Hello everybody!

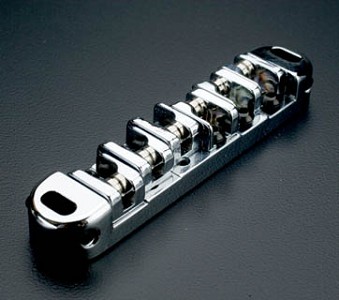

I'm planning to build a Custom Thinline Tele and i wanted to put a Bigsby b-5 horseshoe vibrato on it, or a similar cheap knockoff.

Now the problem is I listened to some Teles with a Bisgby on them and i noticed that somehow the vibrato subtly changed the attack and the twang of the guitar. Then i realized that Bisgby types of vibratos are stringed to the vibrato bar, not through the body, hence the change in sound.

So i was wondering would i be able to string the guitar through the body's ferrules, then through the vibrato and finally trough the nut?

Would the strings be long enough?

Would it function properly?

Thanks guys.

I'm planning to build a Custom Thinline Tele and i wanted to put a Bigsby b-5 horseshoe vibrato on it, or a similar cheap knockoff.

Now the problem is I listened to some Teles with a Bisgby on them and i noticed that somehow the vibrato subtly changed the attack and the twang of the guitar. Then i realized that Bisgby types of vibratos are stringed to the vibrato bar, not through the body, hence the change in sound.

So i was wondering would i be able to string the guitar through the body's ferrules, then through the vibrato and finally trough the nut?

Would the strings be long enough?

Would it function properly?

Thanks guys.