Killswitch95

Junior Member

- Messages

- 40

Hello once again,

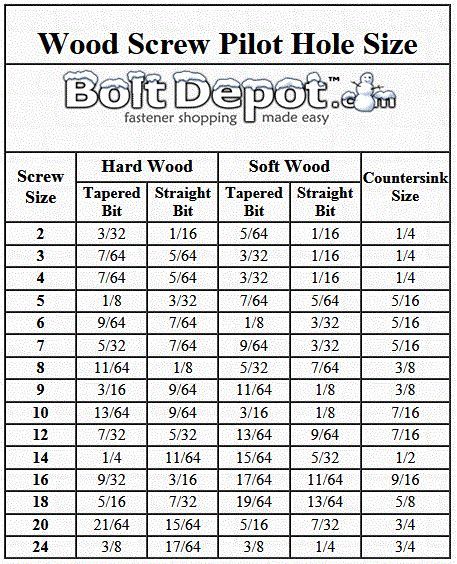

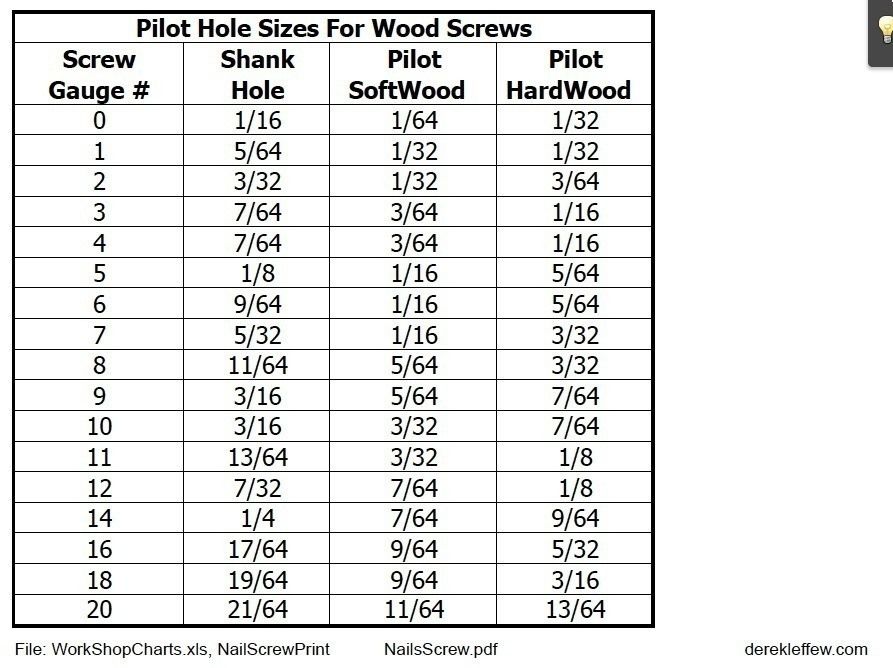

As I'm soon to be drilling multiple holes into my body and neck for various screws I have measured the screw shaft widths, and the hole depth (With the part attached to account for part thickness and not over tighten into the wood to split it).

My question here is, I have a few screws measuring 1.7mm and 1.3mm, and a few others in the -.0mm and -.5mm range, I know my calipers to measure aren't perfect for the job so the .7 and .3mm screws may be a touch smaller in size so can I use a slightly smaller drill bit here and make the pilot hole without worrying about splitting wood? Or is this a job where the hole needs to be 100% exactly the size of the screw shaft so the slightly larger shaft doesn't split wood?

They're not huge screws, but I don't want to risk it my first time out without some advice...

As I'm soon to be drilling multiple holes into my body and neck for various screws I have measured the screw shaft widths, and the hole depth (With the part attached to account for part thickness and not over tighten into the wood to split it).

My question here is, I have a few screws measuring 1.7mm and 1.3mm, and a few others in the -.0mm and -.5mm range, I know my calipers to measure aren't perfect for the job so the .7 and .3mm screws may be a touch smaller in size so can I use a slightly smaller drill bit here and make the pilot hole without worrying about splitting wood? Or is this a job where the hole needs to be 100% exactly the size of the screw shaft so the slightly larger shaft doesn't split wood?

They're not huge screws, but I don't want to risk it my first time out without some advice...