civilaggie06

Newbie

- Messages

- 24

Hey everyone,

I am a first time builder and am running into things bordering on the NEWB territory.

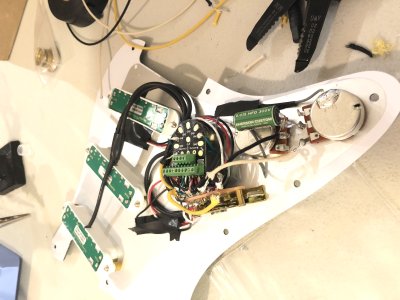

I was installing the following Gotoh tuners.http://www.stewmac.com/Hardware_and_Parts/Tuning_Machines/Solid_Peghead_Guitar_Tuning_Machines/Gotoh_Magnum_Lock_Trad_6_In_Line_Tuners.html

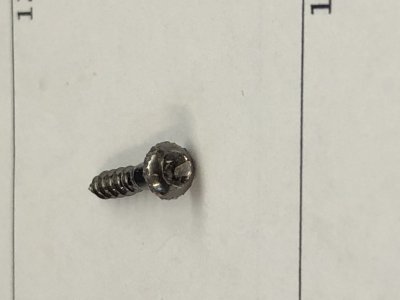

After lining everything up and boring the holes for the screws I installed 3 tuners successfully. Got to the last 3 and I managed to strip the screws .

My question is if you had to replace the screws that come with tuners you buy where can you pick up just the screws without having to buy another whole set of the Tuners?

I tried Lowes and Home Depot and the screws sizes appear to be too big.

From what I can tell the length of the screw is about 12 mm and the thread length is 2.4mm

Any help or suggestions anyone can provide is most appreciated.

Best regards,

Sam Y.

I am a first time builder and am running into things bordering on the NEWB territory.

I was installing the following Gotoh tuners.http://www.stewmac.com/Hardware_and_Parts/Tuning_Machines/Solid_Peghead_Guitar_Tuning_Machines/Gotoh_Magnum_Lock_Trad_6_In_Line_Tuners.html

After lining everything up and boring the holes for the screws I installed 3 tuners successfully. Got to the last 3 and I managed to strip the screws .

My question is if you had to replace the screws that come with tuners you buy where can you pick up just the screws without having to buy another whole set of the Tuners?

I tried Lowes and Home Depot and the screws sizes appear to be too big.

From what I can tell the length of the screw is about 12 mm and the thread length is 2.4mm

Any help or suggestions anyone can provide is most appreciated.

Best regards,

Sam Y.