StogiePatriot

Junior Member

- Messages

- 89

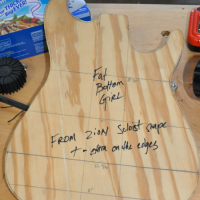

When I meet folks for the first time I have to tell them that I'm a little "touched" - when I get something in my head it just won't stop until I've scratched the itch. Case in point; bought my first body/neck combo from Warmoth and am waiting for the magic boxes.

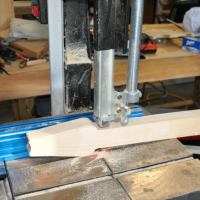

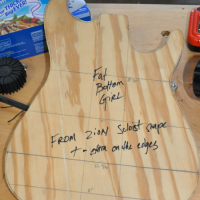

Waiting's never been my strong suit; so I ran down to the local woodworking shop and got tigerwood and quilt maple for a guitar that I'd make while I'm waiting. Probably to sell, but I'm not telling my wife that yet... ;-) In looking at all this wicked wood for a neck through design, I realized that I didn't want to experiment with the expensive woods. So I started to build out the ghetto git today. I started on the neck, with a 3x3 billet of hard maple and cut it up and started to make it happen.

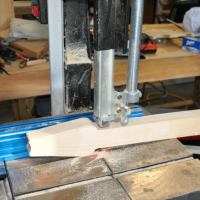

So after the rough shaping and getting a 3x3 block 36" long to a 1.5 inch block of the proper size and shape, I set about making the blank a little more like a neck.

So this is still sans a truss rod, frets and the whole gamut of other stuffins that make up a proper neck, but for a few hours work on a Saturday, I'm not dissatisfied with the result...

Take care and enjoy your Memorial Day weekend (US folk) and your weekend nonetheless.

Waiting's never been my strong suit; so I ran down to the local woodworking shop and got tigerwood and quilt maple for a guitar that I'd make while I'm waiting. Probably to sell, but I'm not telling my wife that yet... ;-) In looking at all this wicked wood for a neck through design, I realized that I didn't want to experiment with the expensive woods. So I started to build out the ghetto git today. I started on the neck, with a 3x3 billet of hard maple and cut it up and started to make it happen.

So after the rough shaping and getting a 3x3 block 36" long to a 1.5 inch block of the proper size and shape, I set about making the blank a little more like a neck.

So this is still sans a truss rod, frets and the whole gamut of other stuffins that make up a proper neck, but for a few hours work on a Saturday, I'm not dissatisfied with the result...

Take care and enjoy your Memorial Day weekend (US folk) and your weekend nonetheless.