jay4321

Hero Member

- Messages

- 1,303

What I can say for sure is that this is a real chore.

On a normal job with my preferred tools I can crown a leveled fret into shape in 20 seconds or less, both sides. Not counting sanding and the rest, just overall shaping. My z-file is about 5-6 passes, flip it over and 5-6 passes, and done. I just need to keep generally straight, the file does most of the work, and I'm looking to take off as little fret material as is needed.

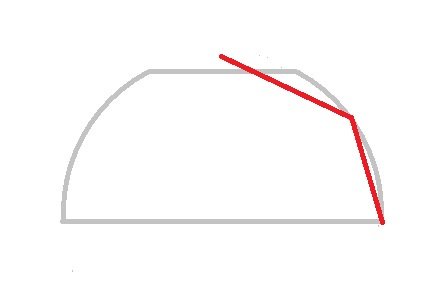

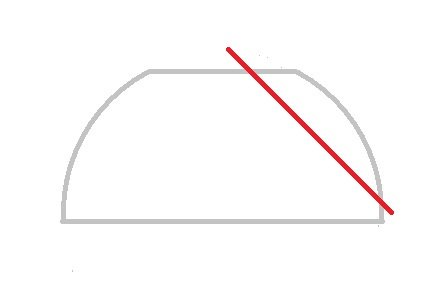

Your job, the opposite is true. I'm intentionally removing metal by hand, and need a lot more skill and control. It took a decent while to get that far and I'd say it's not much more than half of the work. Over a 22 fret guitar you're talking hours of labor-intensive work. And this was just a common nickel fret, not stainless steel.

Maybe a dremel with some kind of mini-angle grinder or chamfer bit. I would at least finish with a hard 45-degree sanding block and expect to need a small size one with the high frets.

An experienced luthier might have a better way to get there but they're doing with hand files expect ridiculous money.

On a normal job with my preferred tools I can crown a leveled fret into shape in 20 seconds or less, both sides. Not counting sanding and the rest, just overall shaping. My z-file is about 5-6 passes, flip it over and 5-6 passes, and done. I just need to keep generally straight, the file does most of the work, and I'm looking to take off as little fret material as is needed.

Your job, the opposite is true. I'm intentionally removing metal by hand, and need a lot more skill and control. It took a decent while to get that far and I'd say it's not much more than half of the work. Over a 22 fret guitar you're talking hours of labor-intensive work. And this was just a common nickel fret, not stainless steel.

Maybe a dremel with some kind of mini-angle grinder or chamfer bit. I would at least finish with a hard 45-degree sanding block and expect to need a small size one with the high frets.

An experienced luthier might have a better way to get there but they're doing with hand files expect ridiculous money.