NoOne

Newbie

- Messages

- 10

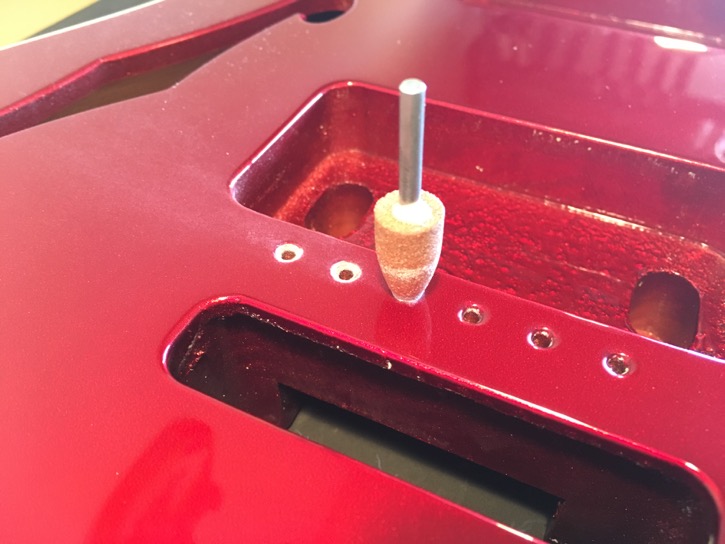

I started installation on my first Warmoth yesterday, and drilled my first holes for the tremolo cover. I noticed today that the satin finish around those holes is coming apart. You can see it am the imgur link

https://imgur.com/9o6Ixdy

Was I running my drill to slow? I was nervous my bit would wander so I started it slower than full speed. If I start it faster would it prevent this? What do I need to do for the pickguard, jack plate, and strap drills to prevent this?

Also, to keep them from spreading, can I cover them with super glue? Not the best looking, but it's on the back and covered. I don't want that propogating.

Thanks for any help!

https://imgur.com/9o6Ixdy

Was I running my drill to slow? I was nervous my bit would wander so I started it slower than full speed. If I start it faster would it prevent this? What do I need to do for the pickguard, jack plate, and strap drills to prevent this?

Also, to keep them from spreading, can I cover them with super glue? Not the best looking, but it's on the back and covered. I don't want that propogating.

Thanks for any help!