8" that way, or maybe more since I plan to cut the heel down on the bottom a bit.

This brings us to the second problem: The heel of the neck is not parallel to the fretboard; it's angled down at a typical gibson neck angle. Ricks have their necks flat WRT the body ... should I do the same here or angle it? Hmmmm....

mayfly

Epic Member

- Messages

- 9,187

OK! I did some investigation and Guitar Fetish makes a pile of rick-type pickups. They are 1/2" high, so with some calculations I determined the appropriate height of the fingerboard off the body. From that I calculated how much to cut off from the neck heel:

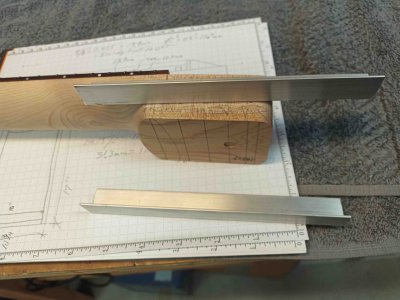

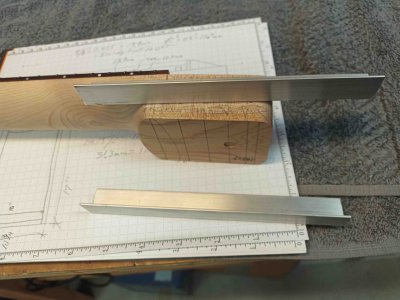

I'm thinking I'll cut the heel first, then notch the top once I make sure the geometry works. Now how to cut that heel! A band saw or a table saw would be the perfect solution, but I don't have either. I thought about using a router, but that would require some fancy-ass jig because of the strange geometry. Currently I'm thinking I'll cut it with a Japanese hand saw. Now, I'm not that great with the saw, so I need some kind of guide to make sure I don't go overboard. I'm exploring aluminum L-brackets double sided taped to it on either side...

I'm thinking I'll cut the heel first, then notch the top once I make sure the geometry works. Now how to cut that heel! A band saw or a table saw would be the perfect solution, but I don't have either. I thought about using a router, but that would require some fancy-ass jig because of the strange geometry. Currently I'm thinking I'll cut it with a Japanese hand saw. Now, I'm not that great with the saw, so I need some kind of guide to make sure I don't go overboard. I'm exploring aluminum L-brackets double sided taped to it on either side...

Hodgo

Experienced Member

- Messages

- 1,138

Filler and paint make me the carpenter I ain’t!This is going to end badly.

Spud

Master Member

- Messages

- 3,031

Putty's your buddy!Filler and paint make me the carpenter I ain’t!

mayfly

Epic Member

- Messages

- 9,187

Update time. I had some time on vacation to think about this little problem, and during that time I remembered something about a drill press mounted planer. Specifically this thing:

So despite the trade mashup, I ordered one. While I was waiting, I came up with a jig to hold the neck the way I wanted:

The vice ensures that the work is parallel to the cutter, and the elastic arrangement at the headstock end allows tilt adjustment.

The arrangement actually worked!

I started out making quite large cuts, but then settled down to very fine increments. I did this by leaving the drill press table where it was and adding old business cards under the neck to bring it up a c*nt hair or two. I stopped early to give myself some breathing room; the result is very very nice:

Onward!

So despite the trade mashup, I ordered one. While I was waiting, I came up with a jig to hold the neck the way I wanted:

The vice ensures that the work is parallel to the cutter, and the elastic arrangement at the headstock end allows tilt adjustment.

The arrangement actually worked!

I started out making quite large cuts, but then settled down to very fine increments. I did this by leaving the drill press table where it was and adding old business cards under the neck to bring it up a c*nt hair or two. I stopped early to give myself some breathing room; the result is very very nice:

Onward!

mayfly

Epic Member

- Messages

- 9,187

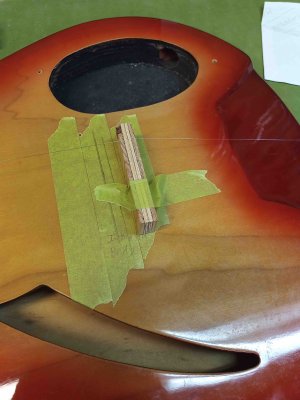

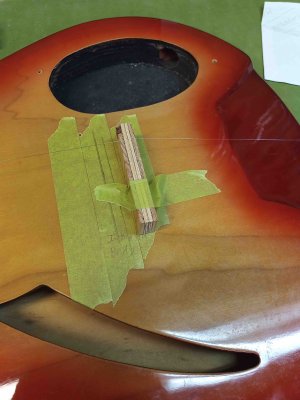

Update: Testing scale length to make sure I'm not way off.

Like that tailpiece?

Headstock looks a little Phat. Or maybe it's those huge gotoh 510s that are on there (that I just happened to have lying around).

Better too Phat than too Phin....

Body to neck joint looks pretty good. The little crack is just in the finish.... I hope....

Like my bridge? Nut is almost as good...

Like that tailpiece?

Headstock looks a little Phat. Or maybe it's those huge gotoh 510s that are on there (that I just happened to have lying around).

Better too Phat than too Phin....

Body to neck joint looks pretty good. The little crack is just in the finish.... I hope....

Like my bridge? Nut is almost as good...

TonyFlyingSquirrel

Master Member

- Messages

- 4,749

Update time. I had some time on vacation to think about this little problem, and during that time I remembered something about a drill press mounted planer. Specifically this thing:

So despite the trade mashup, I ordered one. While I was waiting, I came up with a jig to hold the neck the way I wanted:

View attachment 66267

The vice ensures that the work is parallel to the cutter, and the elastic arrangement at the headstock end allows tilt adjustment.

View attachment 66268

The arrangement actually worked!

View attachment 66269

I started out making quite large cuts, but then settled down to very fine increments. I did this by leaving the drill press table where it was and adding old business cards under the neck to bring it up a c*nt hair or two. I stopped early to give myself some breathing room; the result is very very nice:

View attachment 66270

Onward!

This is the way!

mayfly

Epic Member

- Messages

- 9,187

Yep. From my experience I can highly recommend it.I was thinking the same thing, that drill press thingy is brilliant!

sdeeg

Junior Member

- Messages

- 92

I was thinking the same thing, that drill press thingy is brilliant!

I love the Safe-T-Plane! So simple and so useful. Definitely a high value to cost ratio tool.Yep. From my experience I can highly recommend it.

Project looks like it's coming along well. Looking forward to seeing it when it's done.

Similar threads

- Replies

- 15

- Views

- 711

- Replies

- 22

- Views

- 4K

- Replies

- 0

- Views

- 988