And there's many ways to skin a cat, I'm not in the cat-skinning business where time is money - aren't hobbies supposed to take time? ???

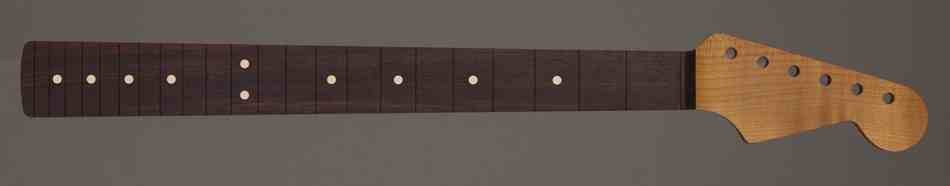

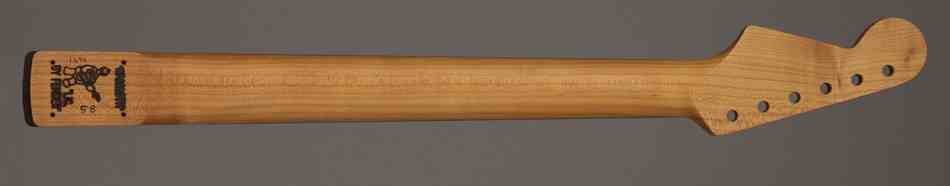

I had a good bit of experience in finishing metal with abrasives, and I have come to do just about ALL the steps with varying grits of the gray wet/dry paper. I do use one of the stainless steel fret masks from Stewie, but the slot never seemed to have much correspondence to what I was trying to protect, so I just stuck a handle on it.

I wrap 320, 400, 600 and 1500 grit paper around a Gibson-sized nut blank with a little groove in it, and by holding the stainless thing against the fret corner I'm working on, it CAN'T eat wood... tape and the Optivisor are most prudent, too.

Shrapnel control is prudent too, especially around already-finished pieces, you really need to think about where your castoff is going before it starts going there.

I have recently seen more and more uses of abrasive papers in knife-sharpening systems, machining procedures etc., the papers really have improved in the last 20 years to the point they'll do certain things better than toothed files. I would have to do an awful lot of necks to justify a $90 diamond file when I can do the same thing with $2 worth of sandpaper.