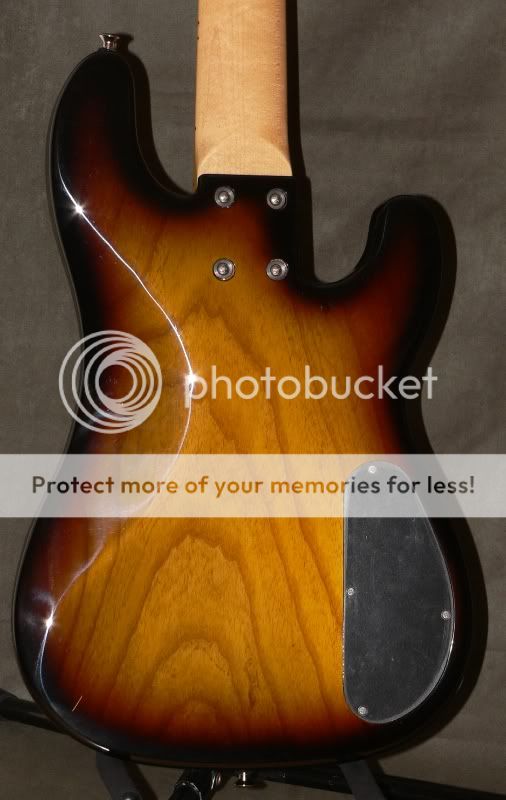

I'm going to order a soloist body and kws neck, and I'd like to have a contoured heel like in this old Lag Rockline.

My plan is to order both body and neck with no mounting holes, and let local guitar builder do the contoured heel.

Do you guys see any reasons why I shouldn't do this? Is it possible that upper left screw hits the truss rod? Anything else I haven't notice? Neck plate modification is no problem, I can do that by myself.

I'm doing this because I have small hands and I play a lot in upper frets. I have a Warmoth Les Paul with contoured heel, but that Lag Rockline suits much better for my hands.

My plan is to order both body and neck with no mounting holes, and let local guitar builder do the contoured heel.

Do you guys see any reasons why I shouldn't do this? Is it possible that upper left screw hits the truss rod? Anything else I haven't notice? Neck plate modification is no problem, I can do that by myself.

I'm doing this because I have small hands and I play a lot in upper frets. I have a Warmoth Les Paul with contoured heel, but that Lag Rockline suits much better for my hands.