PhilHill

Hero Member

- Messages

- 1,653

(While this doesn't have Warmoth parts in it, as they don't make acoustic parts, I felt that it was worth posting for the educational value. Assuming it has educational value........... :dontknow

Greeting's Folks. Got me a new toy that started it up again.

. This is a lot better than my old one. It's actually made to cut hardwood, not just soft pine and it can reduce a piece to 1/8 thick. The old one could only go down to 1/2 inch.

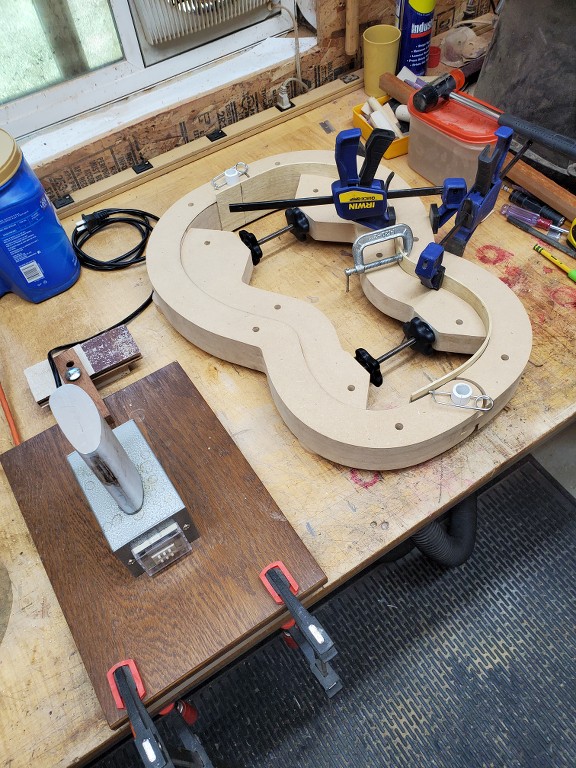

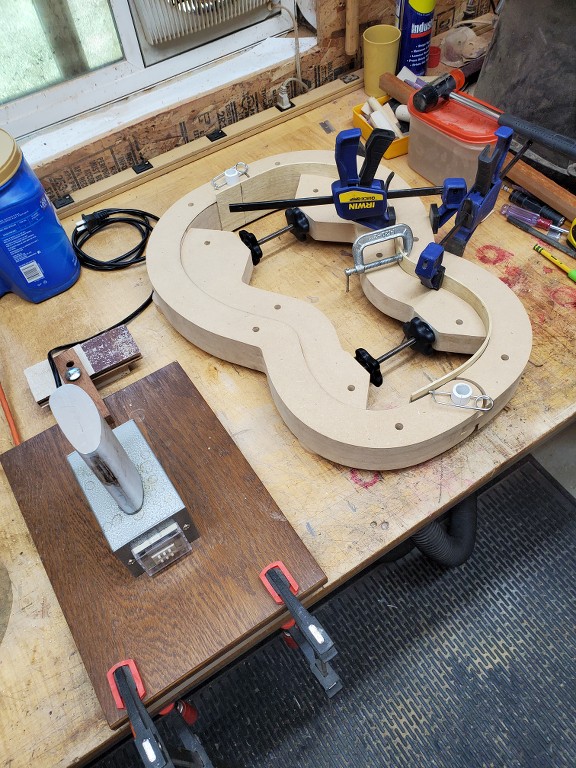

. Soo, being me, I decided to test it out. I have some white limba lying around and an LMI mold for a parlour guitar body. Once I thinned down some 3" wide sides I broke out the medieval torture device.

. Then I set it aside for a bit to cure. Meanwhile preparing some blocks for the head and tail which I then glued in place.

. Once that was done I started adding kerfed lining, which gives you more gluing surface for the top and back.

. More to come shortly.................... :turtle:

Greeting's Folks. Got me a new toy that started it up again.

. This is a lot better than my old one. It's actually made to cut hardwood, not just soft pine and it can reduce a piece to 1/8 thick. The old one could only go down to 1/2 inch.

. Soo, being me, I decided to test it out. I have some white limba lying around and an LMI mold for a parlour guitar body. Once I thinned down some 3" wide sides I broke out the medieval torture device.

. Then I set it aside for a bit to cure. Meanwhile preparing some blocks for the head and tail which I then glued in place.

. Once that was done I started adding kerfed lining, which gives you more gluing surface for the top and back.

. More to come shortly.................... :turtle: