neverstock

Junior Member

- Messages

- 50

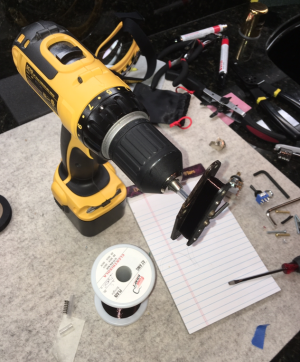

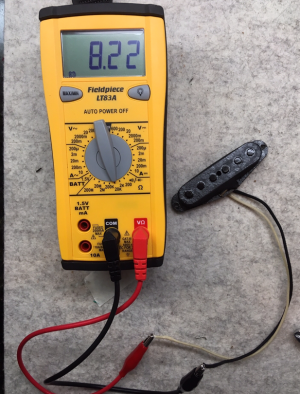

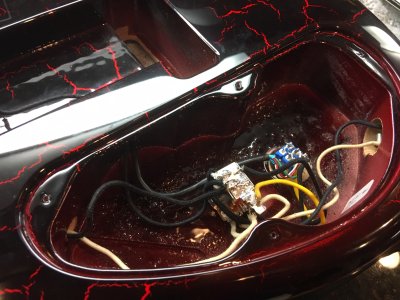

The Red Crackle is an inspiring finish in person. This an alder body, and I felt it looked like the top of lava flow. So I was inspired to wind pickups for it and decorate them as lava rocks using a black lacquer pen. The pickups have some interesting specs. Wound the single coil to 8.22k with 42AWG plain enamel wire in order to match the 9k bridge humbucker better. The humbucker is wound asymmetrically with poly on one coil and plain enamel in the other.

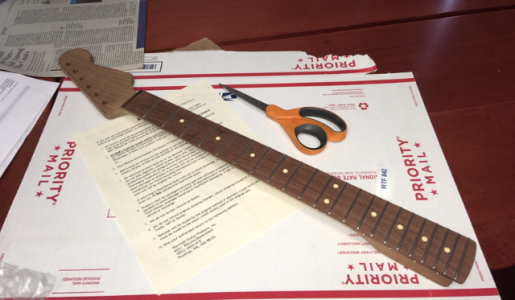

Have a really nice sounding toasted maple/ Madagascar Rosewood neck for it- rings like a marimba key. It it is the wrong color for lava flow. I will look to color it with potassium permanganate and/or transtint dye.

Have a really nice sounding toasted maple/ Madagascar Rosewood neck for it- rings like a marimba key. It it is the wrong color for lava flow. I will look to color it with potassium permanganate and/or transtint dye.